A multi-functional electric extrusion gun

A multi-functional, electric technology, applied to the device and coating of the surface coating liquid, can solve the problems of the grab bar being easily retreated by external force factors, consuming a large amount of electricity, and slowing the glue pushing speed, so as to prevent the difficulty of squeezing glue. , the effect of saving electric energy and speeding up the speed of pushing glue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

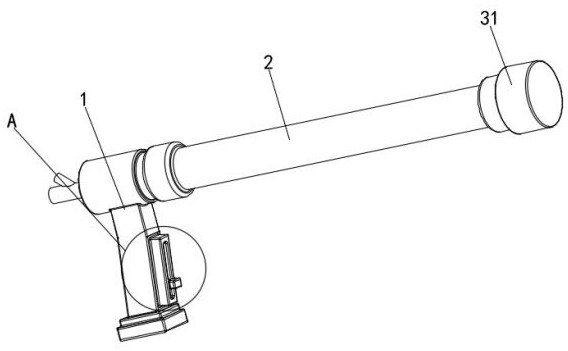

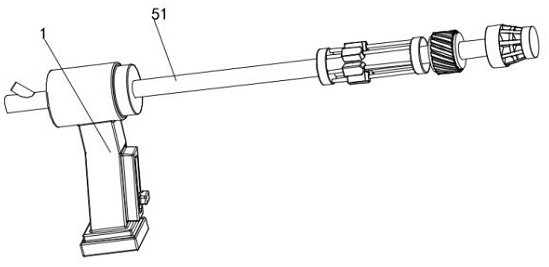

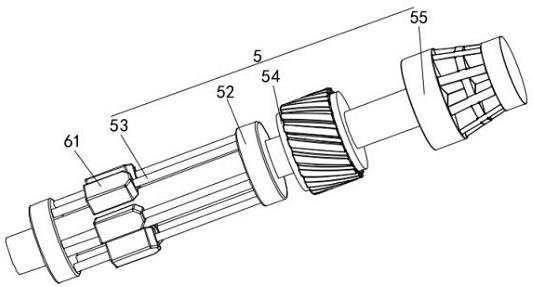

[0029] See Figure 1-7 A multi-function electric squeezing gun comprising a gun body 1, characterized in that the right side of the gun body 1 is connected to the barrel 2, the right side of the bobbin 2 is fixedly connected to the adjustment assembly 3, and the adjustment assembly 3 includes a circle. The cartridge 31, the inner side of the circular cassette 31 is rotated connected to the track disk 32, and the right side of the track disk 32 is fixedly coupled with the first magnetic block 36, and the outer side of the first magnetic block 36 is provided with a control chamber 35, the inner side wall of the control chamber 35 and The first coil 37 is fixed to the right of the first magnetic block 36, and the slot corresponding to the sliding block 33 is opened by the track disk 32 such that the track disk 32 can be slidable while rotating, The front side of the track disk 32 is rotatably connected to the sliding block 33, and the movable assembly 4 is fixed to the right side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com