Low-bath-ratio loose fiber dyeing device

A dyeing device and loose fiber technology, applied in liquid/gas/steam fiber/sliver/roving treatment, equipment configuration for textile materials, textiles and papermaking, etc., can solve problems such as difficult cleaning and contamination, and avoid contamination of dyes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention uses a low liquor ratio bulk fiber dyeing device to automatically complete the color matching of the colored liquid. The following examples will be used to further describe this solution in detail in conjunction with the accompanying drawings.

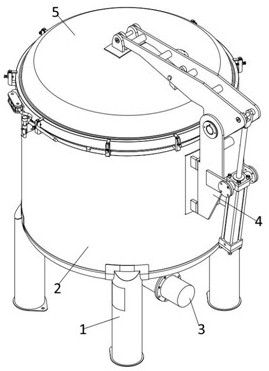

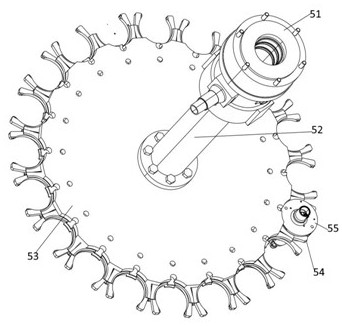

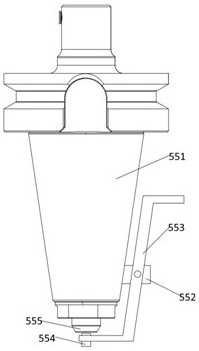

[0054] A low liquor ratio bulk fiber dyeing device includes: 1. support; 2. dyeing chamber; 21. lifting slide rail; 22. lifting motor; 23. lifting screw rod; Stirring shaft; 27, stirring paddle; 3, outflow pipe; 4, capping assembly; 42, capping connecting frame; 43, capping cylinder; 44, capping telescopic rod; 45, capping arm; 46, capping connection 5, observation cover; 51, toning motor; 52, toning rotating shaft; 53, toning turntable; 54, toning buckle; 55, toning vessel; 551, vessel shell; 552, vessel connecting block ; 553, utensil hinge rod; 554, utensil flow pipe; 5541, flow pipe wall; 5542, pipe wall connecting frame; 5543, butt joint; Cavity; 5553, head retraction spring; 5554, head retraction rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com