Photosynthetic reactor fermentation tube for culturing microalgae

A technology for photosynthetic reactors and fermentation tubes, which is applied to specific-purpose bioreactors/fermenters, combinations of bioreactors/fermenters, photobioreactors, etc. To improve the fermentation efficiency and improve the discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

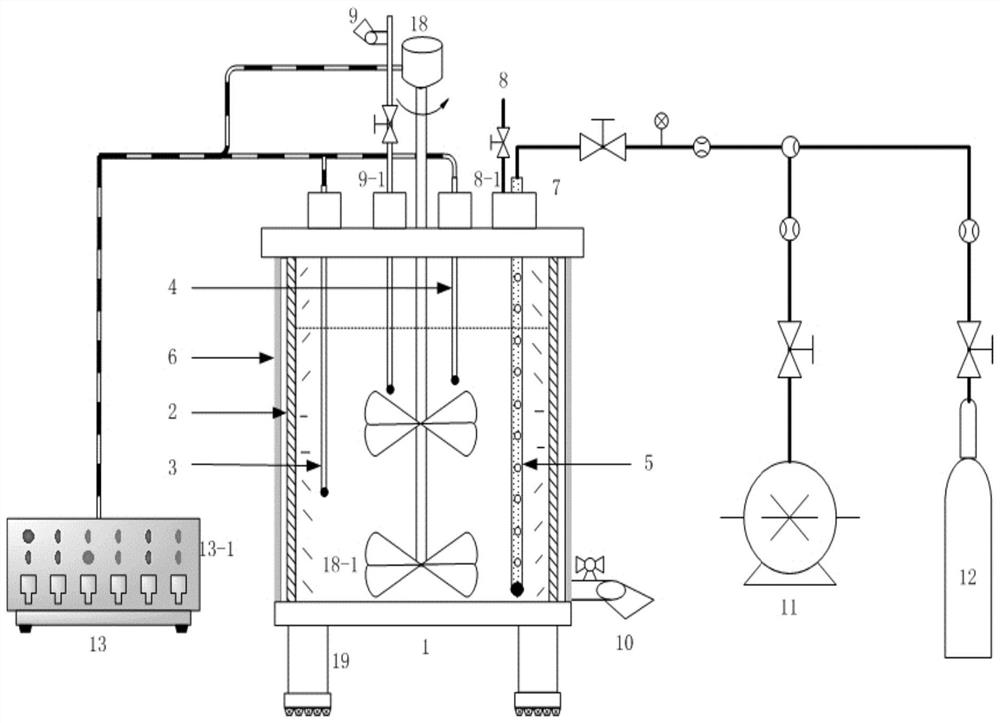

[0022] A photosynthetic reactor fermentation tube for cultivating microalgae, such as figure 1 As shown, it includes a fermenter main body 1, an LED lamp 2, a pH sensor 3, a temperature sensor 4, a gas concentration sensor 5, a temperature regulating plate 6, an air compressor 11, a gas cylinder 12 and a main control machine 13. The fermenter The main body 1 is used to hold photosynthetic microalgae. The inner wall of the fermenter main body 1 is provided with an LED light 2, and the microalgae in the fermenter main body 1 can receive the light emitted by the LED light 2. The inner wall of the main body 1 of the fermenter is designed to be opaque. The shape of the main body 1 of the fermenter is preferably cylindrical, and its size can be: 50 cm high, 24 cm in diameter, and 20 L in volume. It only needs to satisfy the technical effects to be achieved by the embodiments of the present invention. The LED lamp 2 has a complete waterproof function and can work normally in liquid ...

Embodiment 2

[0036] In this example, the photosynthetic reactor fermenter proposed in Example 1 is used to cultivate Spirulina. Spirulina is a kind of algae with fast growth rate, strong adversity tolerance and high content of functional substances. It is commonly used in the study of biological carbon fixation. Algal species, the spirulina of the present embodiment selects Spirulina dunnii (Spirulina dunnii), takes Spirulina dunnii as an example, optimizes the culture conditions, improves the output of phycobiliprotein; cultivating Spirulina specifically includes the following steps:

[0037] Step 1: Temperature Optimization

[0038] The Spirulina seed solution was inoculated in the main body of the fermenter, and the initial cell density was controlled at 1.2×10 6 In the range of / mL, the pH is controlled within the range of about 8, air is introduced, and the DO value (dissolved oxygen) is controlled within the range of 30% to 50%, with 5°C as the interval, set 20°C, 25°C, 30°C, The te...

Embodiment 3

[0046] In this embodiment, the photosynthetic reactor fermenter proposed in Example 1 is used in this embodiment to cultivate Nitzschia laevis. The Nitzschia laevis in this embodiment is selected from UTEX 2047, Austin, Texas, University of Texas Algae Culture library, the medium used is LDM medium, and the composition ratio is 1g tryptone, 892mL artificial seawater, 100mL Bristol solution, 6mL PIV metal solution, 1mL biotin stock solution (25.0×10 -5 g / L) and 1mL vitamin B12 (15.0×10 -5 g / L), all fermentation media were added with 120mg / L Na 2 SiO 3 9H 2 O, 0.68g / L NaNO 3 And 5g / L glucose, cultivating Nitzkiri specifically comprises the following steps:

[0047] S1. Adjust the medium to pH 8.5 and autoclave at 121°C for 20 minutes. The cell suspension was centrifuged at 3000 g for 5 min, and the cell pellet was washed twice with distilled water before being transferred to the main body of the fermenter, which contained fresh LDM medium. Add pre-sterilized glucose stock ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com