A kind of method of extracting chestnut husk brown pigment in chestnut shell and application in hair dye

A technology of chestnut shell and brown pigment, applied in chemical instruments and methods, medical preparations containing active ingredients, organic dyes, etc., can solve problems that do not conform to the concept of green chemistry, high cost, and deposits, and achieve good practice Application value, less damage, less environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

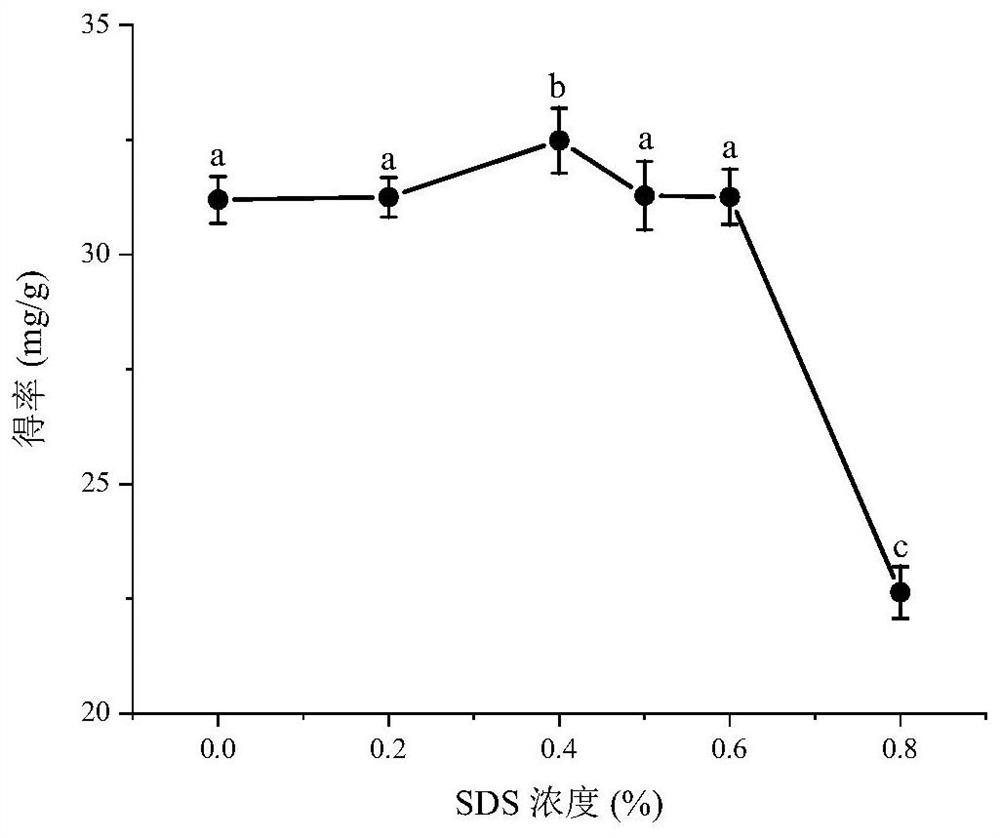

[0053] The present embodiment compares the effects of different concentrations of sodium dodecyl sulfate (SDS) on the extraction of chestnut husk brown pigment in the chestnut shell, and the specific process is as follows:

[0054] Take 0.2g chestnut shell powder respectively, add 0, 0.2, 0.4, 0.5, 0.6, 0.8wt% SDS, other conditions are fixed: particle size 60 mesh, 15wt% urea, V [Bmim]OAc / V 40%乙醇It is 1:1, the material-liquid ratio is 1:10g / ml, the ultrasonic temperature is 80°C, the time is 70min, the power is 350W, and the supernatant is taken after centrifugation.

[0055] The yields were determined at different SDS concentrations; the results are as follows figure 2 shown.

[0056] analyze figure 2 It can be seen that with the increase of SDS concentration, the yield increases. When the SDS concentration is 0.4 wt%, the yield is the largest, and when it exceeds 0.4%, the yield decreases; The amphiphilic molecular structure can significantly reduce the interfacial te...

Embodiment 2

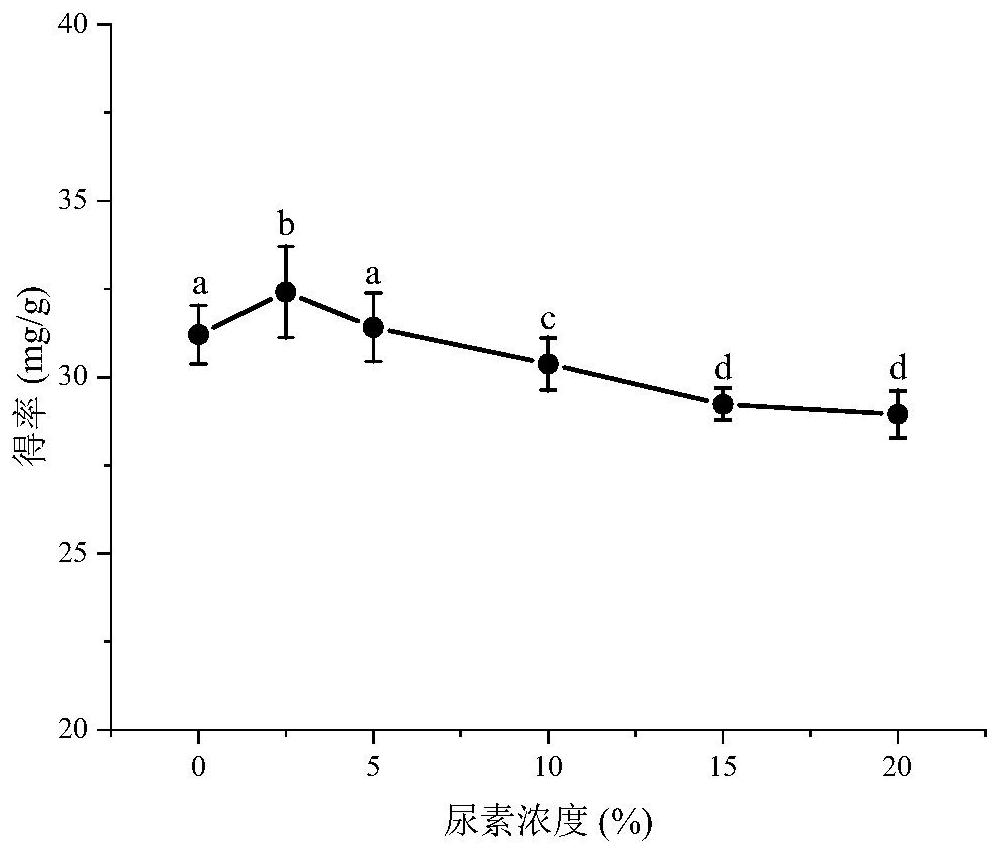

[0058] The present embodiment compares the influence of different urea concentrations on the extraction of chestnut husk brown pigment in the chestnut shell, and the specific process is as follows:

[0059] Take 0.2g chestnut shell powder respectively, add 0, 2.5, 5, 10, 15, 20wt% urea, other conditions are fixed: particle size 60 mesh, 0.4wt% SDS, V [Bmim]OAc / V 40%乙醇 It is 1:1, the material-liquid ratio is 1:10g / ml, the ultrasonic temperature is 80°C, the time is 70min, the power is 350W, and the supernatant is taken after centrifugation.

[0060] Determination of yields at different urea concentrations; results such as image 3 shown.

[0061] analyze image 3 It can be seen that with the increase of urea concentration, the yield increases. When the urea concentration is 2.5 wt%, the yield is the largest, and when it exceeds 2.5%, the yield decreases.

Embodiment 3

[0063] The present embodiment compares the effects of different solid-liquid ratios on the extraction of chestnut husk brown pigment in the chestnut shell, and the specific process is as follows:

[0064] Take 0.2g of chestnut shell powder respectively, the particle size is 60 mesh, the ratio of solid to liquid is 1:10, 1:20, 1:30, 1:40, 1:50g / ml, other conditions are fixed: 0.4wt% SDS, 2.5 wt% urea, V [Bmim]OAc / V 40%乙醇 1:1, ultrasonic temperature 80°C, time 70min, power 350W, and the supernatant was taken after centrifugation.

[0065] Determination of yield under different solid-liquid ratios; the results are as follows Figure 4 shown.

[0066] analyze Figure 4 It can be seen that when the ratio of solid to liquid is from 1:10 to 1:30, it may be because the amount of extracting solution is increased, which makes it easier to extract the polyphenols from the chestnut shell, so the yield increases significantly. However, when the solid-liquid ratio is 1:40, the yield d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com