Closed cooling tower

A closed cooling tower, water cooling box technology, applied in water shower coolers, direct contact heat exchangers, heat exchange equipment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

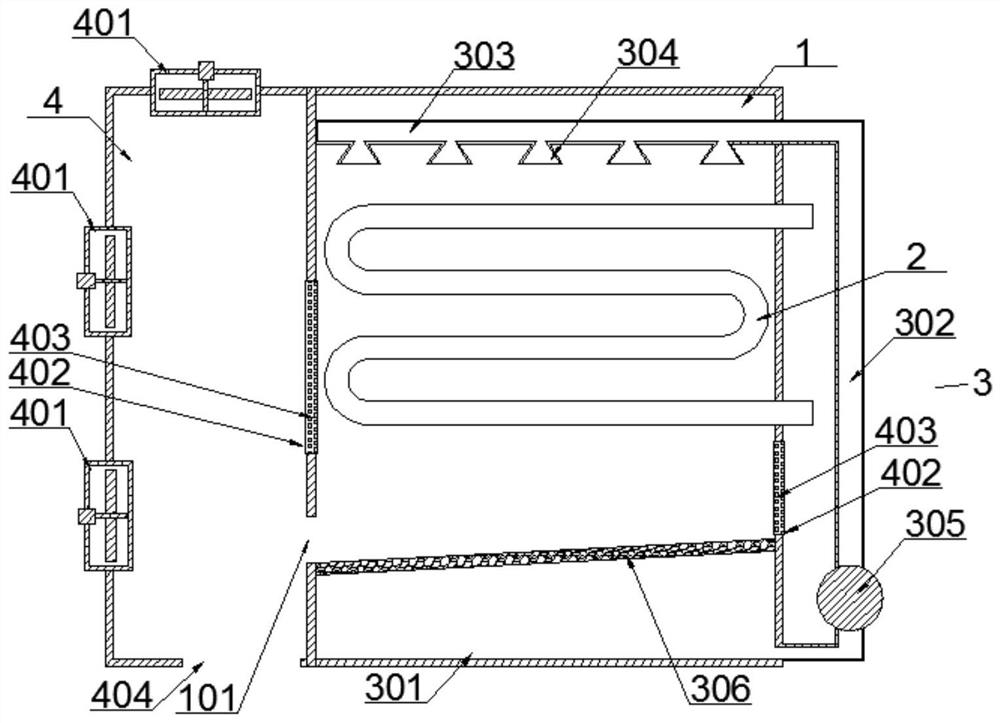

[0020] The structure of this embodiment, such as figure 1 As shown, a closed cooling tower includes a water-cooled box 1, a coil pipe 2 fixed in the middle of the water-cooled box 1, and a water spray device 3. A water tank 301 , a filter plate 306 is fixed between the water collecting tank 301 and the water cooling box 1 , and an air cooling box 4 independent from the water cooling box 1 is fixed on the left outer wall of the water cooling box 1 .

[0021] When the water washes down the scale on the coil 2, the water enters the water collecting tank 301, and the scale is intercepted by the filter plate, preventing the scale from entering the water collecting tank 301 and then entering the spray pump, causing the spray pump to be blocked; independent of the water cooling box 1 The fixed air-cooled box 4 prevents water from evaporating directly from the fan 401 port, which affects the heat exchange effect, and also prevents sundries from directly entering the water-cooled box 1...

Embodiment 2

[0023] In this embodiment, on the basis of Embodiment 1, further, the water spraying device 3 further includes a water delivery pipe 302 that is connected and fixed at one end to the water collection tank 301 and bent vertically upwards, and the other end of the water delivery pipe 302 is connected and fixed There is a water spray pipe 303 extending horizontally into the water cooling tank 1 and located on the upper side of the coil pipe 2. The bottom wall of the water spray pipe 303 is connected and fixed with 2 to 8 nozzles 304, and the bottom end of the water delivery pipe 302 is connected and fixed. There is a water spray pump 305, and the water spray pump 305 pumps the water in the water collection tank 301 into the water delivery pipe 302 and the water spray pipe 303, and then sprays it on the coil pipe 2 through the nozzle 304 to cool down, and the sprayed water falls into the water collection tank 301 Recycling within, saving resources.

Embodiment 3

[0025] In this embodiment, on the basis of Embodiment 1, further, the filter plate 306 is a slope-shaped structure inclined toward the left wall of the water-cooled box 1, and the wall of the water-cooled box 1 where the low end of the filter plate 306 is connected is opened. The first miscellaneous discharge port 101 , the first miscellaneous discharge port 101 communicates with the air-cooled box 4 , after the scale falls on the filter plate 306 , it slides down through the slope and is discharged from the first miscellaneous discharge port 101 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com