Organic waste gas treatment device

A treatment device, organic waste gas technology, applied in the direction of combustion method, combustion type, incinerator, etc., to achieve the effect of ensuring the filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

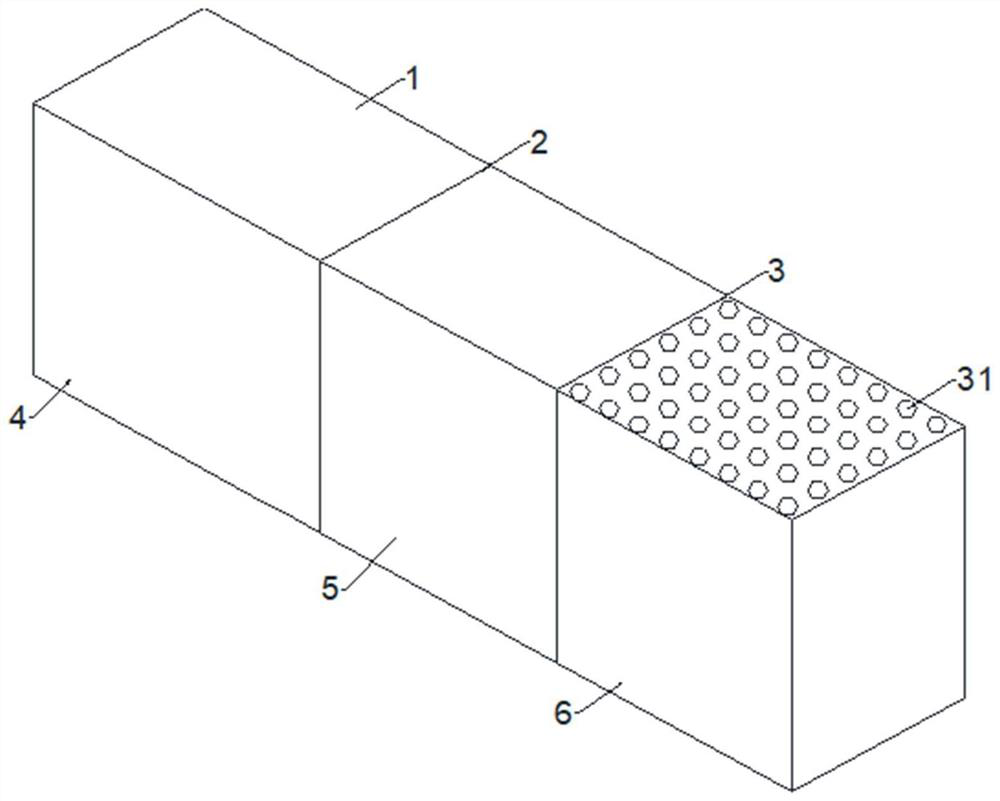

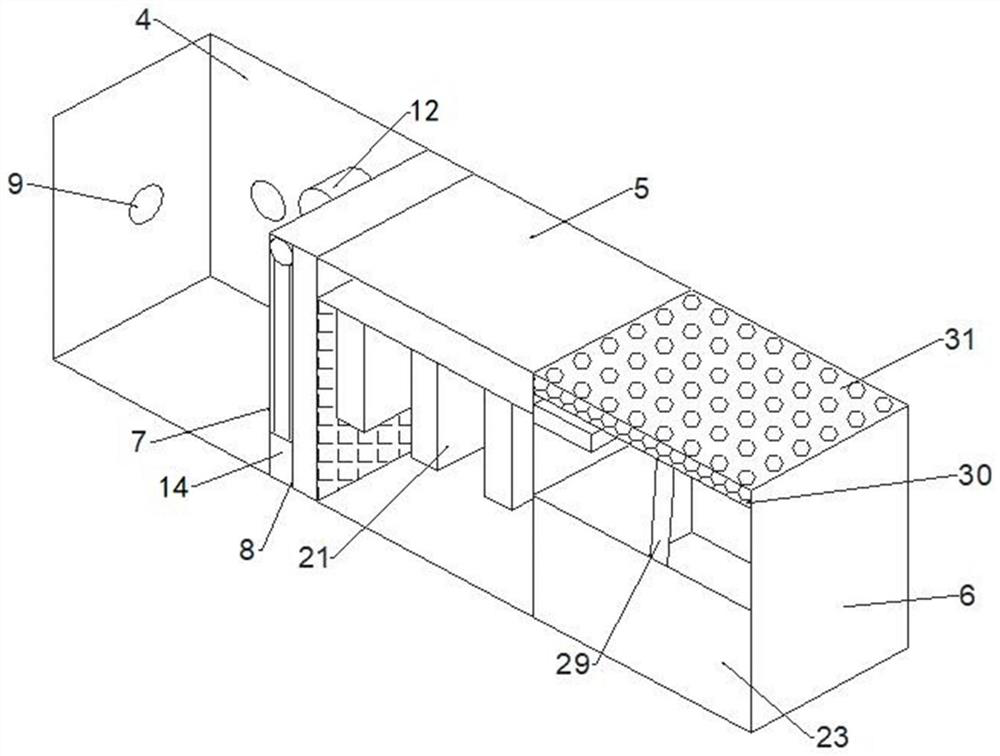

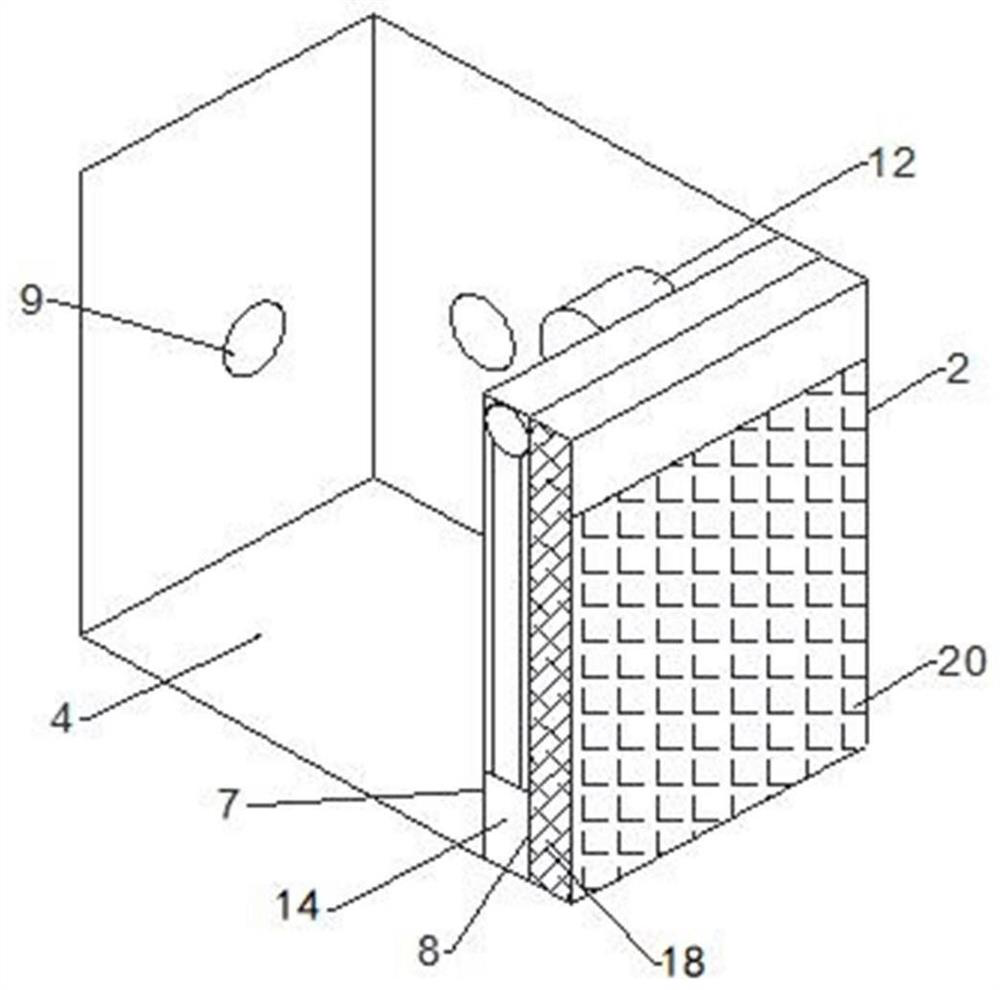

[0036] refer to Figure 2-5 Specifically, two flame spray nozzles 12 for injecting flames are arranged in the combustion chamber 4; the combustion chamber 4 is divided into a first chamber and a second chamber by a first filter screen 7 and a second filter screen 8 chamber and the third chamber; the left side wall in the first chamber is provided with a waste gas inlet 9; The air outlet communicates with the first chamber, and a flame retardant 11 is installed at the air outlet of the first fan 10; two flame retardants are installed on the right side of the rear side wall in the first chamber from top to bottom. Nozzle 12, two burners 13 are fixed on the rear side wall of the first chamber, and the burners 13 communicate with the flame nozzle 12 respectively; a water tank 14 is arranged in the second chamber, and the water tank 14 is provided with water curtain 15, and described water tank is provided with water pump 16, and described water pump 16 communicates with described...

Embodiment 2

[0038] refer to Image 6 , Specifically, the top of the filter bag cavity 5 is separated from the clean air chamber by the fourth partition 19; the first partition 2 is provided with a first air outlet 20, and the first hole 20 is located in the first partition 20. Under the four partitions 19; the filter bag 21 is fixed on the bottom surface of the fourth partition 19 from left to right; the top of the fourth partition 19 is provided with a plurality of hollow first air pipes 22, and the first air pipes One end of 22 passes through the fourth partition 19 and communicates with the filter bag 21; the waste gas dried by the desiccant 18 enters the filter bag cavity 5, and the organic waste gas is treated by the filter bag 21. The secondary filtration effectively adsorbs and intercepts solid substances such as dust in the gas, and discharges them into the clean air chamber through the first air pipe 22 .

Embodiment 3

[0040] refer to Figure 7 , specifically, a hollow tube 24 is placed in the lysate tank 23, and a plurality of second air outlet holes 25 are provided on the hollow tube 24; plate 26; the second fan 27 is fixed on the fixed plate 26, and the air suction port of the second fan 27 communicates with the clean air cavity through the second air pipe 28; the air outlet of the second fan 27 passes through the third Trachea 19 is communicated with described hollow pipe 14; The inner top wall of described solution box 23 is provided with activated carbon layer 30; On the top wall of described solution box 23, a plurality of third air outlet holes 31 are provided; The waste gas in the cavity is transported into the hollow pipe 24 through the second fan 27, and discharged into the solution tank 23 through the second air outlet 25; the waste gas dissolved and adsorbed by the solution rises through the After the activated carbon layer 30 is filtered again, it is discharged through the thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com