Warp knitting machine needle piece

A technology of warp knitting machines and needles, which is applied in the field of warp knitting, and can solve problems such as increased wear, reduced economic benefits of enterprises, and increased force on needles, and achieves high machine speed, improved production efficiency, and stable knitting process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings of the description.

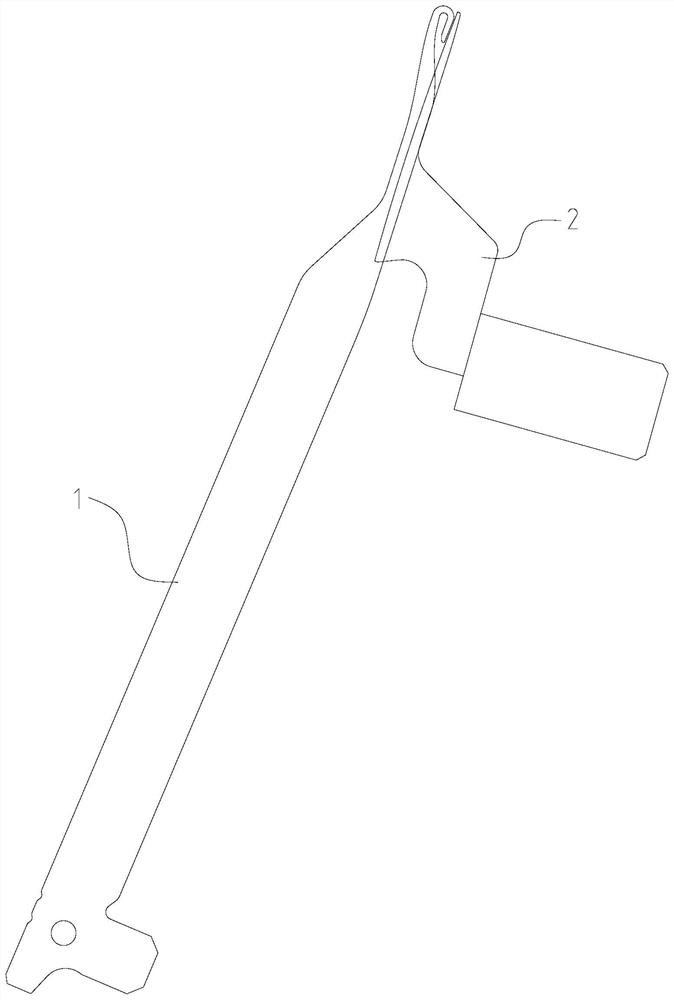

[0035] Such as figure 1 As shown, a warp knitting machine needle includes a grooved needle 1 and a needle core 2 matched therewith. The grooved needle 1 cooperates with the needle core 2 to realize knitting. The present invention is described for the slotted needle 1 whose model is 4341, and other types of slotted needles are also applicable to the inventive design method.

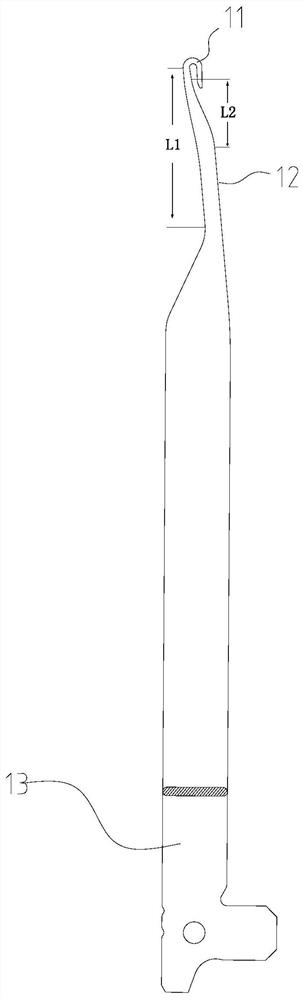

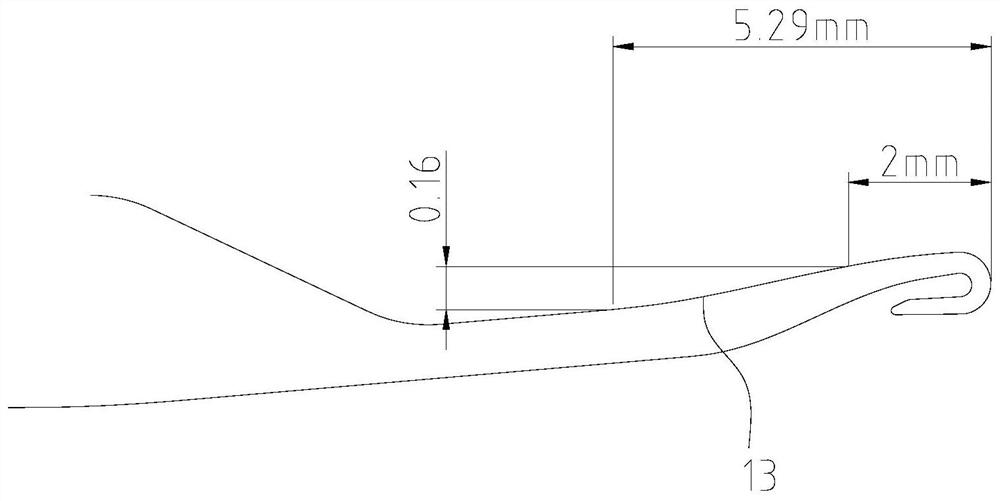

[0036] Such as figure 2 As shown, the slotted needle 1 includes a needle hook 11 , a needle bar 12 and a stitch 13 . The present invention optimizes the needle back contour area L1 and the needle groove contour area L2 of the groove needle, the needle back contour curve of the groove needle is composed of more than one function curve, and the needle groove contour curve of the groove needle is composed of more than one function curve , that is, to optimize the contour line fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com