A method and system for detecting a knob shifter

A detection method and detection system technology, applied in the direction of components with teeth, transmission control, belt/chain/gear, etc., can solve the problems of parameter modification, negative driving experience, not doing well, etc., to reduce the The effect of bad rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

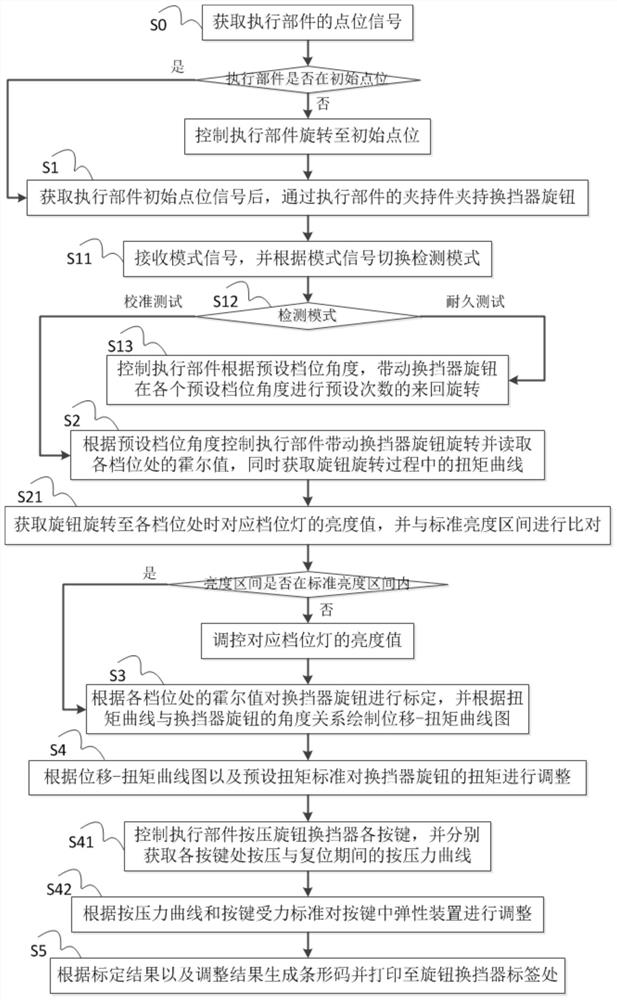

[0042] In order to avoid electronic shifters such as knob shifters, due to their self-protection mechanism, it is difficult for ordinary technicians to change them after leaving the factory. experience, so if figure 1 As shown, the present invention provides a method for detecting a knob shifter, comprising the steps of:

[0043] S1: After obtaining the initial position signal of the actuator, clamp the shifter knob through the clamp of the actuator;

[0044] S2: According to the preset gear angle, the actuator is controlled to drive the shifter knob to rotate and read the Hall value at each gear, and at the same time obtain the torque curve during the rotation of the knob;

[0045] S3: The shifter knob is calibrated according to the Hall value at each gear, and the displacement-torque curve is drawn according to the angular relationship between the torque curve and the shifter knob;

[0046] S4: Adjust the torque of the shifter knob according to the displacement-torque curv...

Embodiment 2

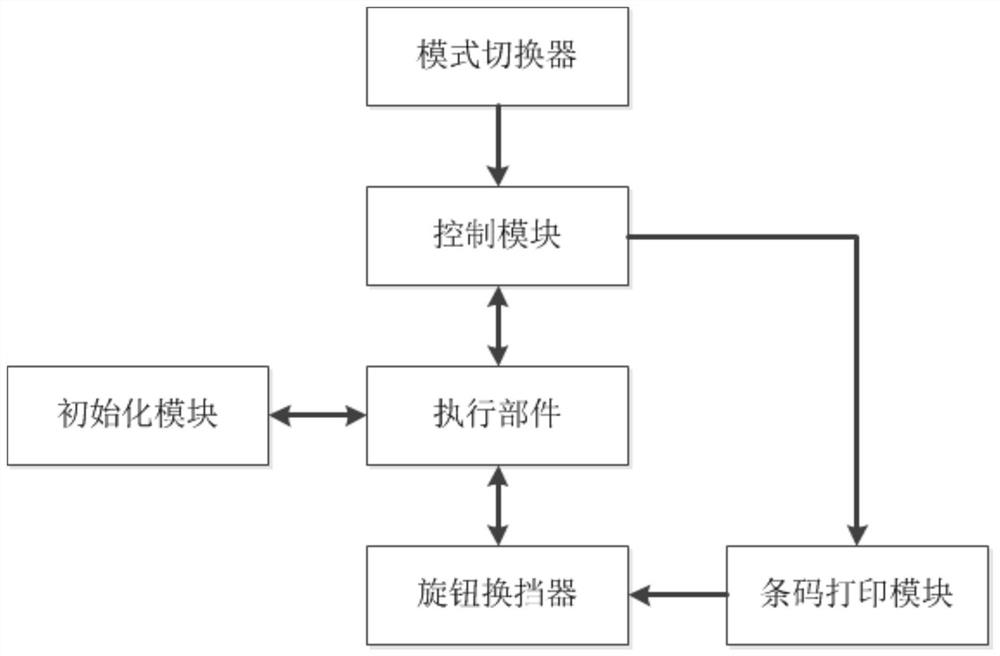

[0066] In order to better explain the technical content of the present invention, the present invention will be described in the form of a system structure, such as figure 2 As shown, a detection system for a knob shifter includes:

[0067] The control module is used to control the clamp of the actuator to clamp the shifter knob after acquiring the initial position signal of the actuator, and send the control signal to the actuator;

[0068] The execution component is used to drive the shifter knob to rotate at a preset gear angle according to the control signal, read the Hall value at each gear, and obtain the torque curve during the rotation of the knob;

[0069] The control module is also used to calibrate the shifter knob according to the Hall value at each gear, and draw the displacement-torque curve according to the angular relationship between the torque curve and the shifter knob, and at the same time according to the displacement-torque curve and The preset torque s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com