Walking type leaf sucking, sweeping and bar pressing integrated equipment

A walking and leaf technology, applied in the direction of presses, cleaning methods, chemical instruments and methods, etc., can solve the problems of lack of dust removal devices, dusty, low efficiency, etc., to achieve the effect of solving dusty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

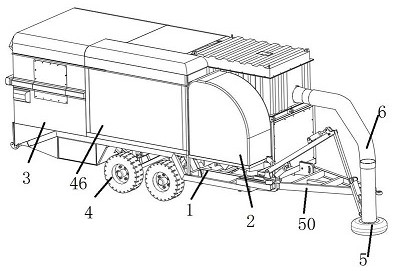

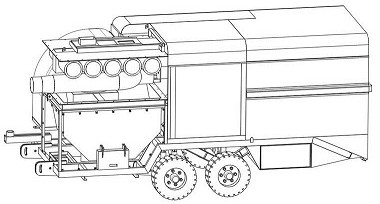

[0041] see Figure 1-3 , a kind of integrated equipment for walking leaf suction, sweeping and pressing rods, comprising a chassis 1, an operation room 2 is provided on the chassis 1, a suction device is provided on one side of the operation room 2, and a suction device is provided under the suction device. A leaf collecting and extruding device is provided, and the leaf collecting and extruding device is connected with the rear cargo box 3 through a belt conveying system, the rear cargo box 3 is located at the rear end of the chassis 1, and the front end of the chassis 1 is provided with a pulling device 50. A hydraulic device is fixed on the chassis 1, and the hydraulic device is fixedly connected to the adsorption hose 6 of the leaf collecting and extruding device. Wheels 4 are fixed below the chassis 1.

[0042] The front end of the entrance of the described leaf collection extruding device is provided with suction head 5, leaves are sucked into extruding molding machine 4...

Embodiment 2

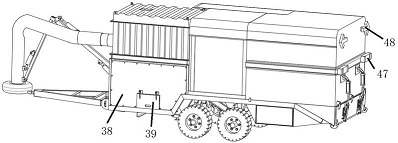

[0057] see Figure 12 , a kind of integrated equipment for walking leaf suction, sweeping and pressing rods, comprising a chassis 1, a suction device is provided on the chassis 1, a leaf collecting and extruding device is arranged below the suction device, and the leaf collecting and extruding device The device is connected with the rear cargo box 3 through the belt conveying system, the rear cargo box 3 is located at the rear end of the chassis 1, and a hydraulic device is fixed on the chassis 1, and the hydraulic device is connected with the operating device in the operating room 2. The operating room is located on the chassis 1 and is used to control the suction direction of the suction head of the leaf collecting and extruding device. Wheels 4 are fixed below the chassis 1 .

[0058] The front end of the entrance of the described leaf collection extruding device is provided with suction head 5, leaves are sucked into extruding molding machine 49 by suction device, is extru...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap