Man-machine cooperation assembly method and system with multi-mode switching function

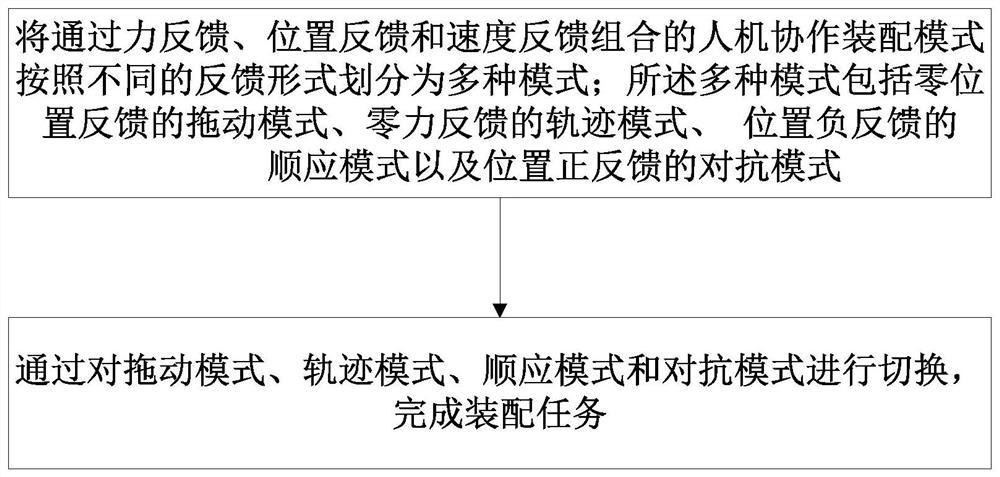

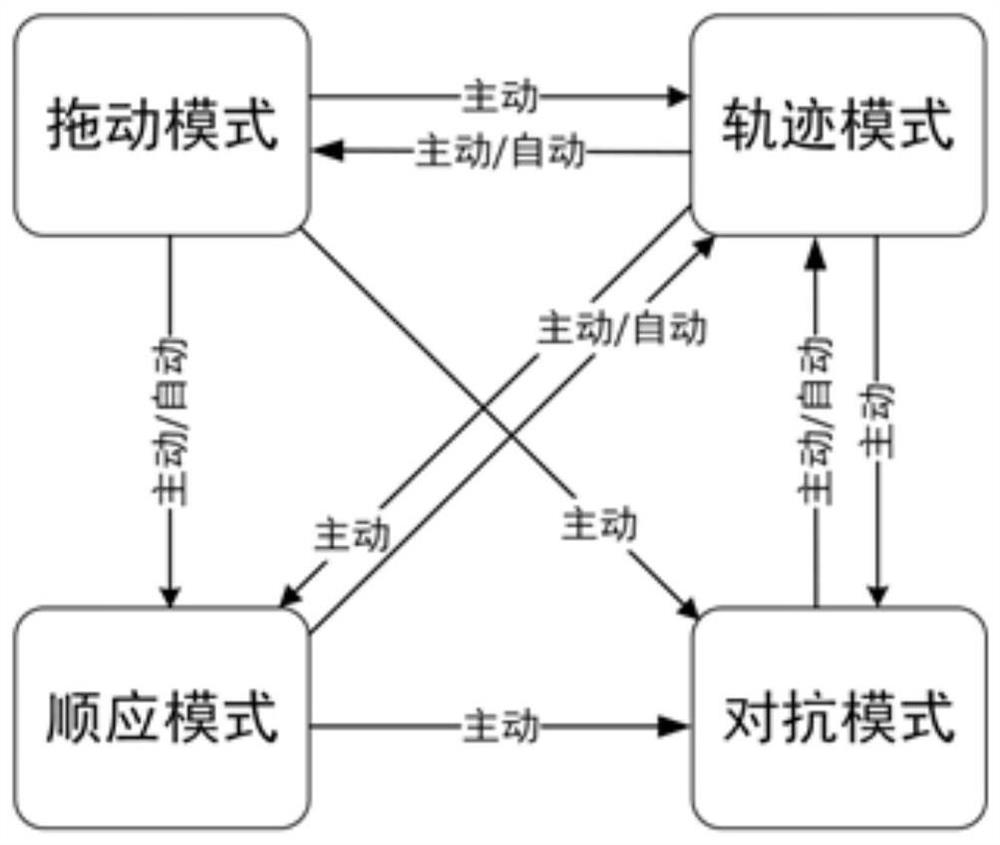

A technology of human-machine collaboration and switching functions, applied in the direction of manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as difficult to meet complex assembly tasks, single mode, etc., achieve good force compliance, expand the scope of application, and prevent accidental switching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

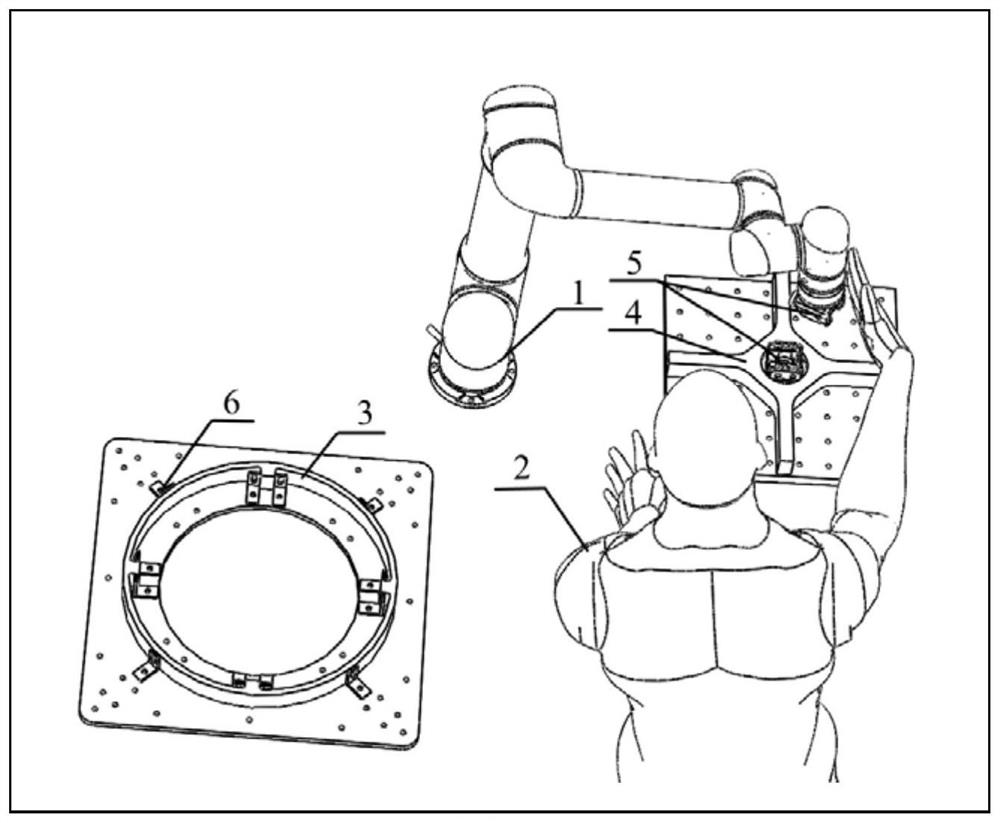

[0078] For precision bore shaft assembly, the assembly process has a definite assembly completion position, so the compliance mode is used for assembly. The fixed workpiece is clamped by the table fixing fixture. It has good repetitive clamping accuracy, can obtain assembly position information through one-time teaching, and can automatically assemble in trajectory mode in repeated assembly tasks. The moving workpiece and the end of the robot are equipped with quick-change fixtures, which can be snapped and released quickly through the quick-change fixtures, so the confrontation mode is used for fastening assembly. The position of the moving workpiece is uncertain, so it is dragged by the operator in the drag mode to the vicinity of the mating position.

[0079] like image 3 As shown, 1 is the robot body, 2 is the operator, 3 is the fixed workpiece, 4 is the moving workpiece, 5 is the quick-change fixture, 6 is the fixed workbench and the fixed fixture. like Figure 4 As ...

Embodiment 2

[0088] Bolt group fastening assembly. In the assembly task of fastening the connection of workpieces with a set of bolts. If one bolt is tightened first, the connected part is compressed and elastically deformed, and when the adjacent bolt is tightened, the pre-tightening force of the initially tightened bolt is reduced due to the elastic deformation of the connected part. Therefore, when the bolt group is tightened, it is usually divided into initial tightening, re-tightening and final tightening, and it needs to be carried out in a certain order.

[0089] In the compliance mode, the end of the robot is switched to a low-torque automatic screwing tool, and the robot automatically complies with the error to align the bolts with the threaded holes for initial screwing of the bolts. The bolts after the initial tightening cannot meet the pre-tightening force requirements, and retightening and final tightening operations need to be performed in the confrontation mode. The end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com