Electromechanical brake amplifier

A braking force, electromechanical technology, applied in the direction of brakes, brake safety systems, brake transmissions, etc., can solve problems such as load and noise generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

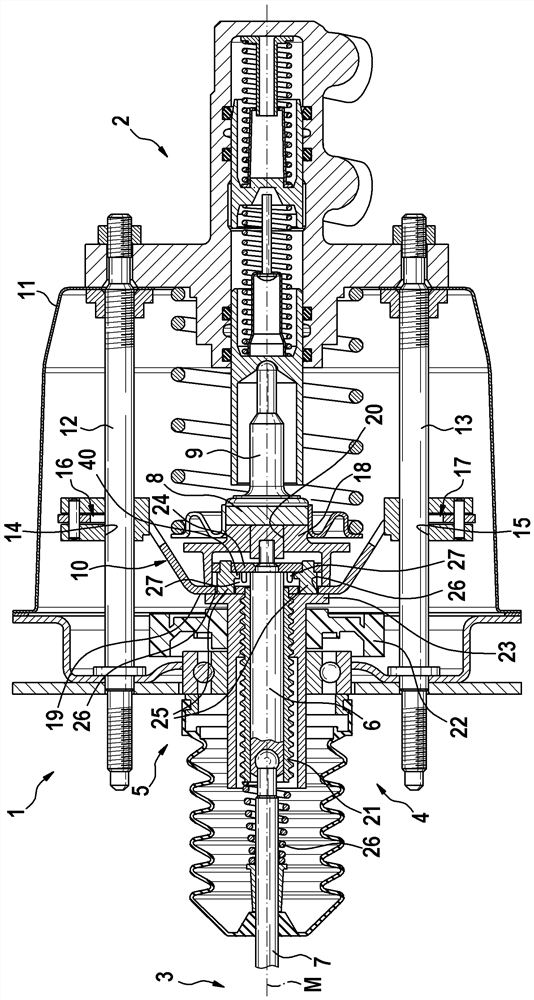

[0020] figure 1An advantageous brake booster 1 is shown in a simplified longitudinal section. Brake booster 1 can be coupled at one end to brake master cylinder 2 and at the other end to a brake pedal 3 of the motor vehicle, not shown here. Brake booster 1 serves to adjust the hydraulic pressure in master brake cylinder 2 as a function of brake pedal actuation. For this purpose, the brake booster 1 has an actuator 4 with an electric motor not shown and a spindle drive 5 via which the torque of the electric motor can be applied to the brake as thrust. On the connecting part of the moving pedal 3 and the brake master cylinder 2.

[0021] The brake booster 1 has a pressure piston 6 which is assigned to the brake master cylinder 2 at one end and is mechanically coupled at the other end to a coupling rod 7 which is connected to the brake It is connected with the brake pedal 3, and is moved by the operation of the brake pedal 3. One end of the pressure piston 6 is assigned to an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com