Prefabricated light air conditioner plate

A light-weight technology for air-conditioning panels, applied in buildings, building reinforcements, building components, etc., can solve problems such as affecting hoisting efficiency, lack of structural improvement, and increased weight of prefabricated air-conditioning panels, and achieve light panel weight and panel strength The effect of increasing and decreasing the amount of steel bars

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

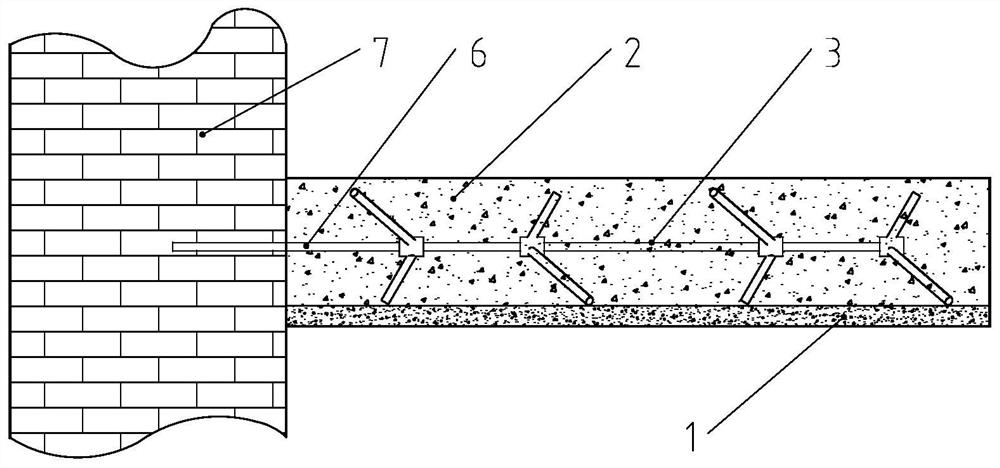

[0039] like figure 1 A prefabricated lightweight air-conditioning panel shown includes a bottom layer 1 , a pouring layer 2 and a skeleton 3 embedded in the pouring layer 2 .

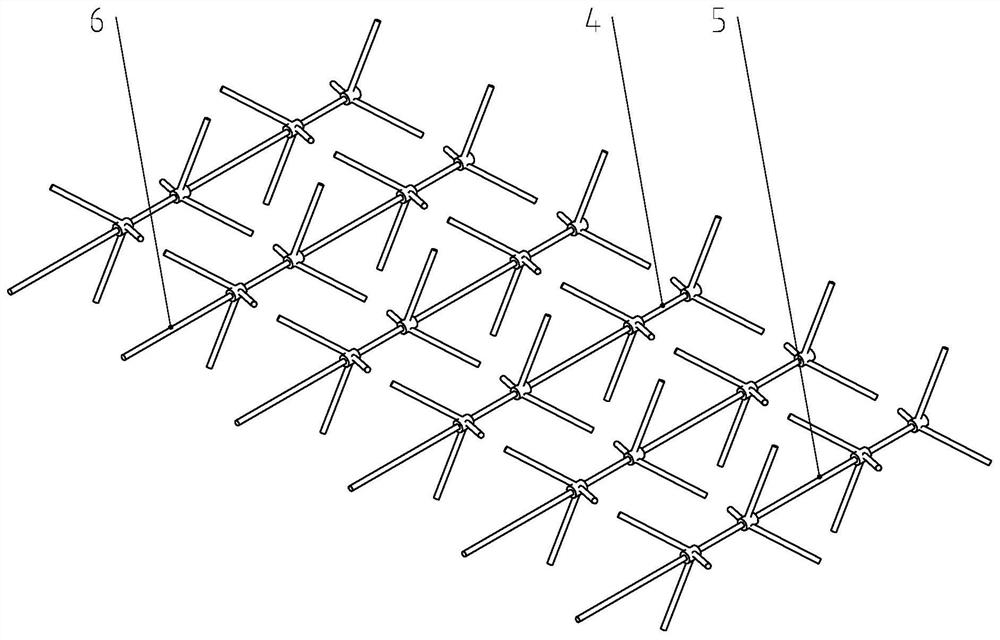

[0040] like figure 2 As shown, the skeleton 3 includes twelve branch units 4 , six connecting ribs 5 and six wall connecting ribs 6 .

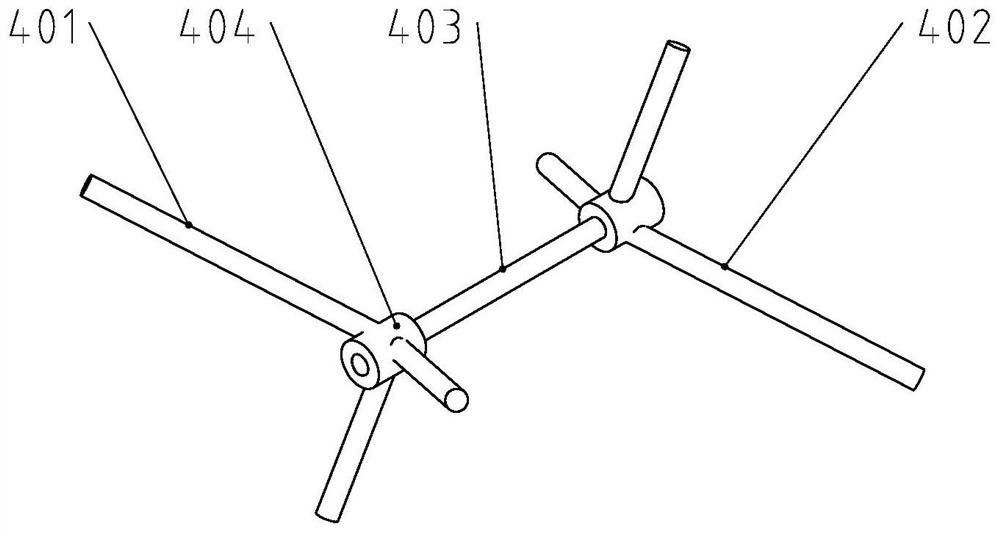

[0041] like image 3 and Figure 4 As shown, each branch unit 4 includes a left rib 401 , a right rib 402 , a transverse rib 403 and a node part 404 . The left rib 401 is radially connected to one end of the transverse rib 403 through the node part 404 , and the right rib 402 is radially connected to the other end of the transverse rib 403 through the node part 404 .

[0042] Both ends of the connecting rib 5 are respectively connected to the node parts 404 of the adjacent branch units 4 .

[0043] One end of the wall connecting rib 6 is embedded in the pouring layer 2 to fix the frame 3 , and the other end of the wall connecting rib 6 protrudes from the pouring l...

Embodiment 2

[0046] A kind of prefabricated lightweight air-conditioning panel, the technical scheme is identical with embodiment 1, and its difference is:

[0047] The distribution method of the branch units 4 is as follows: two identical branch units 4 connected by connecting ribs 5 are arranged vertically to form a branch unit group, and six groups of the aforementioned same branch unit groups are uniformly distributed side by side in the horizontal direction.

[0048] There are three ribs 401 on the left side and three ribs 402 on the right side. like Figure 5As shown, the projections of adjacent left ribs 401 on the side of the pouring layer 2 have an angle of 120°, and the projections of adjacent right ribs 402 on the side of the pouring layer 2 have an angle of 120°. The projections of the left rib 401 and the right rib 402 on the side of the pouring layer 2 are staggered, and the projections of the adjacent left rib 401 and right rib 402 on the side of the pouring layer 2 are sep...

Embodiment 3

[0057] A kind of prefabricated lightweight air-conditioning panel, the technical scheme is the same as embodiment 2, and its difference is:

[0058] like Figure 10 As shown, the skeleton 3 includes sixteen branch units 4 , eight connecting ribs 5 and eight wall connecting ribs 6 .

[0059] The distribution of the branch units 4 is as follows: each vertically arranges two identical branch units 4 connected by connecting ribs 5 to form a branch unit group, and eight groups of the aforementioned branch unit groups are evenly distributed side by side in the horizontal direction, adjacent to each other. The rotation angles of the tree branch unit groups along their own main axes are different. Specifically, if the rotation angle of the first group of tree branch unit groups along its own main axis is set to 0°, then the second group of tree branch unit groups adjacent to it will rotate along its own axis. The rotation angle of the main axis is 180°, the rotation angle of the thir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com