Thermal regeneration steel slag asphalt mixture and preparation method thereof

A technology for asphalt mixture and old asphalt mixture is applied in the field of thermally recycled steel slag asphalt mixture and its preparation, which can solve the problems of unutilized steel slag and RAP, achieve significant social and economic benefits, reduce costs, and improve low-temperature crack resistance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

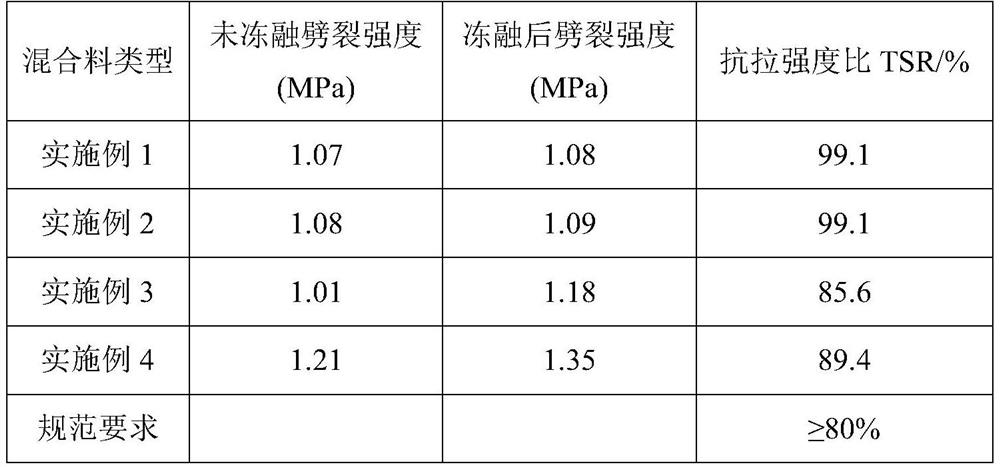

Embodiment 1

[0022] Embodiment 1: a kind of hot recycled steel slag asphalt mixture, including the following raw materials in weight: 3.98 parts of 70# road petroleum asphalt, 28.60 parts of AC-16 old asphalt mixture aggregates with a particle size range of 4.75-19mm, 6.22 parts Steel slag with a particle size range of 2.36-9.5mm, 59.5 parts of basalt rock with a particle size of 0.075-19mm, and 5.59 parts of limestone powder.

[0023] The preparation method of the above hot recycled steel slag asphalt mixture: (1) screen steel slag, old asphalt pavement materials and basalt rock through sieve holes; (2) heat steel slag and basalt rock together to 168°C; Heat the mixture aggregate and mineral powder together to 120°C; (4) Heat the asphalt to 148°C, then add steel slag, old asphalt mixture aggregate and basalt aggregate, and stir at 165°C Stir in the pot for 90s; (5) Add mineral powder to the mixture in step (4), and continue stirring for 90s to obtain hot recycled steel slag asphalt mixtur...

Embodiment 2

[0024] Embodiment 2: A kind of thermally recycled steel slag asphalt asphalt mixture, including the following raw materials in parts by weight: 4.31 parts of 70# road petroleum asphalt, 28.29 parts of old asphalt mixture aggregates with a particle size range of 4.75-19mm, and 12.26 parts of particle size Steel slag with a range of 2.36-9.5mm, 53.96 parts of basalt with a particle size range of 0.075-9.5mm, and 5.49 parts of limestone powder.

[0025] The preparation method of the above hot recycled steel slag asphalt mixture is the same as that of Example 1.

Embodiment 3

[0026] Embodiment 3: a kind of thermally recycled steel slag asphalt mixture, comprising the following raw materials in parts by weight: 4.37 parts of 70# road petroleum asphalt, 27.94 parts of old asphalt mixture aggregates with a particle size range of 4.75-19mm, and 18.11 parts with a particle size range of Steel slag of 2.36-9.5mm, 48.47 parts of basalt with a particle size range of 0.075-9.5mm, and 5.48 parts of limestone powder.

[0027] The preparation method of the above hot recycled steel slag asphalt asphalt mixture is the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com