Transfer mechanism

A transfer mechanism and transfer device technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of uncompleted conveyor belts, easy to accumulate oil, difficult to clean, etc., to achieve easy maintenance, ensure hygiene problems, The effect of a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

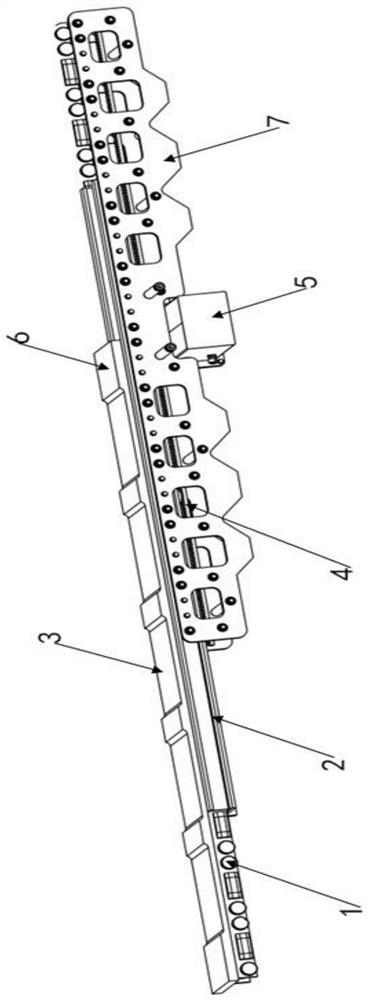

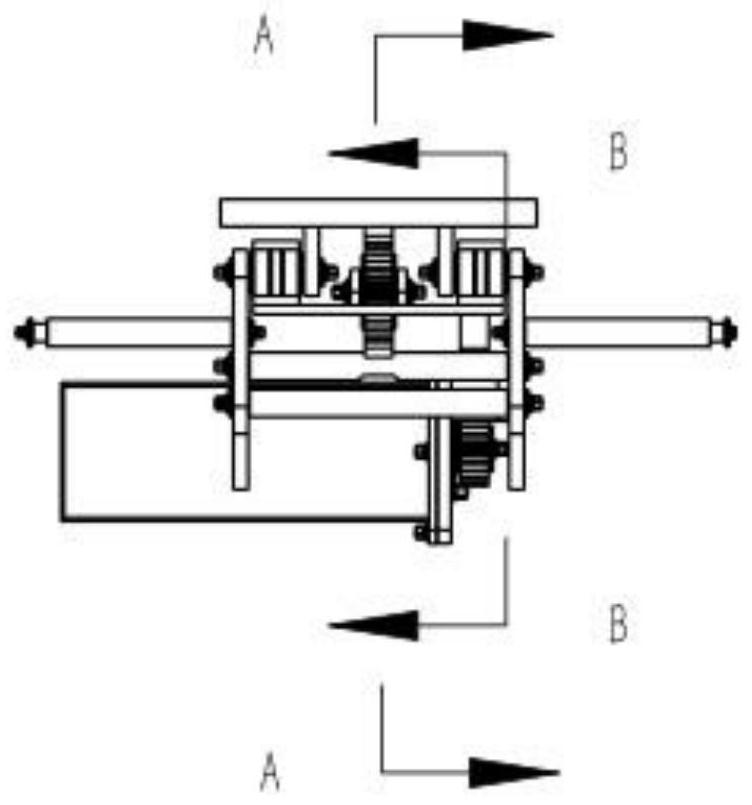

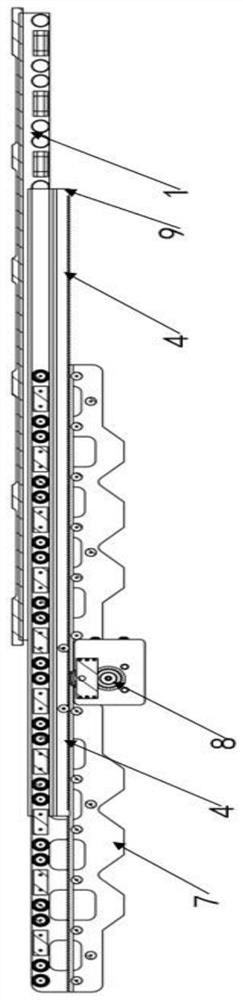

[0039]A transfer mechanism, which includes an up and down transfer device, a front and rear transfer device, and a left and right transfer device, the up and down transfer device includes a gantry frame 11, a cross bracket 20 is arranged on the gantry frame 11, the front and rear transfer devices are fixed on the bracket 20, and The frame 20 drives the front and rear transfer device to move up and down to realize the up and down transfer. The upper and lower rails are arranged between the two ends of the bracket 20 and the portal frame 11. The upper and lower rails are set as synchronous belts 16, and the synchronous belts 16 are arranged on the two outer sides of the portal frame 11. The portal frame 11 bottom ends are provided with synchronous shaft 28 and connect the synchronous belt 16 synchronous action of two outsides, synchronous shaft 28 is driven by motor, and left and right transfer mechanism is arranged on the upper end and the lower end of gantry 11. It also include...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that the slope of this embodiment is set at 2 degrees.

Embodiment 3

[0043] The difference between this embodiment and Embodiment 1 is that the slope of this embodiment is set at 10 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com