A kind of composite material of microporous plate, microporous plate, light bulletproof armor and manufacturing method thereof

A manufacturing method and technology of microporous plate, which are applied in the direction of armor, protective equipment, armor plate structure, etc., can solve the problems of poor bonding effect, easy debonding and dispersing, weak mechanical properties, etc., and achieve good application effect, The effect of reducing the weight of the armor and increasing the impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain and illustrate the present invention, and are not intended to limit the present invention.

[0035] The first embodiment of the present invention provides a composite material of a microporous plate, the composite material is made of ultra-high molecular weight polyethylene material modified by graphene, wherein graphene is modified by alkane chain grafting Graphene oxide, the graphene accounts for 0.5%-10% by mass of the ultra-high molecular weight polyethylene; the weight-average molecular weight of the ultra-high molecular weight polyethylene is 8.7×10 5 .

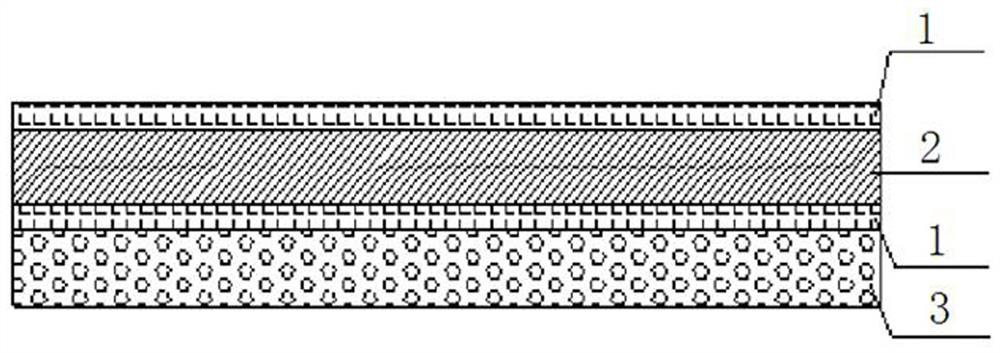

[0036] The second embodiment of the present invention proposes a microporous plate using the composite material of the first embodiment. The microporous plate is obtained by bonding 5 layers o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com