A high-density concrete product forming method

A molding method and technology of concrete products, which are applied in the direction of ceramic molding machines, auxiliary molding equipment, manufacturing tools, etc., can solve the problems of limited application range, low processability, low compactness, etc., and achieve improved compactness, effective degassing, good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

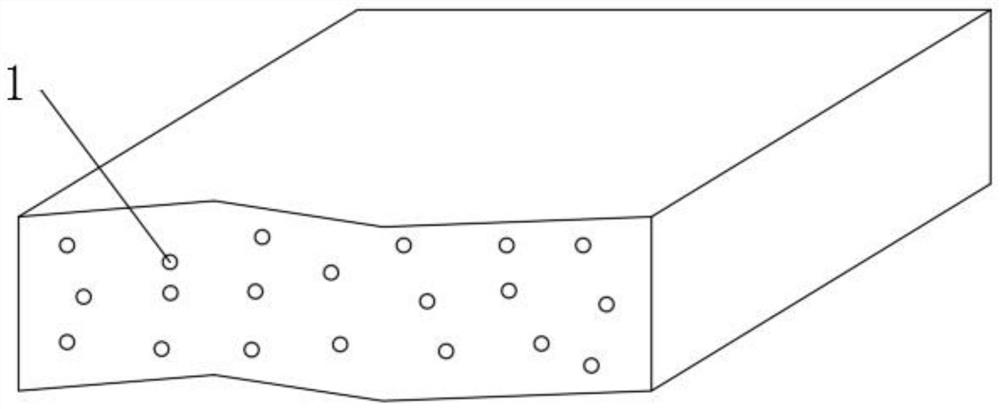

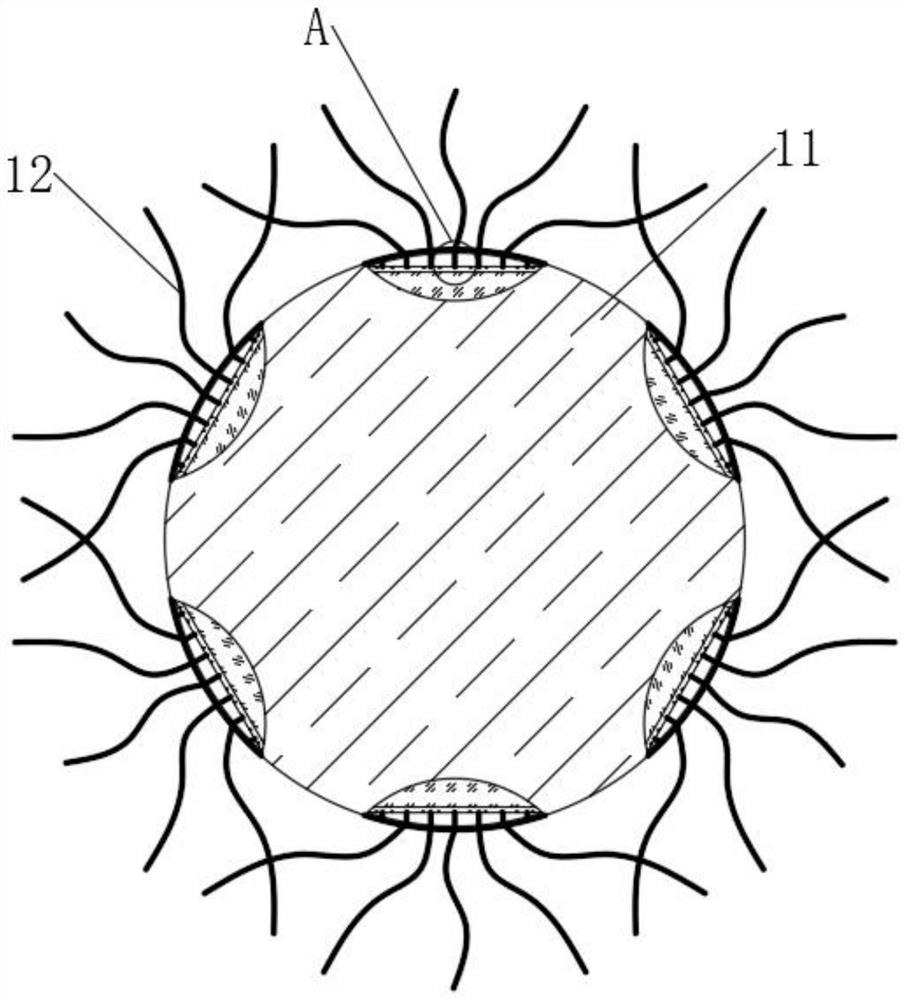

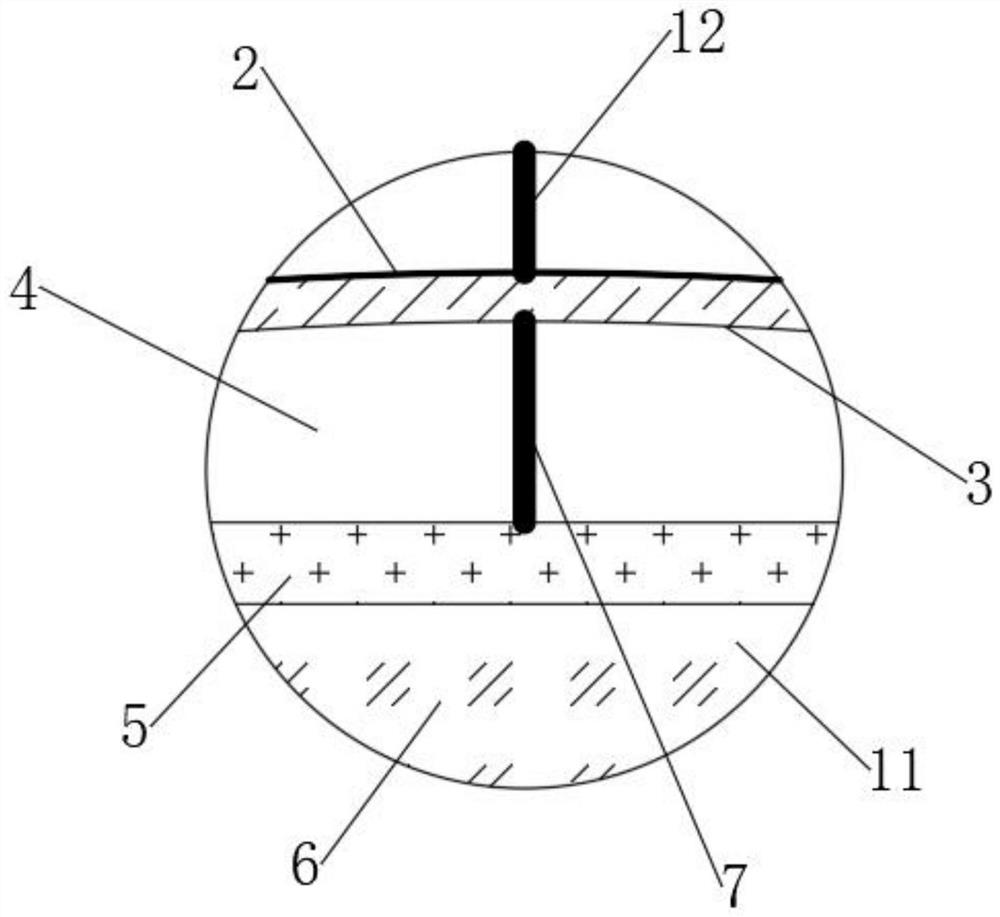

[0044] see figure 1 , a high-density concrete product molding method, comprising the following steps:

[0045] S1. Manually sort the recovered concrete materials, and crush the available materials obtained through sorting;

[0046] S2. Perform secondary screening on the crushed raw materials to obtain available recycled aggregates, and mix them with lightweight aggregates to obtain composite aggregates;

[0047] S3. Weigh the following raw materials in parts by weight: 30 parts of composite aggregate, 10 parts of cementitious material, 0.05 part of water reducing agent, 0.02 part of retarder, 0.01 part of early strength agent and 4 parts of water;

[0048] S4. Put the above-mentioned raw materials into the mixer for uniform stirring to obtain the mixture, pour the mixture into the mold of the concrete product, and put in an appropriate number of compacting balls 1;

[0049] S5. Vibrate the mixture in the mold. After the completion, the compacting ball 1 is guided to migrate ...

Embodiment 2

[0060] A method for forming high-density concrete products, comprising the following steps:

[0061] S1. Manually sort the recovered concrete materials, and crush the available materials obtained through sorting;

[0062] S2. Perform secondary screening on the crushed raw materials to obtain available recycled aggregates, and mix them with lightweight aggregates to obtain composite aggregates;

[0063] S3. Weigh the following raw materials in parts by weight: 35 parts of composite aggregate, 12 parts of cementitious material, 0.3 part of water reducing agent, 0.1 part of retarder, 0.05 part of early strength agent and 6 parts of water;

[0064] S4. Put the above-mentioned raw materials into the mixer for uniform stirring to obtain the mixture, pour the mixture into the mold of the concrete product, and put in an appropriate number of compacting balls 1;

[0065] S5. Vibrate the mixture in the mold. After the completion, the compacting ball 1 is guided to migrate and degas in ...

Embodiment 3

[0069] A method for forming high-density concrete products, comprising the following steps:

[0070] S1. Manually sort the recovered concrete materials, and crush the available materials obtained through sorting;

[0071] S2. Perform secondary screening on the crushed raw materials to obtain available recycled aggregates, and mix them with lightweight aggregates to obtain composite aggregates;

[0072] S3. Weigh the following raw materials in parts by weight: 40 parts of composite aggregate, 15 parts of cementitious material, 0.5 part of water reducer, 0.2 part of retarder, 0.1 part of early strength agent and 8 parts of water;

[0073] S4. Put the above-mentioned raw materials into the mixer for uniform stirring to obtain the mixture, pour the mixture into the mold of the concrete product, and put in an appropriate number of compacting balls 1;

[0074] S5. Vibrate the mixture in the mold. After the completion, the compacting ball 1 is guided to migrate and degas in the mixt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap