Nozzle provided with anti-blocking device and used for injection molding machine

An injection molding machine and anti-blocking technology, which is applied in the field of injection molding machine nozzles, can solve problems such as delaying operations, easily affecting discharge, and poor use effects, and achieves the effects of preventing material blockage, improving stability, and improving scraping quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

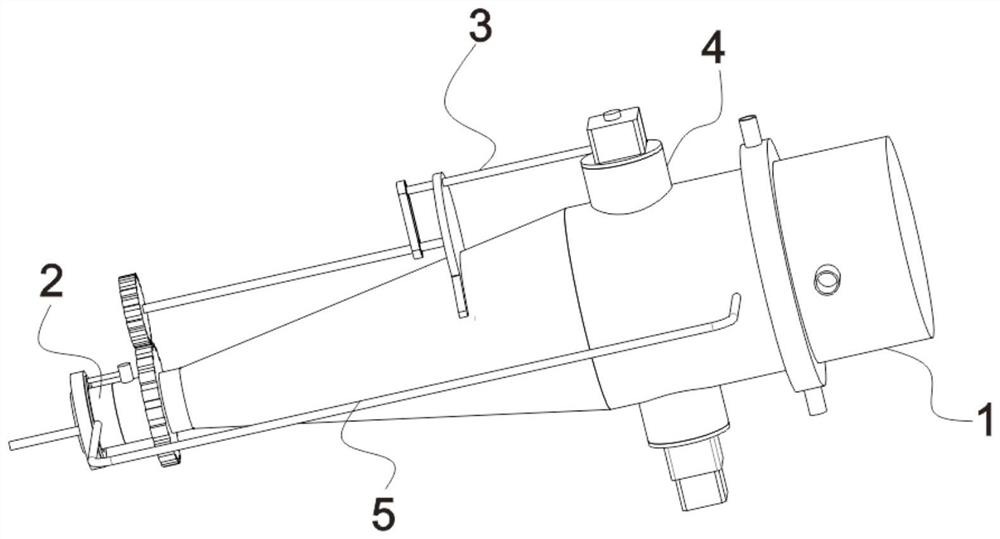

[0025] see Figure 1-5 , the present invention provides the nozzle for injection molding machine with anti-blocking device (the electrical components among the present invention are all connected with external power supply by wire), comprising,

[0026] Shell 1, the right section of the shell 1 is cylindrical, and the left section is truncated. The left side of the shell 1 is provided with a nozzle 2, which is fixed to the shell 1 through a connecting frame 5. The connecting frame 5 is U-shaped. The top of the shell 1 and the The right side of the bottom is fixedly inserted with a fixed pipe 4 connected to each other, and the shell 1 is also provided with structures such as a feed inlet and a cooling water ring. "Anti-blocking device and its method of use" have been disclosed, and will not be described in detail here;

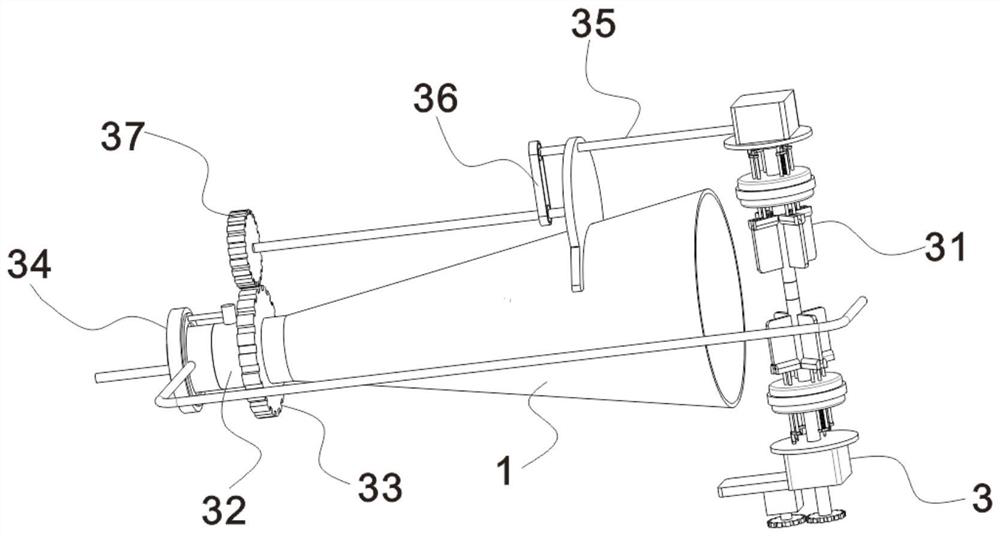

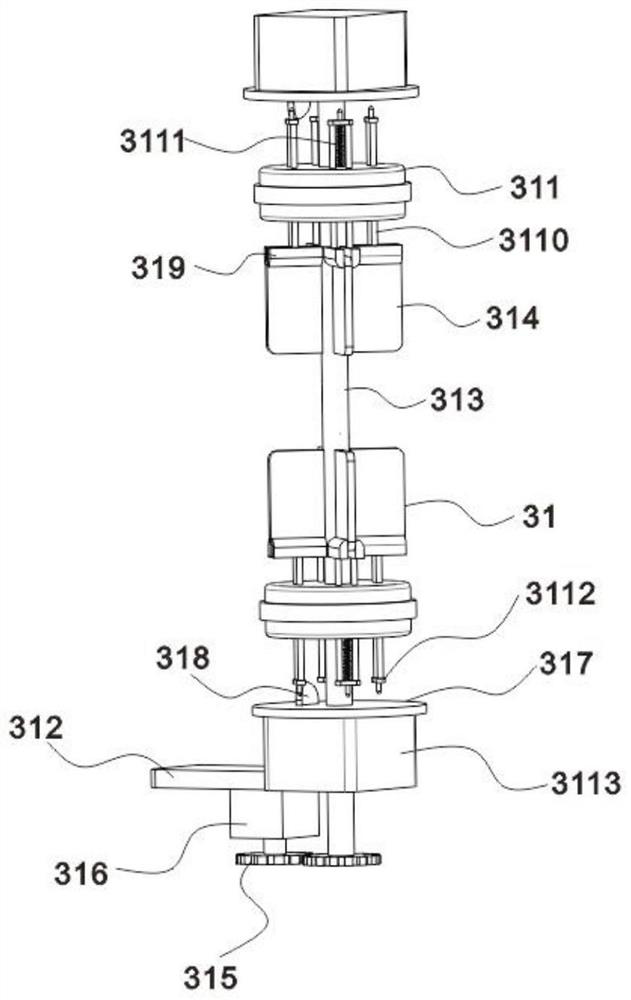

[0027] The anti-clogging part 3 includes a driving part 31 arranged in the fixed pipe 4. The left side of the housing 1 is provided with a connected follower ...

Embodiment 2

[0033] see Figure 4-5 , the scraping disturbing member 34 includes a hollow tube 341 fixedly inserted on the left side of the top of the follower ring 32, the hollow tube 341 rotates with the follower ring 32, the top and bottom of the hollow tube 341 are closed, and the hollow tube 341 is in a follower position. On the left side of the gear 33, the left side of the hollow tube 341 is fixedly inserted with a connected hollow assembly plate 345, the gas entering the hollow tube 341 can enter the hollow assembly plate 345, and the hollow assembly plate 345 is in the follower ring 32, hollow There is a groove on the top of the assembly plate 345, and a scraper 346 that fits the inner wall of the follower ring 32 and the inner wall of the nozzle 2 is movably inserted in the groove, and the bottom of the scraper 346 is fixed to the bottom of the groove by multiple sets of springs .

[0034] All the other structures are identical with embodiment 1

[0035] Compared with Embodimen...

Embodiment 3

[0037] see Figure 5 , the outer wall of the nozzle 2 is fixedly sleeved with an assembly ring 342, the assembly ring 342 does not rotate, and an annular cavity (not shown in the figure) is provided in the assembly ring 342, and an annular cavity communicating with the annular cavity is provided on the right side of the assembly ring 342. The ring mouth is provided with a rotating ring 344 through bearing rotation. The rotating ring 344 can rotate with the hollow pipe 341. The top of the left outer wall of the hollow pipe 341 is fixedly inserted with a connecting air pipe, and the other side of the connecting air pipe is fixedly inserted with a rotating ring. 344 and communicates with the annular cavity, so that the gas in the annular cavity can enter the hollow tube 341, the left side of the assembly ring 342 is fixedly inserted with a connecting hose 343 communicating with the annular cavity, and the other end of the connecting hose 343 is connected to the external gas supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com