Environment-friendly treatment device for building concrete garbage

An environmental protection and concrete technology, applied in grain processing, solid separation, sieve, etc., can solve the problems of affecting the use of the device, blockage, different sizes, etc., and achieve the effect of preventing the blockage of the discharge port.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

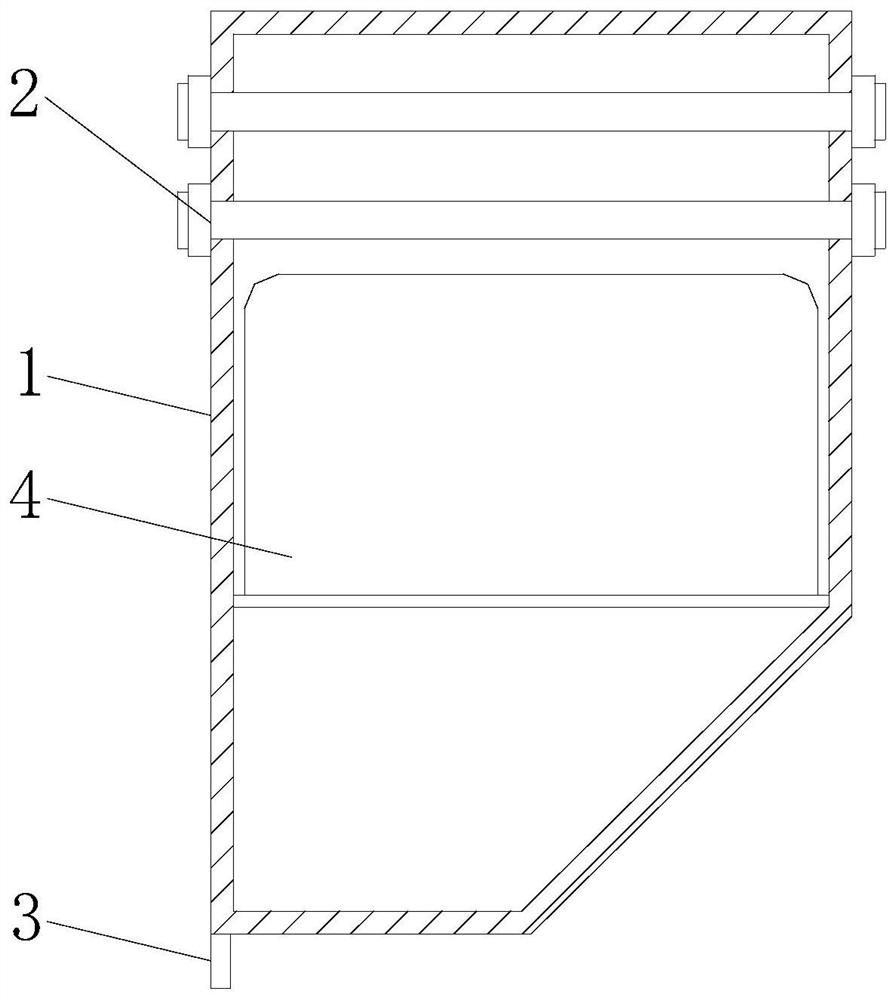

[0037] This embodiment provides an environmental protection treatment device for construction concrete waste, which includes a feed hopper 1, a crusher 2 and an equalizing plate 3. A rotating part with a screening function is connected inside the feeding hopper 1, and one end of the rotating part is connected with a crushing device. Functional accessories.

[0038] The environmental protection treatment device for construction concrete waste provided in this embodiment, puts the waste concrete into the hopper 1, and the waste concrete is broken by the crusher 2, and the broken waste concrete becomes granules and powder, such granules and The powder enters the inside of the rotating part through the screw on the top of the rotating part, and then the rotating part rotates to make the concrete particles and powder thrown out to the inner wall of the rotating part by the centrifugal force, wherein the concrete particles follow the inner wall of the rotating part and gradually rota...

Embodiment 2

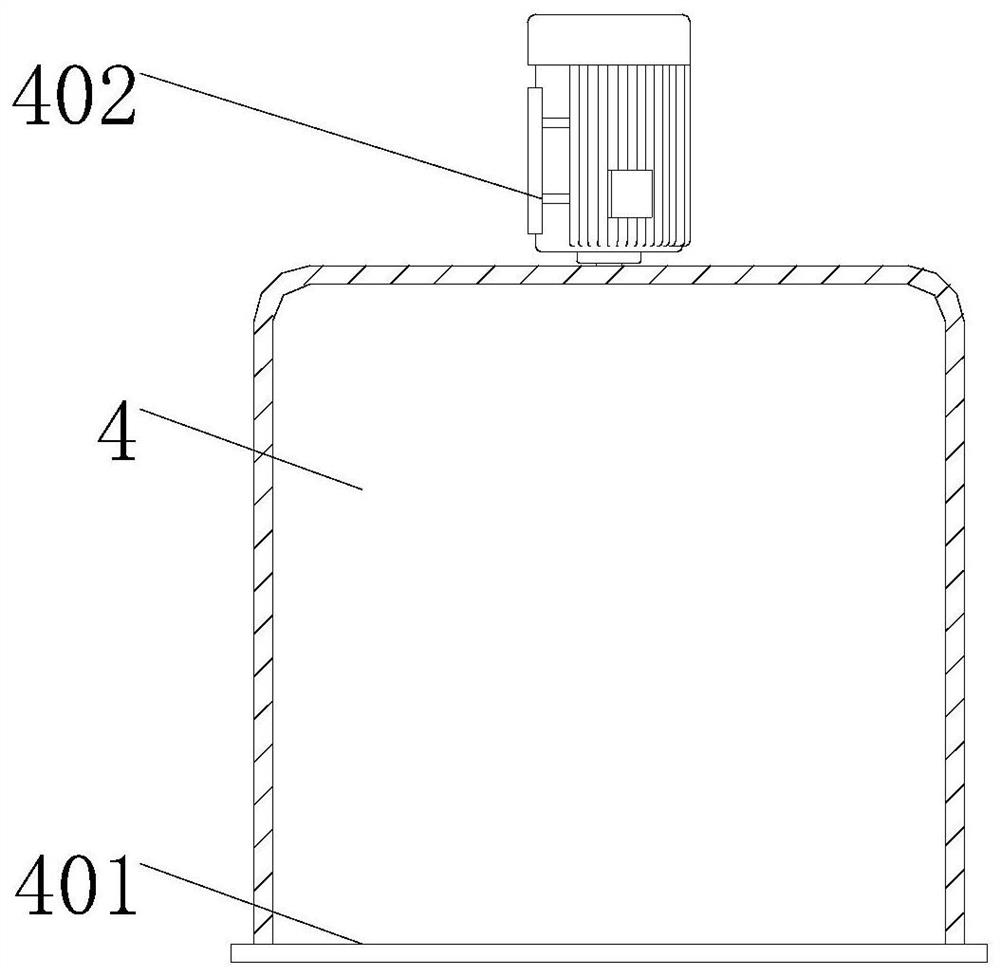

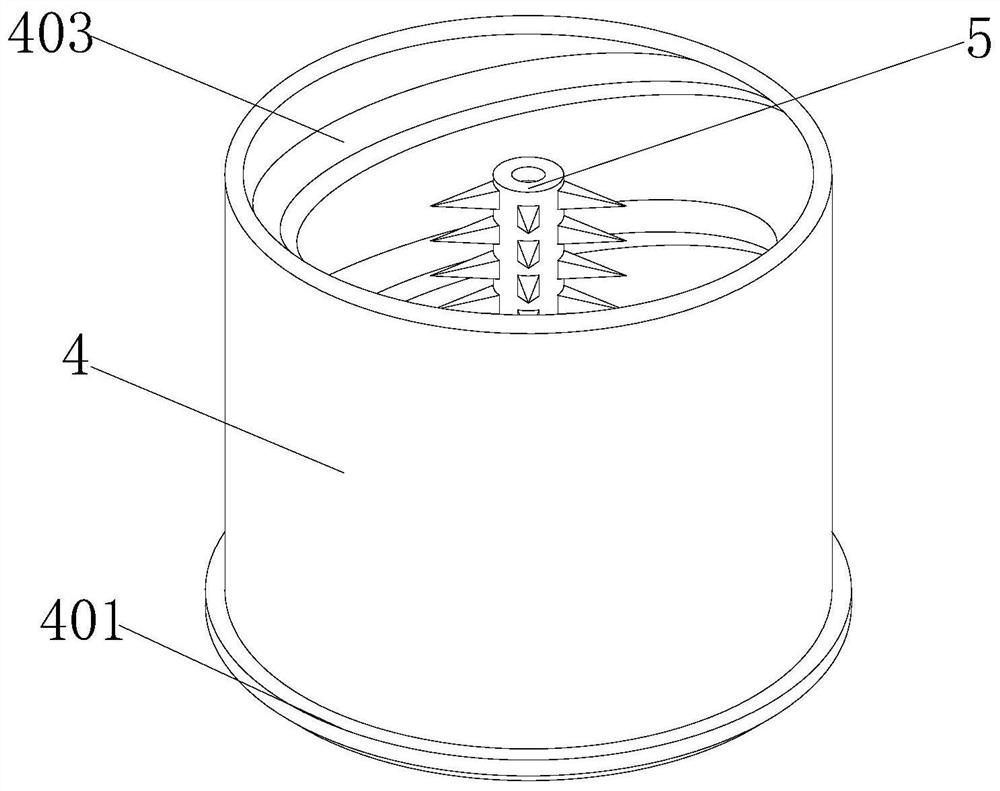

[0041] The difference between this embodiment and Embodiment 1 is that the rotating parts in this embodiment include crushing barrel 4, slider 401, motor 402, fixing bar 403, screen 4031, fixing bar 404 and baffle plate 405, and the outer side of crushing barrel 4 A slider 401 is connected below, a baffle 405 is connected above the inside of the crushing bucket 4, a fixing bar 404 is connected to the upper surface of the baffle 405, a motor 402 is connected to the center of the upper surface of the baffle 405, and a fixing bar is connected to the inner wall of the crushing bucket 4 403, a screen 4031 is installed on the upper surface of the fixed bar 403; the motor 402 adopts an ip68 motor with protection level; It is tapered, and the upper surface and the bottom of the fixed bar 403 are provided with through holes; the mesh 4031 is a wire mesh with a mesh size of 60;

[0042] Among them, the waste concrete is put into the feed hopper 1, and the waste concrete is broken into c...

Embodiment 3

[0048] The difference between this embodiment and Embodiment 1 is that the auxiliary parts of this embodiment include a connecting roller 5, a fixed block 501, a connecting block 5011, an air bag 5012, a connecting rod 502, a spring 5021, and a push rod 5022. The outer surface of the connecting roller 5 is connected with Fixed block 501, the inner center of fixed block 501 is connected with airbag 5012, the left and right sides of airbag 5012 are connected with connecting block 5011, the inner center of connecting roller 5 is connected with connecting rod 502, the inner center of connecting rod 502 is connected with spring 5021, the spring The left and right ends of 5021 are connected with push rods 5022; the connection between connecting roller 5 and baffle plate 405 is provided with a through hole; the fixing block 501 is arranged in a tapered shape; the connecting block 5011 is arranged in a triangular shape; set up.

[0049] Among them, the waste concrete is broken by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com