Patents

Literature

37results about How to "Multiple impact energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Disposable controlled completely-degradable plastic packing bag and preparation method thereof

The invention discloses a disposable controlled completely-degradable plastic packing bag, which is formed through melting, blending, extruding and film-blowing of components comprising in parts by weight: 20 to 45 parts of polyvinyl alcohol, 72 to 87 parts of starch, 10 to 20 parts of micromolecule plasticizer, 0.2 to 2 parts of modified inorganic nanometer additive, 0.1 to 1.5 parts of antioxidant, 0.5 to 3 parts of compatibilizer, 8 to 15 parts of inorganic filler, 0.1 to 1 part of ultraviolet absorber, and 0.1 to 1 part of pigment. The invention further discloses a preparation method of the plastic packing bag. The nanometer composite modifier in the packing bag adopts a micromolecule plasticizer easy to form a hydrogen bond with the starch, a certain amount of inorganic nanometer additives subject to surface treatment are added in the packing bag, so that after PVA (polyvinyl acetate) is modified by the nanometer composite modifier, the use amount of the molecule plasticizers is reduced greatly, the cost is lowed, the reduction of the mechanical property of a film is avoided, and the controlled completely-degradable film with excellent mechanical property and the use performance can be obtained.

Owner:NINGXIA GREEN BIODEGRADABLE PROD +1

Low-alloy bainite ductile iron abrading-ball

InactiveCN101200789AImprove impact resistancePromote formationFurnace typesHeat treatment furnacesChemical compositionHigh surface

A low alloy bainite ductile iron grinding ball is provided. The chemical compositions of the grinding ball (weight percentage) are as follows: 3.5 to 3.8 percent of C, 2.8 to 3.8 percent of Si, 0.1 to 0.5 percent of Mn, 0.15 to 0.35 percent of Cr, 0.35 to 0.5 percent of Mo, less than or equal to 0.03 percent of S, less than or equal to 0.1 percent of P, 0.03 to 0.08 percent of Mg, 0.5 to 1.5 percent of Cu, 0.01 to 0.03 percent of Bi and 0.02 to 0.07 percent of Re, and the rest is Fe. The ball is made through the following heat treatment steps: (1) heating the grinding ball to be at 880-960 DEG C; (2) quenching in mechanical oil; (3) taking the ball out when the surface temperature is 150-230 DEG C; (4) implementing the sands burying and the insulation tempering rapidly with temperature for 6-8h or taking the ball out for the air cooling after the sands burying and the insulation tempering for 1-3h. The obtained grinding ball has the advantages of reasonable organization structure, high surface strength, high hardness, good wear resistance, high inner toughness and perfect comprehensive property and is especially applied to crushing materials.

Owner:GUILIN UNIV OF ELECTRONIC TECH

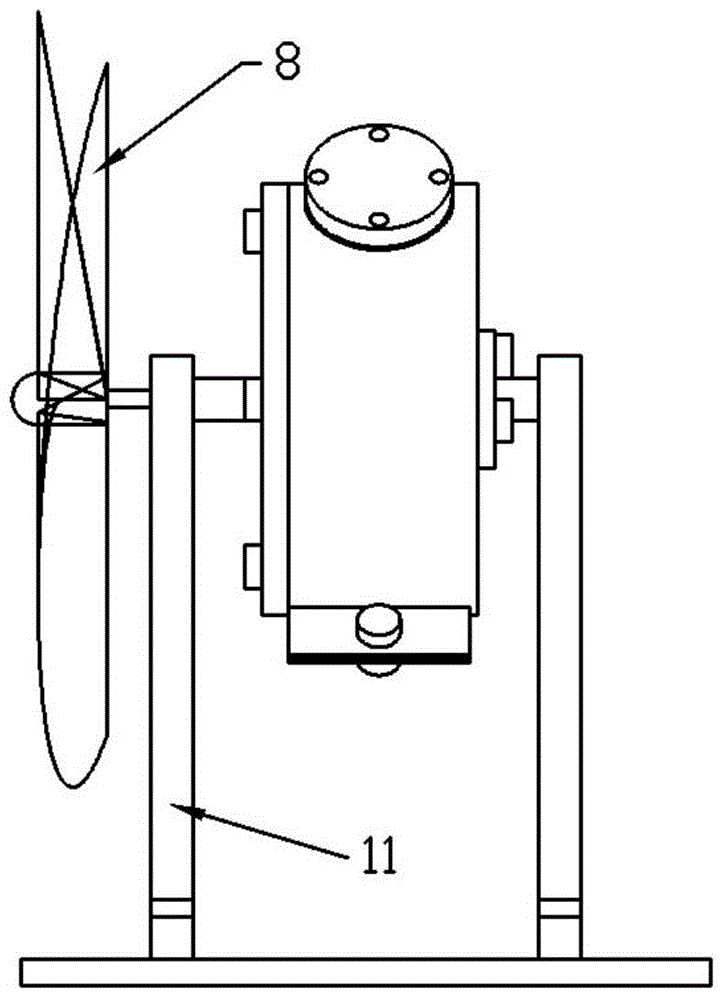

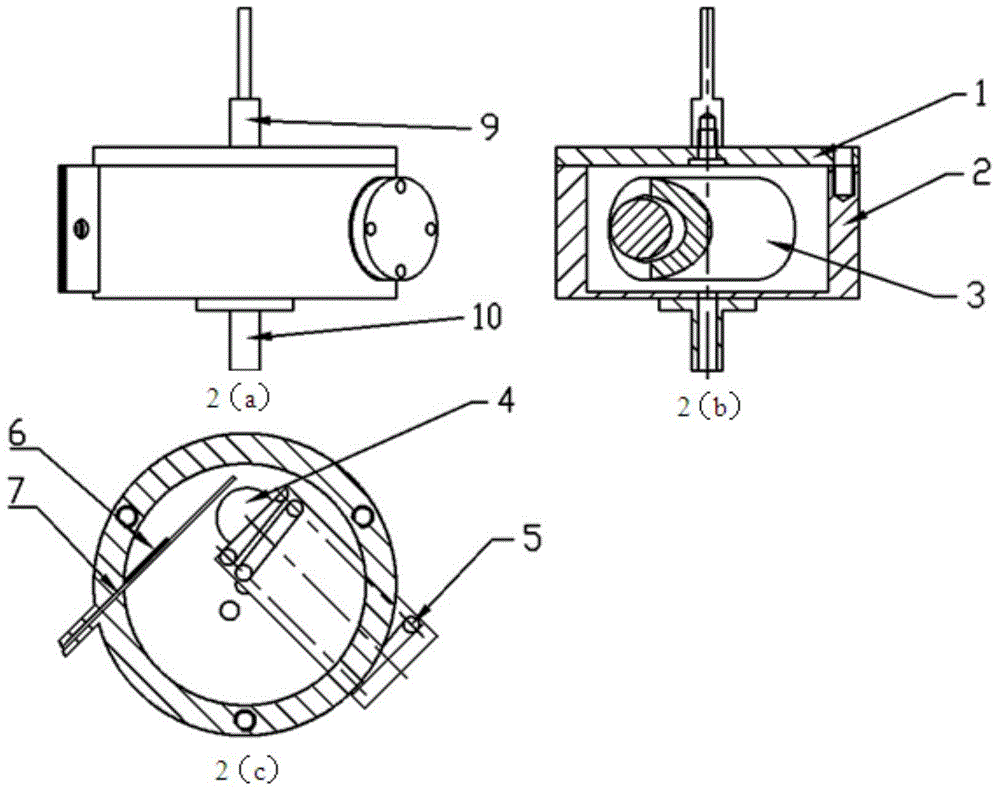

Piezoelectric power generation device and power generation method thereof

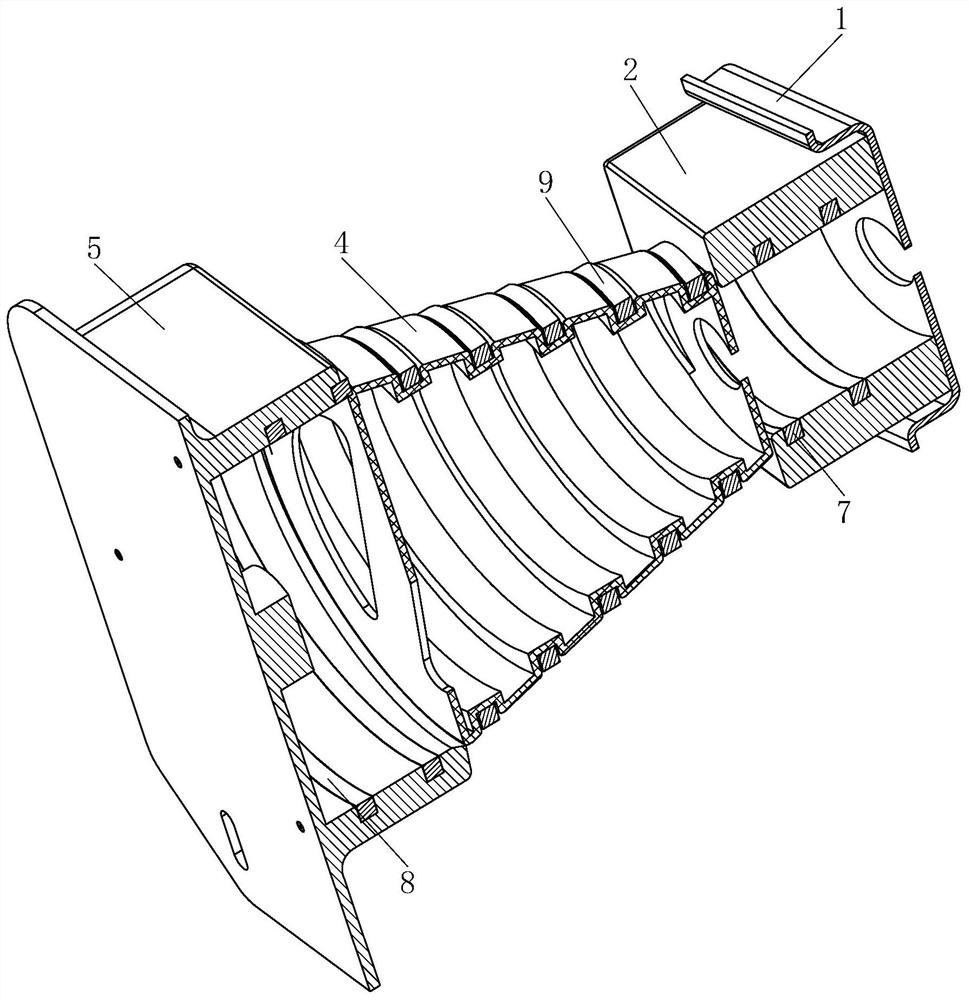

ActiveCN103956935ALarge amplitudeHigh energyPiezoelectric/electrostriction/magnetostriction machinesElectricityTurbine blade

The invention discloses a piezoelectric power generation device and a power generation method thereof, and belongs to the field of wind power generation and hydroelectric generation. The piezoelectric power generation device comprises a turbine rotor assembly, a spring ball assembly and a piezoelectric vibrator assembly, wherein the turbine rotor assembly comprises a box cover, a box body, a left shaft, a right shaft, a turbine blade and a main shaft frame, the left shaft and the right shaft are fixedly connected with the box cover and the box body respectively, the turbine blade is fixed to the left end of the left shaft, and the left shaft and the right shaft are arranged on the main shaft frame; the spring ball assembly comprises an installation cylinder, a spring and an elastic ball, the installation cylinder is installed on the box body, one end of the spring is fixedly arranged in the installation cylinder, the other end of the spring is in a free state, the elastic ball is arranged at the end, in the free state, of the spring, the end, extending into the box body, of the installation cylinder is open, the end, outside of the box body, of the installation cylinder is sealed, and the end, in the free state, of the spring is located at the open end of the installation cylinder; the piezoelectric vibrator assembly comprises an elastic piece and a piezoelectric material attached to the elastic piece in an adhesive mode, one end of the elastic piece is embedded in the outer cylindrical face of the box body, the other end of the elastic piece is free, and the elastic piece makes contact with the elastic piece after moving in the axis direction of the installation cylinder.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

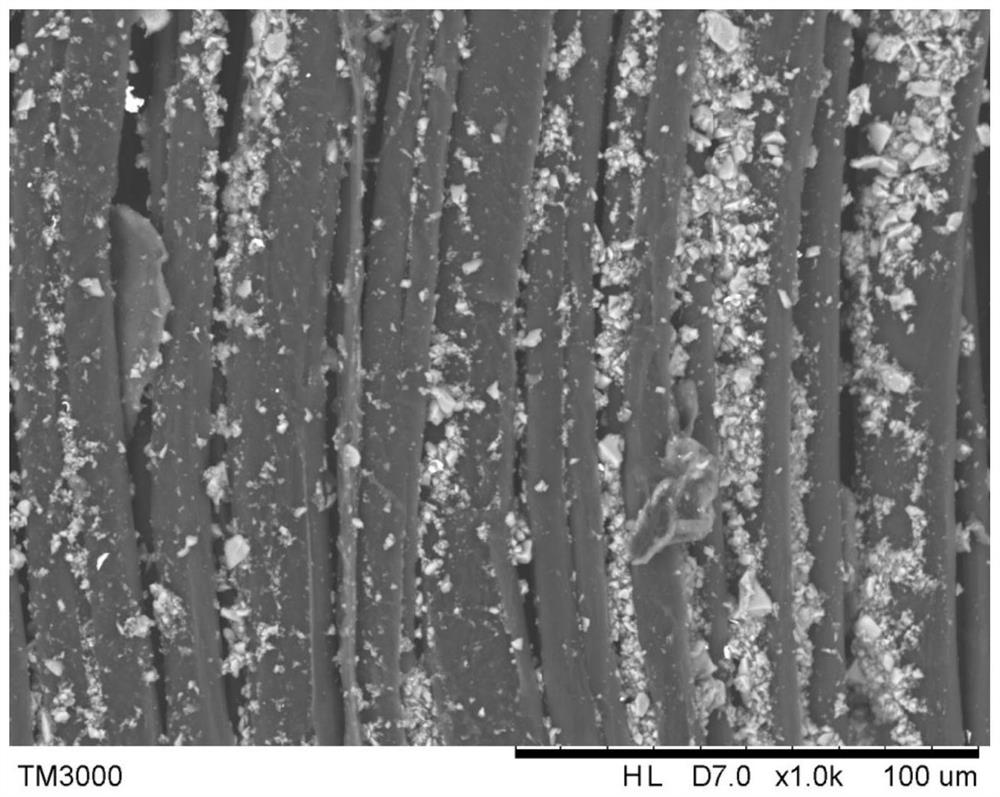

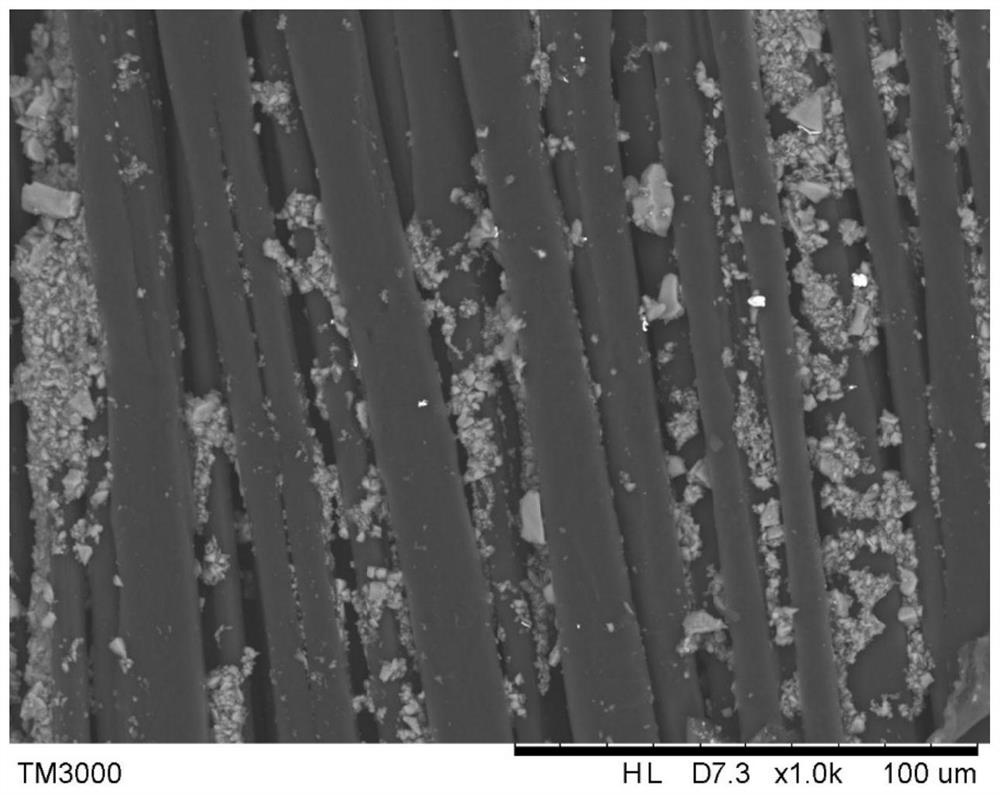

Flexible protective composite material and manufacturing method thereof

InactiveCN112900105AWith bulletproof and sharp edgeIncreased interfacial shear strengthDry-cleaning apparatus for textilesUltrasonic/sonic fibre treatmentUHMWPE polyethylenePlasma treatment

The invention relates to the technical field of composite materials, and particularly discloses a flexible protective composite material. The flexible protective composite material is obtained by adopting an ultra-high molecular weight polyethylene fabric subjected to plasma treatment as a matrix and uniformly adhering a shear thickening liquid to the matrix. According to the flexible protective composite material provided by the invention, the ultra-high molecular weight polyethylene fabric is treated with the plasma treatment technology, so that the surface performance of the ultra-high molecular weight polyethylene fabric can be effectively improved, the adhesive force and the bonding performance of a dispersion in the shear thickening liquid on the surface of the ultra-high molecular weight polyethylene fabric are improved, and under the condition that the layer number and the weight of the ultra-high molecular weight polyethylene fabric are not increased, the protection performance and the flexibility of the protective composite material are effectively improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Preparing method for high-tenacity low-alloy wear-resistant steel for bucket tooth

ActiveCN105838987AImprove organizationImprove performanceProcess efficiency improvementRare-earth elementSteelmaking

The invention discloses a preparing method for high-tenacity low-alloy wear-resistant steel for a bucket tooth. The high-tenacity low-alloy wear-resistant steel comprises, by mass percent, 0.35%-0.45% of C, 1.20%-1.60% of Si, 1.00%-1.40% of Mn, 0.70%-0.90% of Cr, 0.15%-0.25% of Mo, 0.40%-0.60% of Cu, 0.05%-0.10% of Re, 0%-0.025% of P and 0%-0.025% of S. The preparing method comprises the steps that smelting is conducted, an alloy is smelted through an acid induction furnace, metal furnace burdens include steelmaking pig iron, steel scraps, ferromolybdenum and copper and are smelted to form molten steel, then, silicon iron, ferromanganese, ferrochromium and rare earth elements are added in a pouring ladle, and the smelted molten iron is poured in the pouring ladle to be poured; cooling is conducted, box opening is conducted for shakeout, and air cooling is conducted; thermal treatment is conducted, and a casting is subjected to austenitizing; quenching is conducted; carbon partition is conducted in a salt bath furnace; and the casting is placed in an insulating furnace to be subjected to bainite isothermal transformation, and finally the casting is taken out to be subjected to air cooling. The low-alloy wear-resistant steel composed of the above components and obtained through the smelting and thermal treatment technology is fine in internal grain structure, high in surface hardness, good in abrasion resistance, low in cost and capable of being widely applied to bucket tooth manufacturing.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Low-alloy bainite ductile iron oil quenching isothermal tempering heat treatment process

A low alloy bainite ductile iron oil quenching with temperature isothermal tempering heat treatment process includes: (1) heating a ductile iron work piece to be at 880 to 960 DEG C for the austenization; (2) quenching the work piece in machine oil; (3) taking out the ductile iron work piece when the surface temperature is 150 to 230 DEG C; (4) keeping the ductile iron work piece with temperature and rapidly burying sands for the heat preservation and the tempering for 6 to 8 hours; or burying sands for the heat preservation and the tempering for 1 to 3 hours and then taking the work piece out for the air cooling. Through refractory bricks and molding sands in an insulation packet or a ground pit, the process forms a reasonable temperature gradient from the inside of the ductile iron to the surface, a sands layer, the insulation packet or the ground pit. The slow and stable cooling speed which accords with the requirement is established. The isothermal tempering temperature is effectively controlled. The residue heat after the heat treatment on the ductile iron work piece is used to realize the isothermal transformation from austenite to bainite, which is more beneficial to the formation of bainite tissues. The obtained ductile iron work piece tissues have the advantages of reasonable structure and perfect comprehensive property and are especially applied to gears, crankshafts, grinding balls, etc.

Owner:GUILIN UNIV OF ELECTRONIC TECH

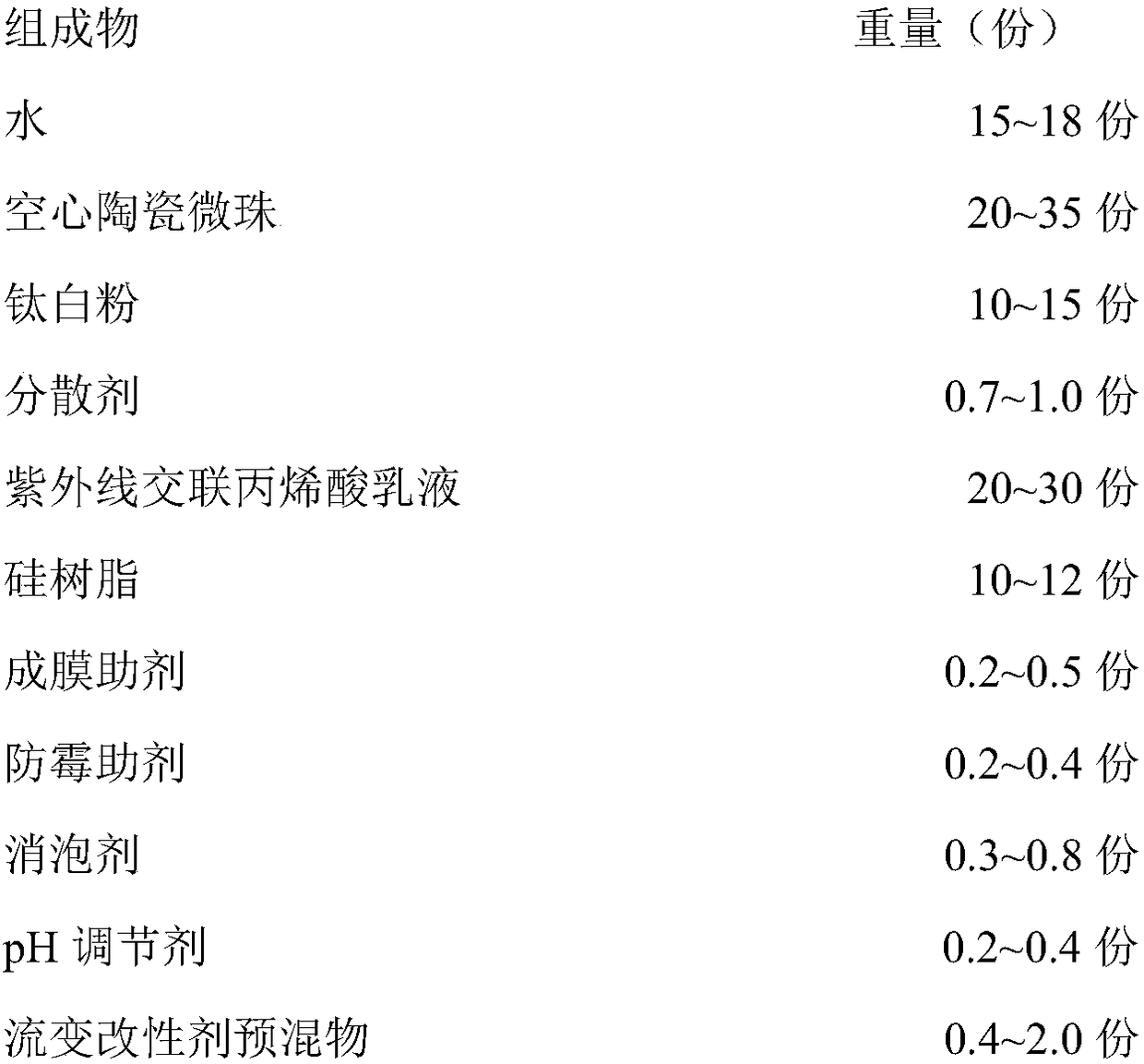

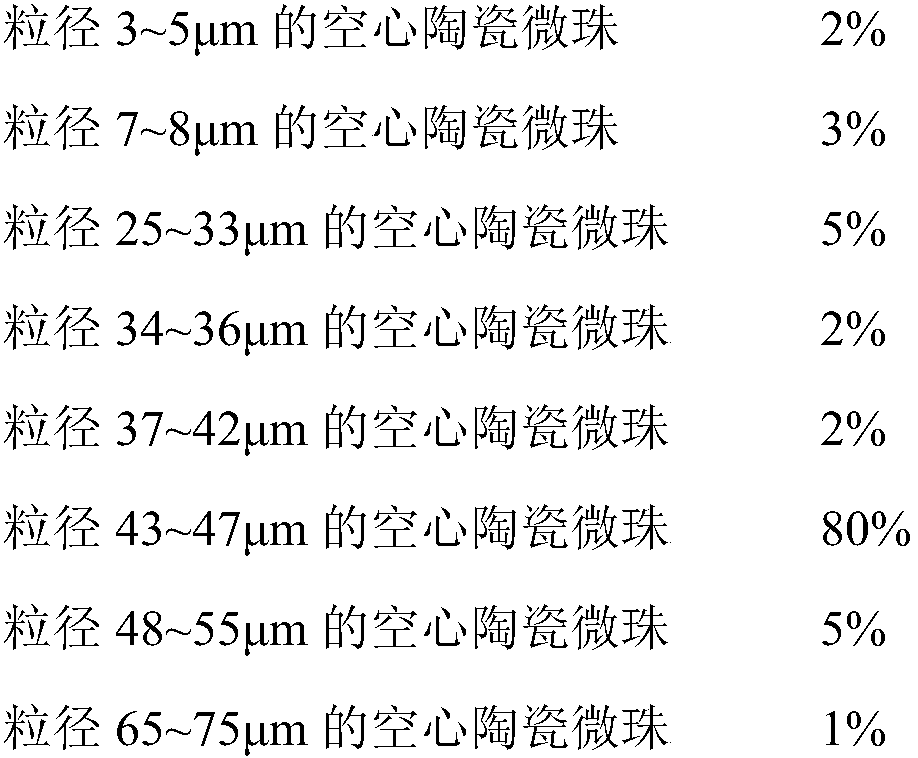

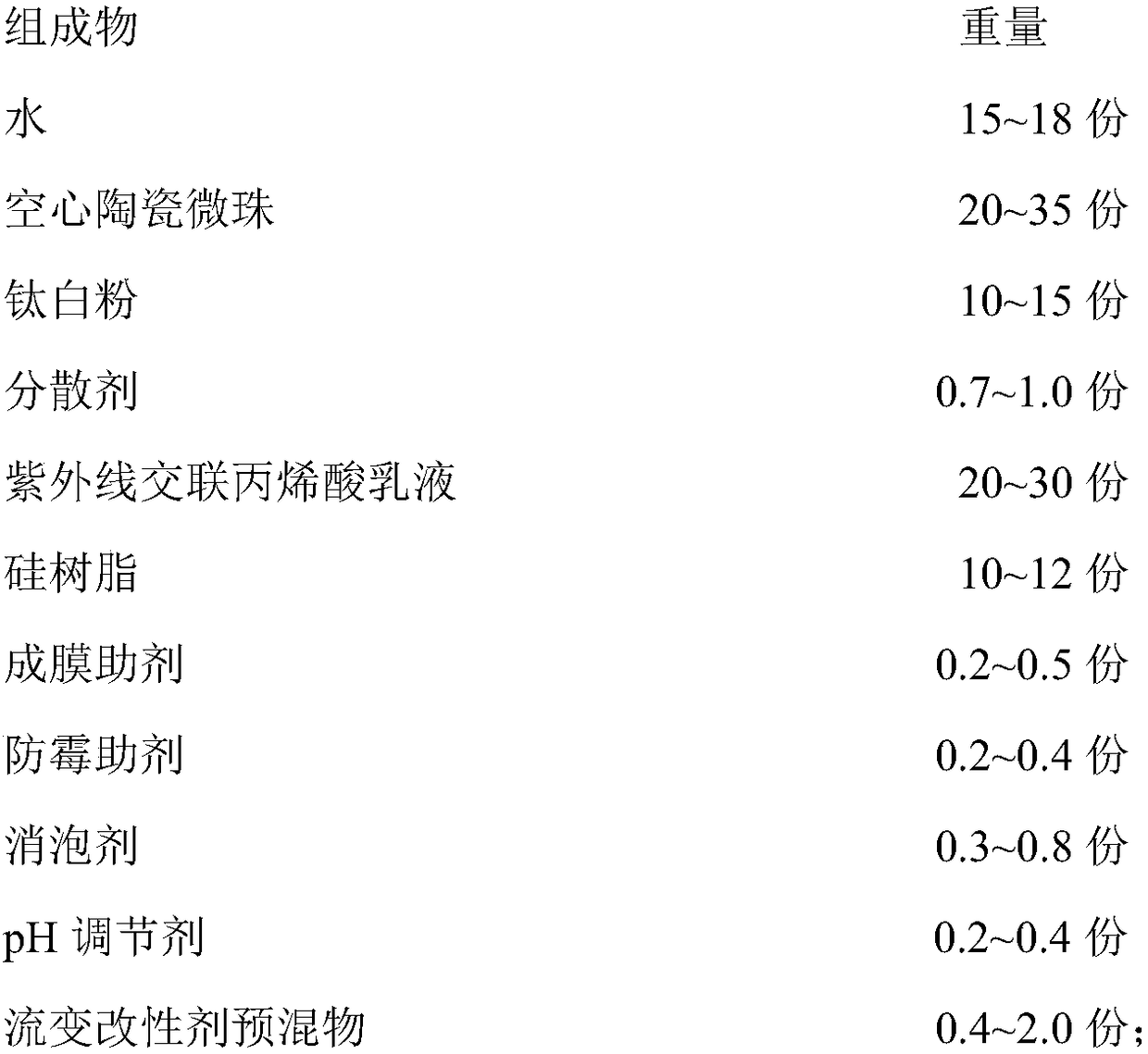

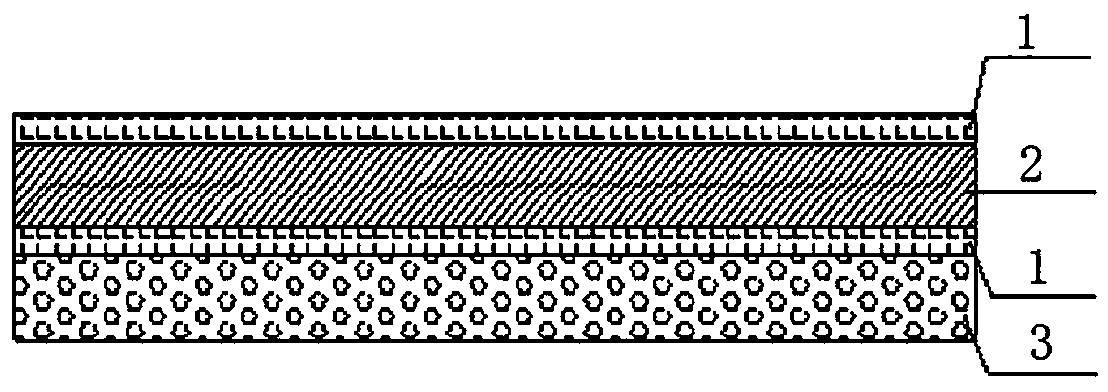

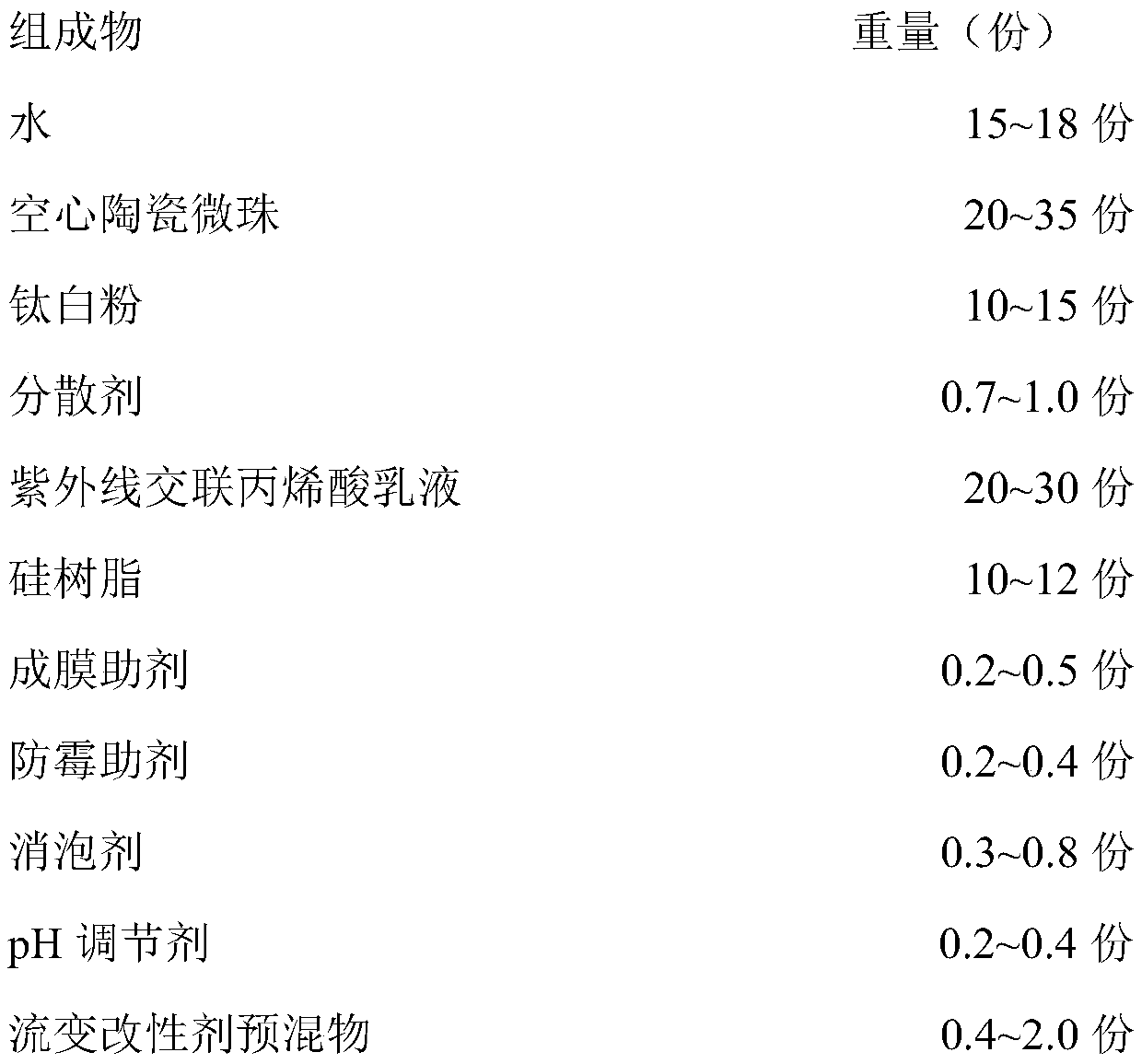

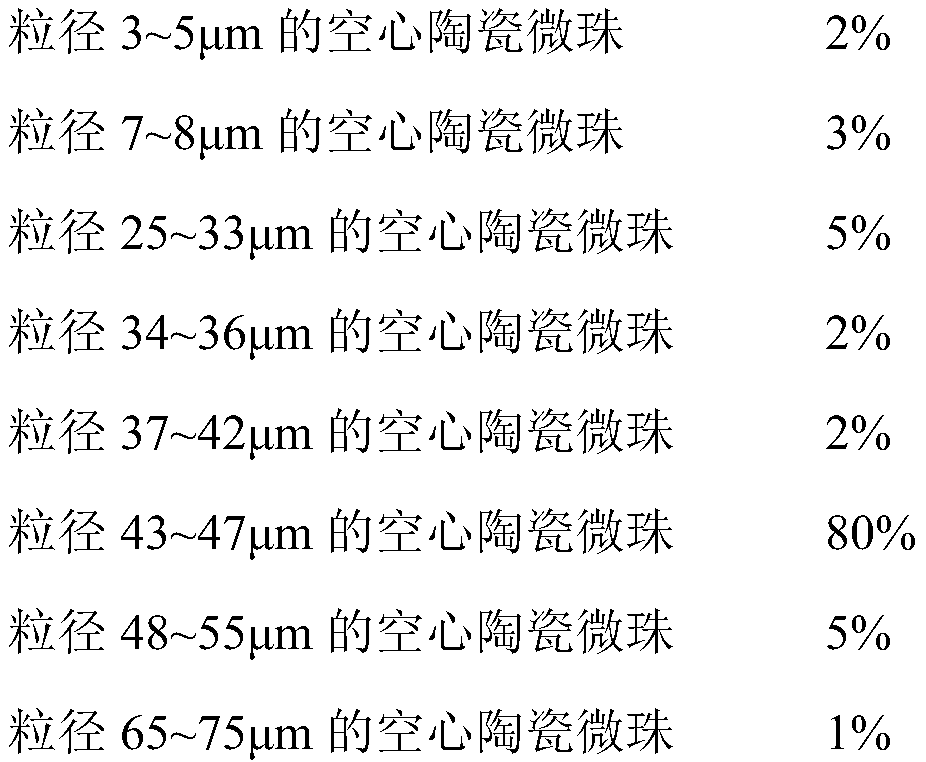

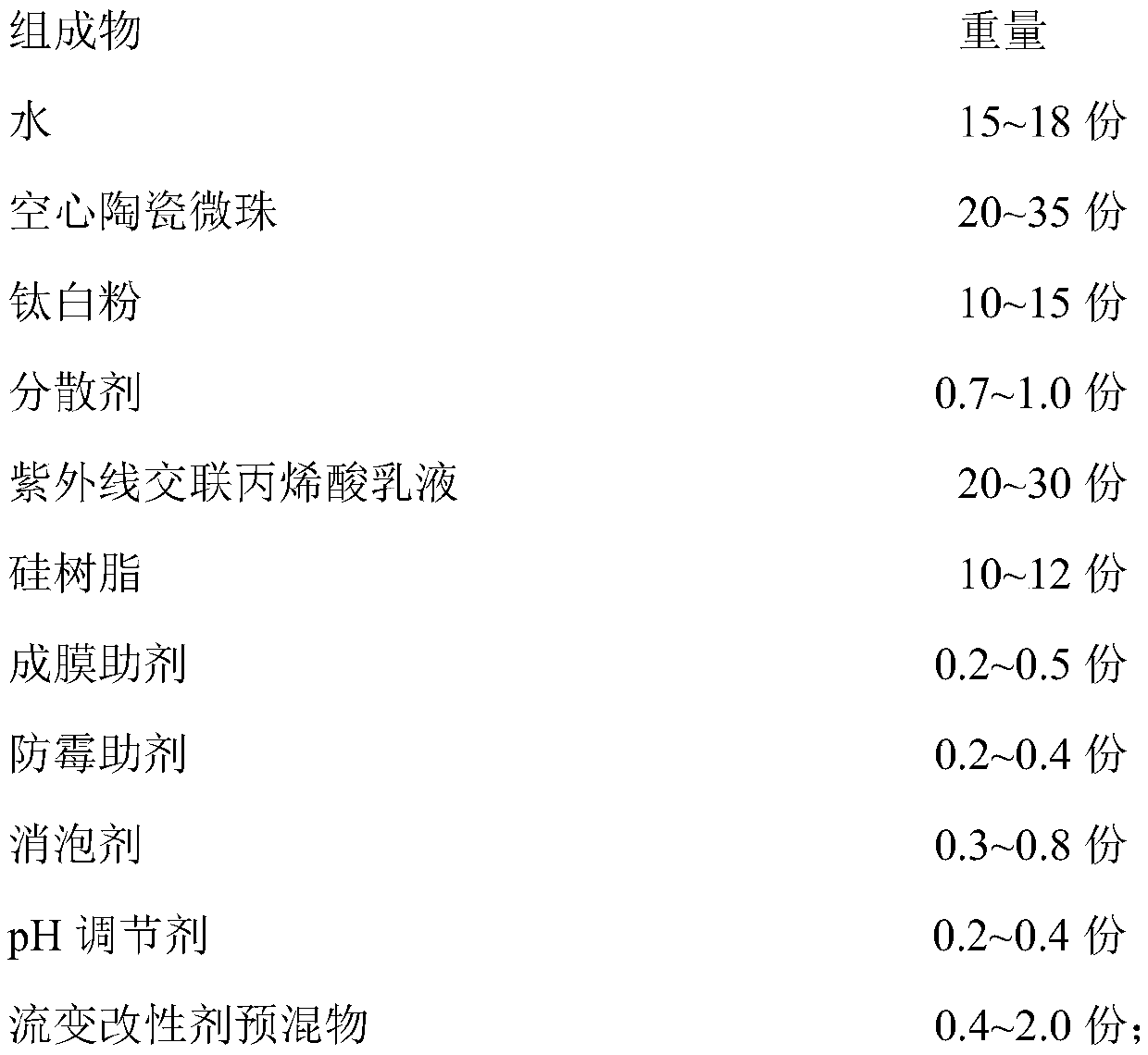

Ultrahigh-viscosity and high-sunlight-reflection-ratio waterproof and heat insulation coating and preparation method thereof

ActiveCN108059891AReduce the ratioIncreased hemispherical emissivityAntifouling/underwater paintsPaints with biocidesLow speedMicrosphere

The invention provides ultrahigh-viscosity and high-sunlight-reflection-ratio waterproof and heat insulation coating and a preparation method thereof and relates to a waterproof and heat insulation coating and a preparation method thereof. The ultrahigh-viscosity and high-sunlight-reflection-ratio waterproof and heat insulation coating is prepared from water, hollow ceramic microspheres, titaniumwhite powder, a dispersant, ultraviolet crosslinking acrylic emulsion, silicon resin, a film forming auxiliary agent, a mildew-proof auxiliary agent, a de-foaming agent, a pH (Potential of Hydrogen) regulator and a rheological modifier premix. The method comprises the following steps: adding raw materials into a reaction kettle and stirring the raw materials while adding to obtain a mixture; regulating the pH value and adding the rheological modifier premix; mixing a liquid phase at a low speed; decompressing and distilling to remove water, so as to obtain the coating. According to the ultrahigh-viscosity and high-sunlight-reflection-ratio waterproof and heat insulation coating provided by the invention, the coverage capability of the coating is greatly improved so that the minimum thickness for covering a substrate is reduced and reaches 0.5 to 0.8mm. The sunlight reflection ratio of the coating can reach 0.92 under the thickness. The preparation method is used for preparing the high-performance waterproof and heat insulation coating.

Owner:哈尔滨拓百世环保涂料有限公司

Composite material of microporous plates, microporous plates, lightweight bulletproof armor and manufacturing method thereof

ActiveCN110220418AHigh impact strengthGood compatibilityProtective equipmentSynthetic resin layered productsMicro perforated plateElastomer

The invention discloses a composite material of microporous plates, the microporous plates, a lightweight bulletproof armor and a manufacturing method thereof. The composite material is prepared froma graphene modified ultra-high molecular weight polyethylene material, the microporous plates are made of the composite material, and micropores are formed in the microporous plates; the bulletproof armor comprises an elastomer layer, a ceramic layer and a microporous plate layer, wherein the elastomer layer is made of elastomer resin, and the thickness of the resin layer is 1-15mm, the ceramic layer is made of bulletproof ceramic, and the bulletproof ceramic is one-layer or multi-layer; and the microporous plate layer is the microporous plate, the microporous plates are single-layer or multi-layer, and layers of the multi-layer microporous plates are bonded with each other through adhesives. The elastomer layer of the armor is applied to the ceramic layer in a spraying mode and is connected with the microporous plate layer in a cementing mode. The composite material of the microporous plates, the microporous plates, the lightweight bulletproof armor and the manufacturing method thereof have the beneficial effects that the protection capability is improved, the weight is reduced, and the application effect is good.

Owner:JIANGXI HONGDU AVIATION IND GRP

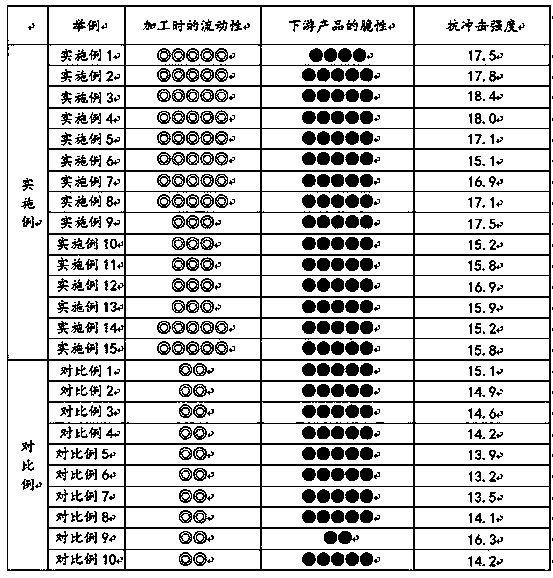

PVC easy-to-process opaque high-impact MBS and preparation method thereof

InactiveCN109971086AHigh impact strengthImprove impact resistanceButyl acrylateTransition temperature

The invention discloses a PVC easy-to-process opaque high-impact MBS and a preparation method thereof, and relates to the technical field of PVC auxiliary agent production and preparation. The PVC easy-to-process opaque high impact MBS is a core-nuclear-shell three-layer structure, and the PVC easy-to-process opaque high impact MBS comprises the following components in percent by mass: 1-20% of acore layer structure, 70-85% of a nuclear layer structure, and 5-20% of a shell layer structure; the core layer structure is a semi-rigid light cross-linking copolymer of a styrene monomer and an acrylate monomer, and the ratio of the styrene monomer to the acrylate monomer is 95 / 5-5 / 95; the core layer structure is a relatively soft light cross-linking butadiene styrene polymer with relatively lowglass transition temperature, and the ratio of butadiene and styrene is 100 / 0-80 / 20; and the shell layer structure is a copolymer with relatively high glass transition temperature of styrene, butyl acrylate and methyl methacrylate, and the mass percentages of styrene, butyl acrylate and methyl methacrylate are respectively 0.2-5%, 0.2-2% and 13-20%. Problems of low impact strength, poor processing fluidity and the like of existing MBS products for opaque PVC products are solved.

Owner:SHANDONG DONGLIN NEW MATERIALS CO LTD

Preparation method of nano titanium dioxide modified polyacrylate coating agent with core-shell structure

The invention relates to a preparation method of a nano titanium dioxide modified polyacrylate coating agent with a core-shell structure. Firstly, an aluminum zirconium coupling agent and nano titanium dioxide are added to deionized water, and the mixture is stirred for a refluxing reaction for 30 min; deionized water, an emulsifier, an acrylate monomer and a nano titanium dioxide dispersion liquid are added to a reaction kettle, and the mixture is heated to 55-58 DEG C and stirred at a high speed to form an emulsified liquid; deionized water, the acrylate monomer and an emulsifier are added to an emulsification kettle and stirred at a high speed to form a pre-emulsified liquid; an initiator is dissolved in deionized water, and an initiator solution is prepared; after the temperature of the reaction kettle is increased to 65-68 DEG C, the initiator solution is added, and a thermal insulation reaction is performed for 1 h; the pre-emulsified liquid, crosslinking monomers and the remaining initiator water solution are dropwise added within 2 h, the mixture is subjected to a thermal insulation reaction at the temperature of 80 DEG C for 1 h after the pre-emulsified liquid, crosslinking monomers and the remaining initiator water solution are dropwise added, and cooling and filtration are performed.

Owner:绍兴博凯科技信息咨询有限公司

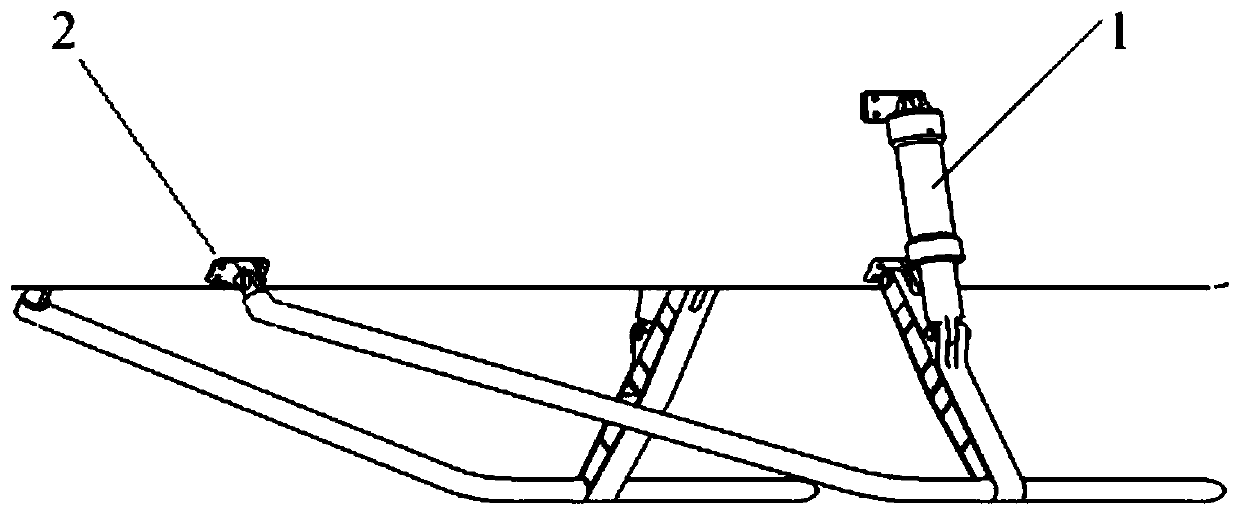

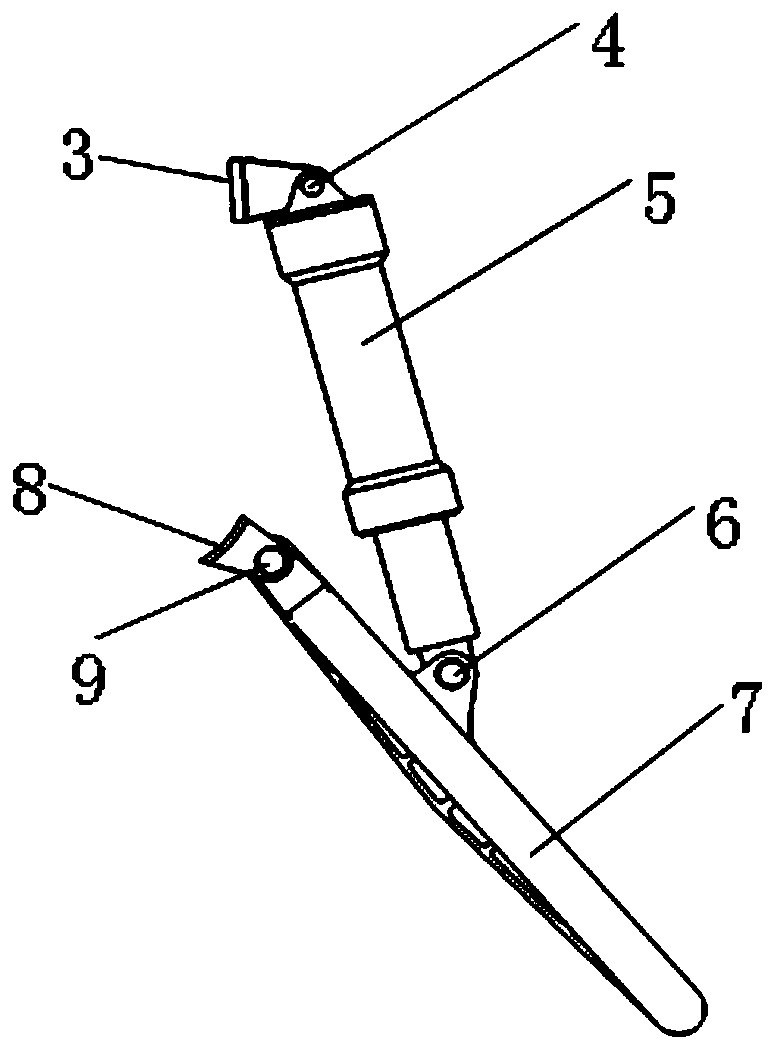

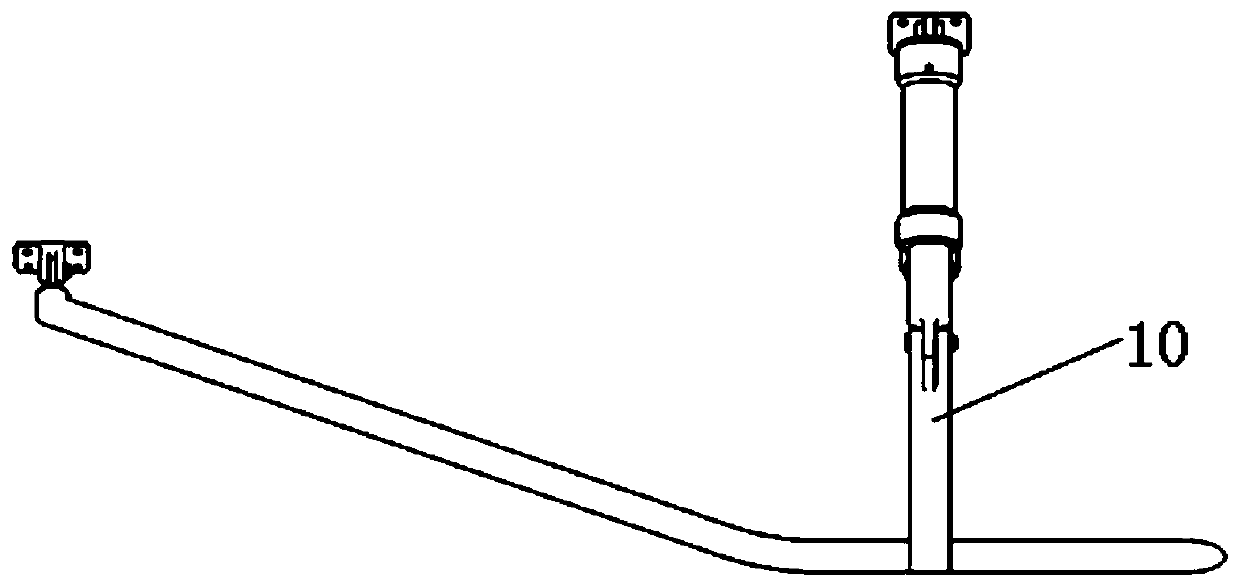

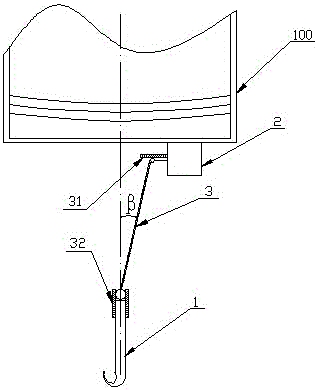

Rocker arm type unmanned aerial vehicle ski buffering device

InactiveCN109795678AHigh weather environment adaptabilityIncrease buffer strokeSkis/runnersFriction forceFuselage

The invention discloses a rocker arm type unmanned aerial vehicle ski buffering device. The rocker arm type unmanned aerial vehicle ski buffering device is composed an upper vehicle body connector, adamper, a ski bar and a rocker arm, wherein the upper vehicle body connector is arranged under a vehicle body and connected with the upper end of the damper through a damper-vehicle body connecting pin; a ski bar front connector is arranged in front of the vehicle body and connected with the ski bar through a ski bar-vehicle body connecting pin; the lower end of the damper is connected with the rocker arm through a damper-rocker arm connecting pin. During parachute landing, when the ski bar touches down, a ski bar support arm module can rotate around the ski bar front connector and a rocker arm-vehicle body connector under the action of support reaction force of the ground; during rotation, the ski bar support module can compress the damper, which then absorbs the sinking kinetic energy ofthe vehicle body to achieve buffering and damping effects; the ski is in a rocker arm type structure to achieve a long buffer stroke and reduce recovery overloading, and by means of high sideslip andground fiction, can absorb more impact energy to effectively protect safety of the vehicle body and equipment.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

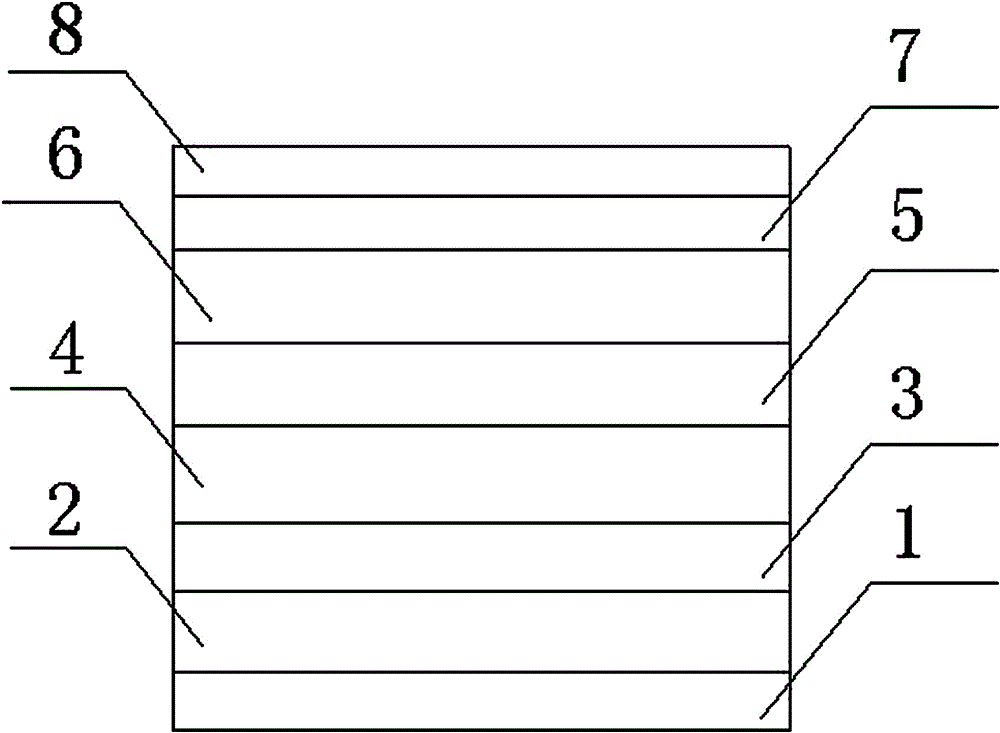

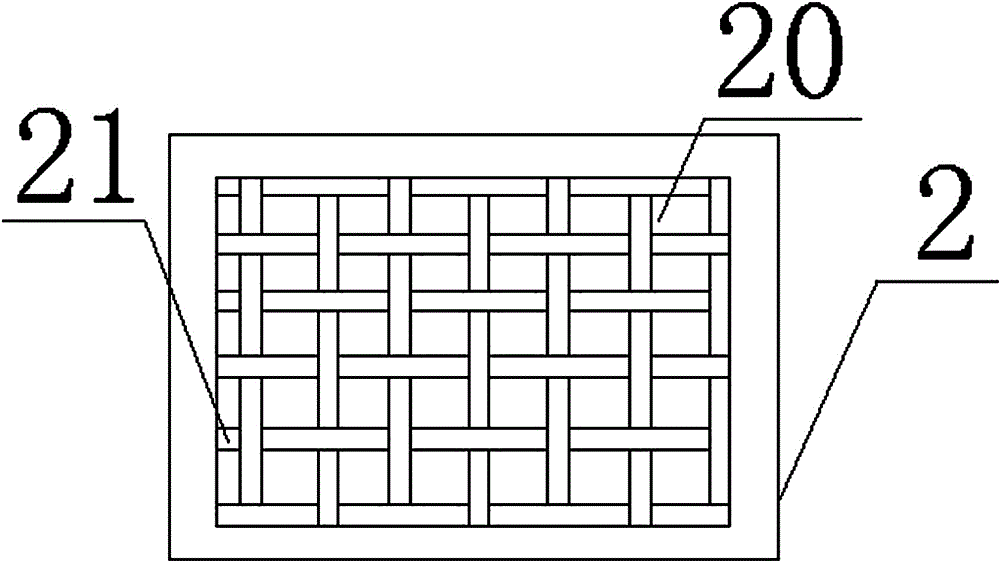

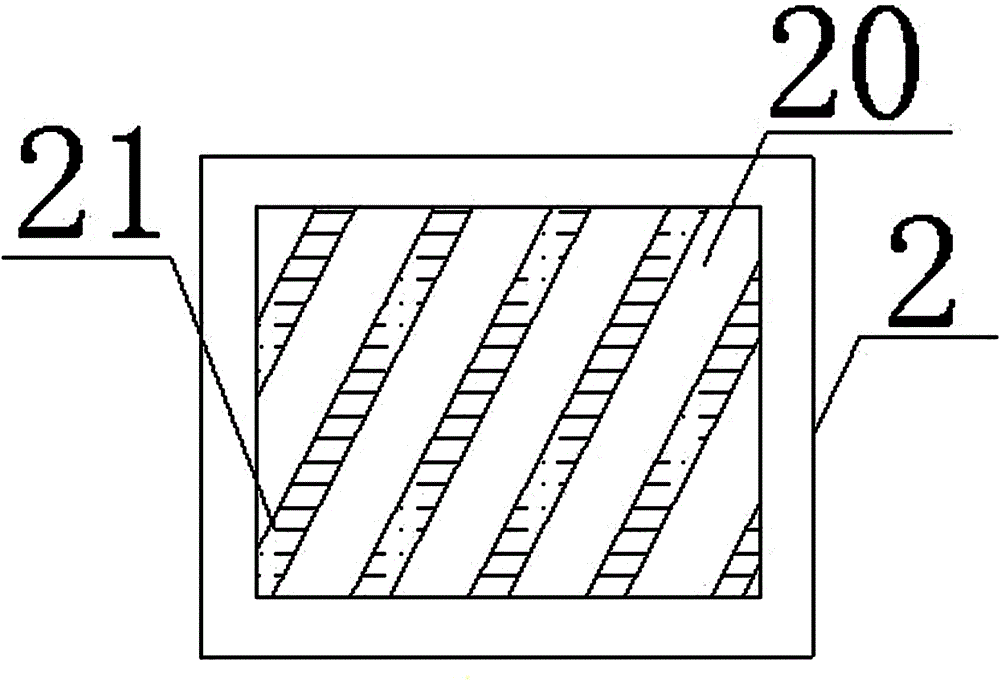

Elastic fireproof wallboard

ActiveCN106049786ALarge specific surface areaIncrease the areaCovering/liningsCeramicwareInsulation layerEngineering

The invention discloses an elastic fireproof wallboard which comprises a base layer, a frame layer, an adhesive layer, a plastering mortar layer, an insulation layer, a latex layer, a decorative coating and an abrasion-resistant layer. The base layer is covered by the frame layer. The frame layer is composed of a plurality of workpieces which are arranged in parallel or in a staggered mode and form filling cavities. The filling cavities are filled with filler. The frame layer is covered by the adhesive layer. The adhesive layer is covered by the plastering mortar layer. The plastering mortar layer is covered by the insulation layer. The insulation layer is covered by the latex layer. The upper surface of the latex layer is coated with the decorative coating made of decorative paint. The upper surface of the decorative coating is coated with the abrasion-resistant layer made of transparent abrasion-resistant paint.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

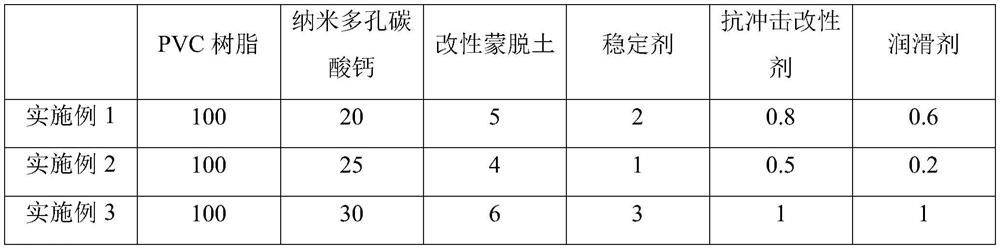

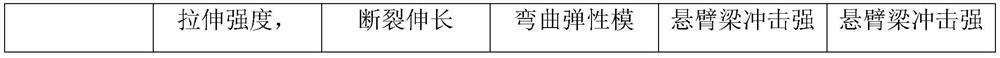

High-rigidity PVC electric conduit and preparation method thereof

The invention relates to the technical field of electric power pipes, and particularly discloses a high-rigidity PVC electric power conduit and a preparation method thereof. The high-rigidity PVC electric conduit is prepared from the following raw materials in parts by weight: 100 parts of PVC resin, 20-30 parts of nano-porous calcium carbonate, 4-6 parts of modified montmorillonite, 1-3 parts of a stabilizer, 0.5-1 part of an anti-impact modifier and 0.2-1 part of a lubricant, the modified montmorillonite is prepared by performing intercalation treatment on montmorillonite by using a cationic modifier and polyvinylpyrrolidone. The power conduit can be used for cable protection, and has the advantages of high rigidity and high toughness.

Owner:广东中讯通讯设备实业有限公司

Magnesia carbon brick and preparation method thereof

The invention relates to the technical field of refractory materials, in particular to a magnesia carbon brick and a preparation method thereof. The refractory material comprises 55-110 parts of fusedmagnesite, 12-16 parts of graphite, 1-3 parts of a binding agent and 1-6 parts of an additive, wherein the binding agent is modified phenolic resin; through the design of the magnesia-carbon brick, the technical problem that the performance of the magnesia-carbon brick is reduced due to the fact that phenolic resin is used as a binding agent, the high temperature resistance is poor and the magnesia-carbon brick is easy to oxidize in the prior art is solved.

Owner:北京利尔高温材料股份有限公司

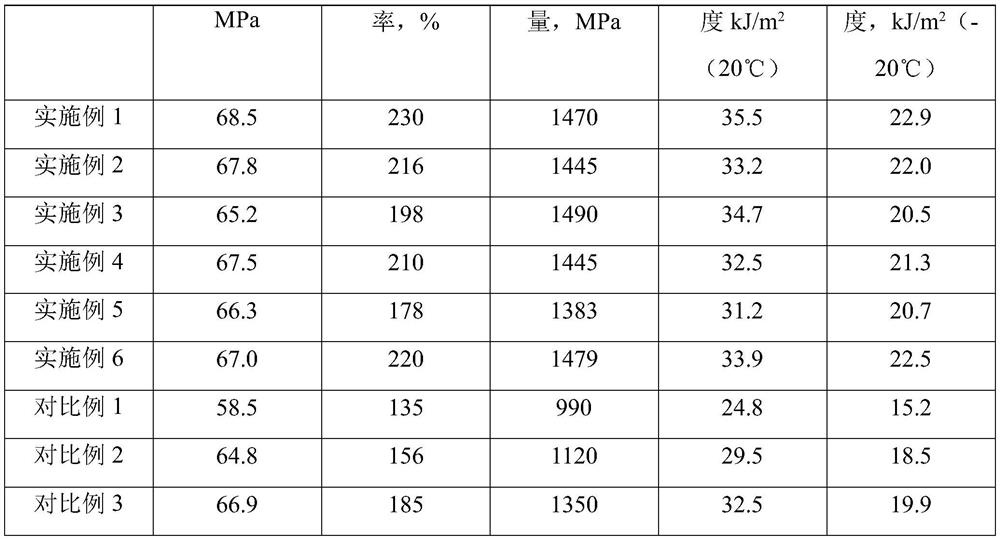

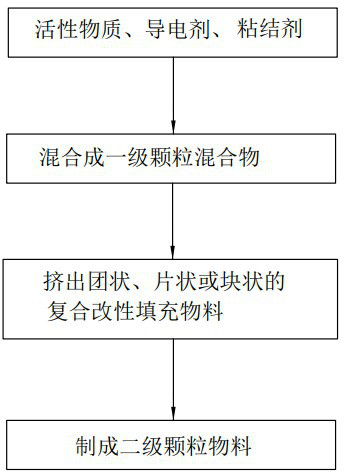

Filling granulation method used for extrusion molding

PendingCN113119337AImprove liquidityImprove uniformityHybrid capacitor electrodesSecondary cellsPhysical chemistryPolymer chemistry

The invention discloses a filling granulation method used for extrusion molding. The filling granulation method comprises the following steps that firstly, 70-99% of a powder active material, 0-10% of a powder conductive agent and 1-20% of a powder binder are selected and added into a mixer for mixing to obtain a primary particle mixture; the primary particle mixture is added into a double-screw extruder, an open mill or an internal mixer to obtain a sheet-shaped, ball-shaped or block-shaped composite modified filling material; and finally, the composite modified filling material is added into a granulator for granulation treatment to obtain a secondary granular material. According to the filling granulation method, the secondary particle material with an average particle size of 100 microns-5 mm and a spherical, ellipsoidal, worm-shaped or irregular shape is obtained by adopting a mixing or extruding technology, the fluidity and uniformity of the material are improved, the material blocking phenomenon is avoided, the problems of holes and wave rolls of an electrode film are avoided, the thickness and surface density are uniform and controllable, and the quality of the electrode film in an extrusion molding mode is improved.

Owner:GMCC ELECTRONICS TECH WUXI CO LTD

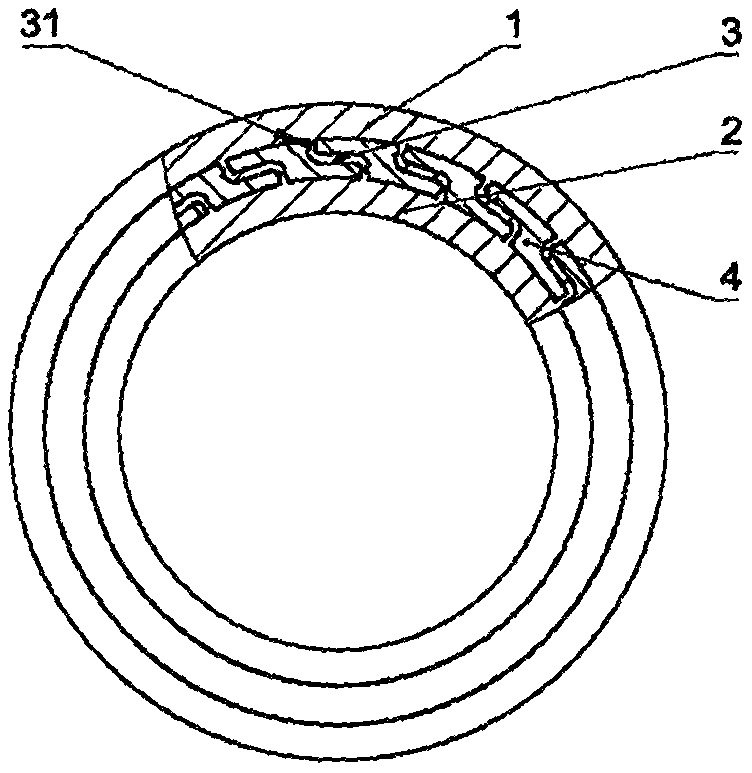

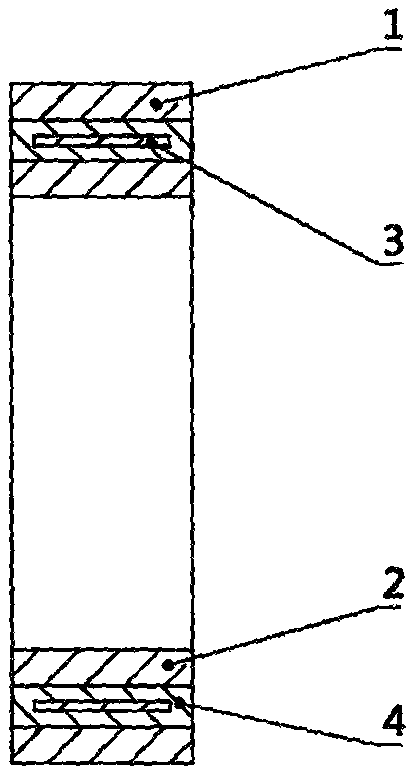

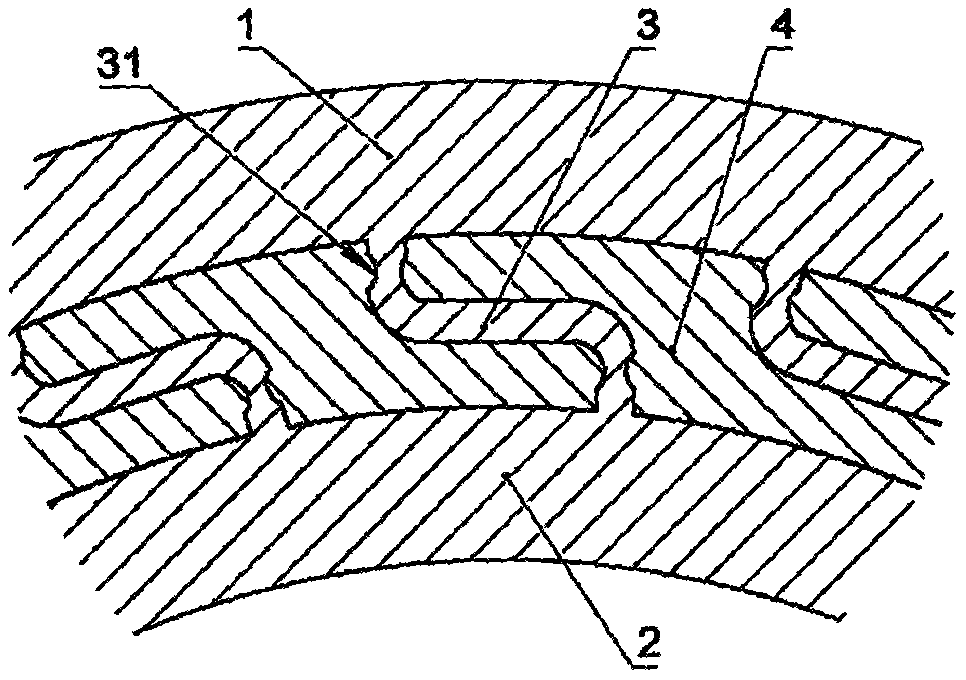

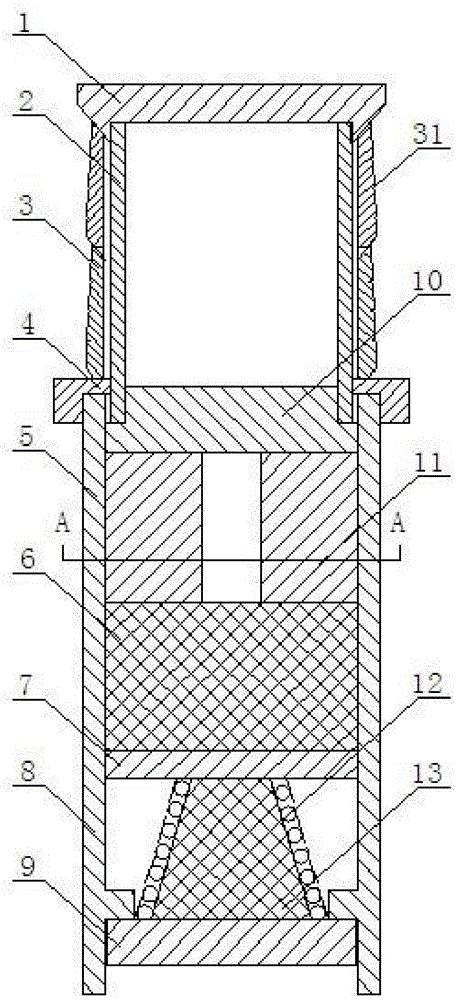

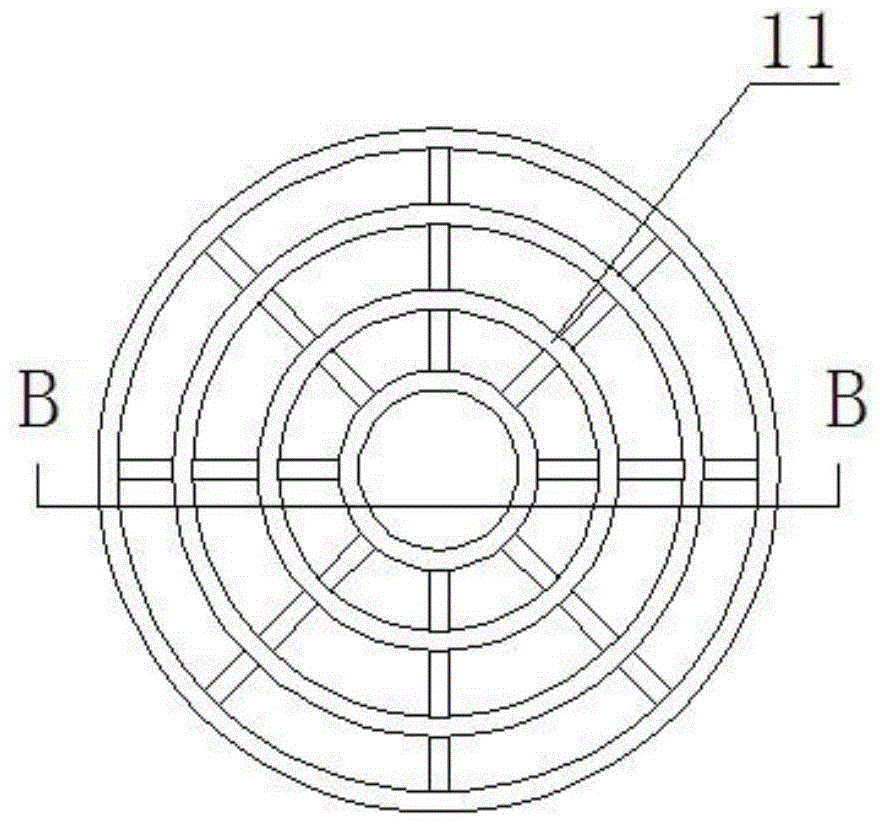

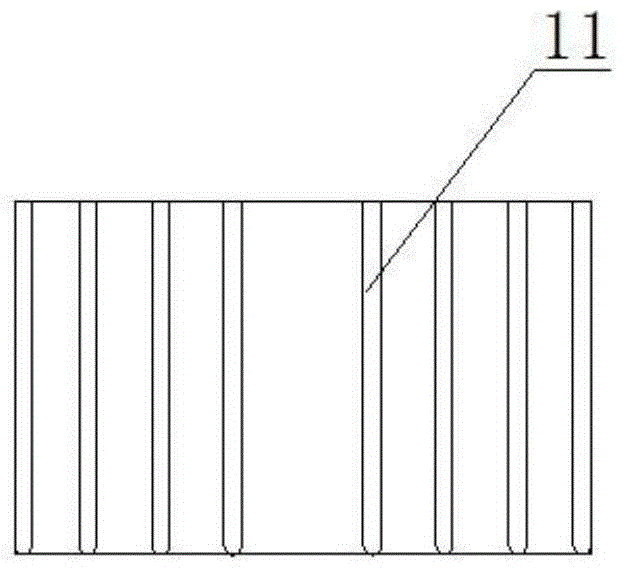

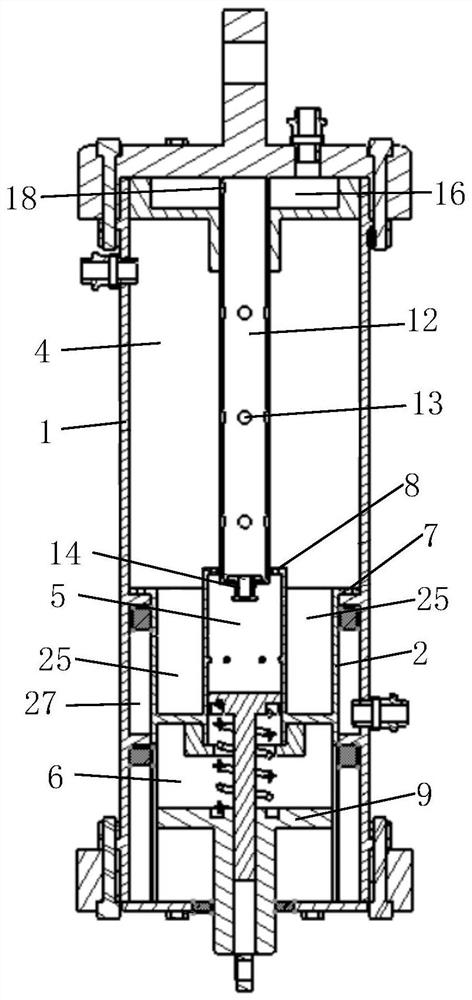

Magnetic suspension rotor falling radial protection device

PendingCN112460154AImprove protectionMultiple impact energyBearing assemblyBearingsRolling-element bearingStructural engineering

The invention discloses a magnetic suspension rotor falling radial protection device. The magnetic suspension rotor falling radial protection device is composed of a protection ring outer ring, a protection ring inner ring, Z-shaped flexible hinges and damping materials, the protection ring outer ring and the protection ring inner ring are connected through the multiple Z-shaped flexible hinges which are evenly distributed in the circumferential direction, and other gaps between the inner ring and the outer ring are filled with the damping materials. The relative positions of the protection ring outer ring and the protection ring inner ring are coaxial, the structural size of the protection ring outer ring is determined according to the shape and size of a bearing hole cooperating with theprotection ring outer ring, and the structural size of the protection ring inner ring can be determined according to the size of a bearing outer ring or a bearing inner hole cooperating with the protection ring inner ring. The magnetic suspension rotor falling radial protection device can cooperate with a rolling bearing to form a magnetic suspension rotor protection device capable of circumferentially rotating, and can directly cooperate and be assembled with an inner ring or an outer ring of the rolling bearing to form a structural form that a protection ring is fixed or the protection ringcan rotate.

Owner:北京亚之捷动力科技有限公司

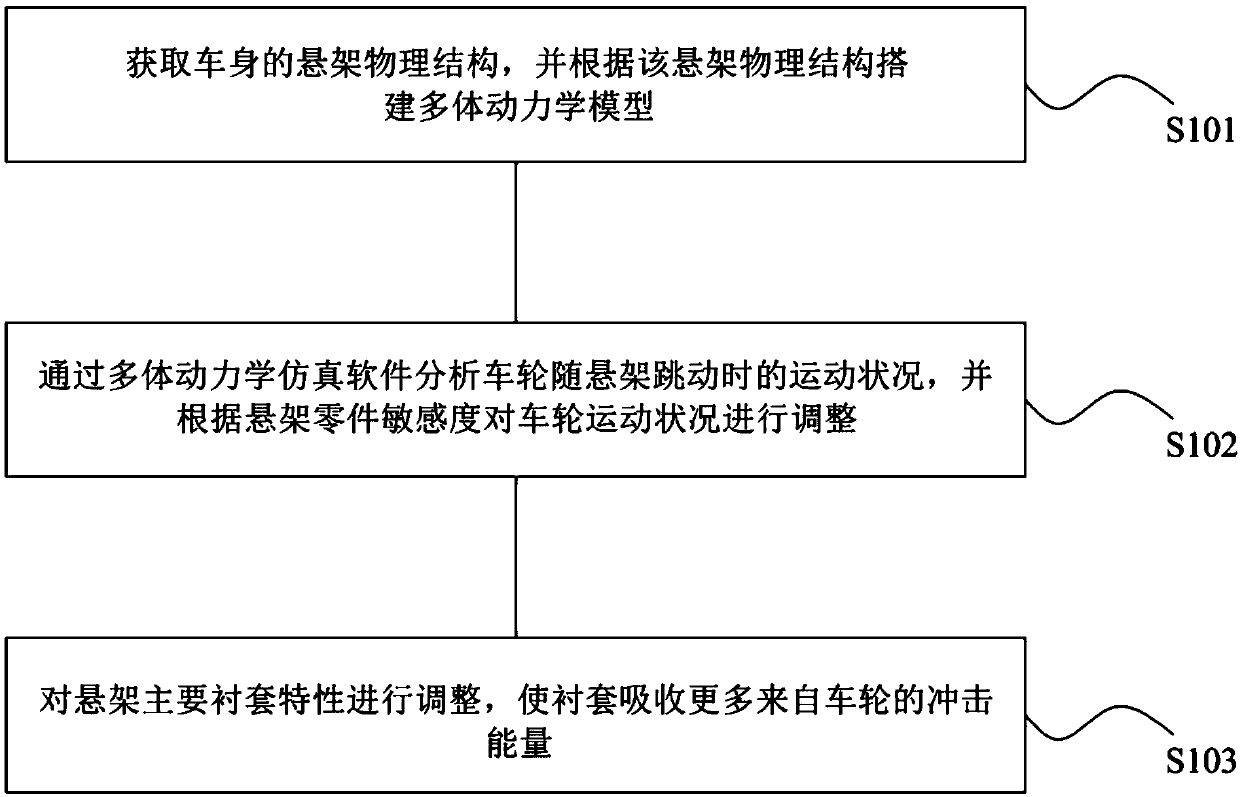

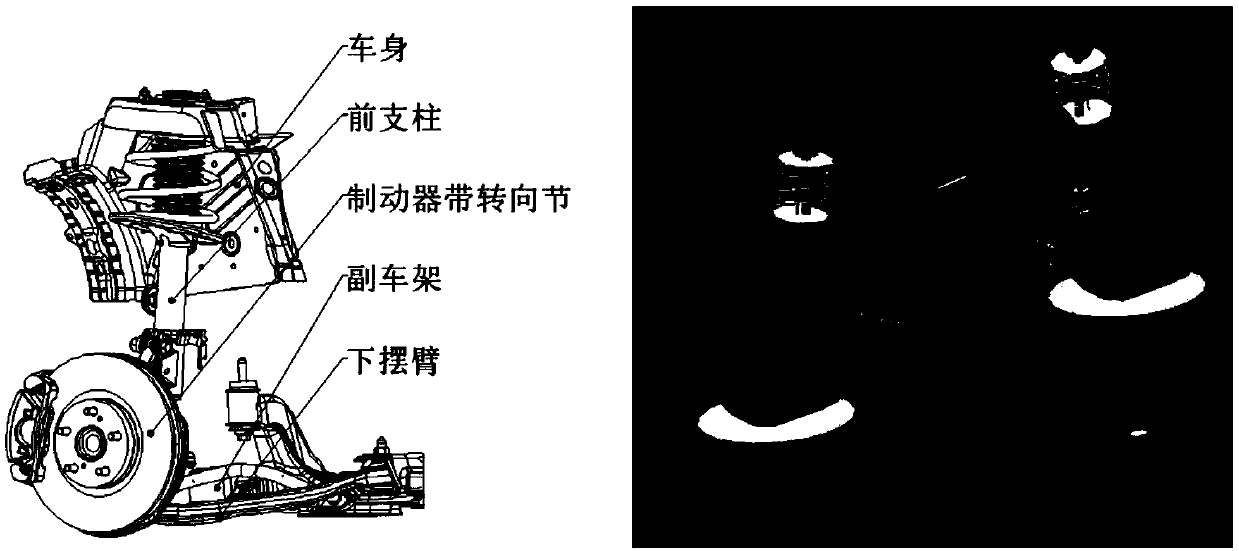

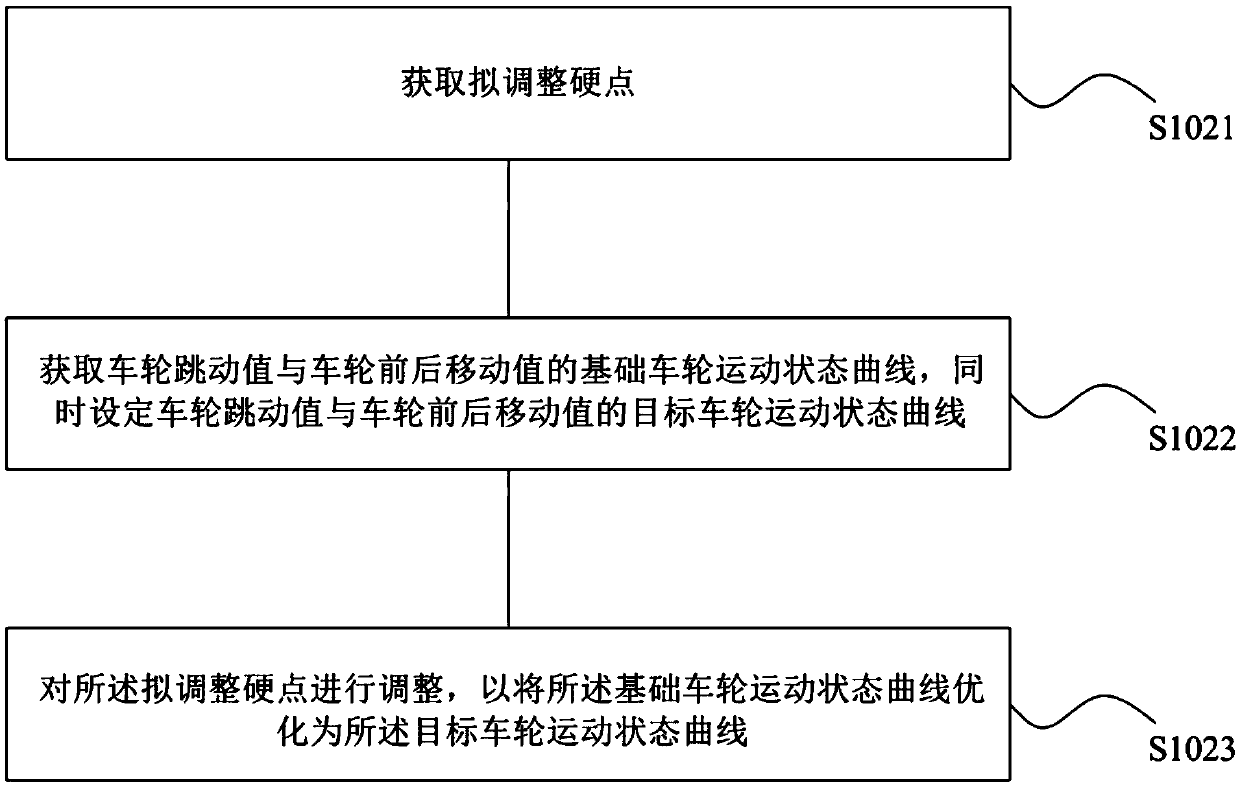

Vehicle body structure optimization method and system

InactiveCN109684705AImprove ride comfortImprove versatilityGeometric CADDesign optimisation/simulationAutomotive engineeringDynamic simulation

The invention discloses a vehicle body structure optimization method and system, and the method comprises the steps: obtaining a suspension physical structure of a vehicle body, and building a multi-body dynamics model according to the suspension physical structure; Analyzing the movement condition of the wheel along with the suspension frame through multi-body dynamics simulation software, and adjusting the movement condition of the wheel according to the sensitivity of a suspension frame part; The main bushing characteristics of the suspension are adjusted, so that the bushing absorbs more impact energy from the wheel. According to the method, the motion characteristics of the suspension mechanism can be determined through multi-body kinematics analysis in the design stage; The bushing structure is redesigned according to the vehicle parameter information, the existing suspension structure can be used to a great extent in the chassis development process, the universality of parts isimproved, the chassis development and optimization cost is effectively reduced, and the vehicle performance can be greatly improved.

Owner:JIANGLING HLDG

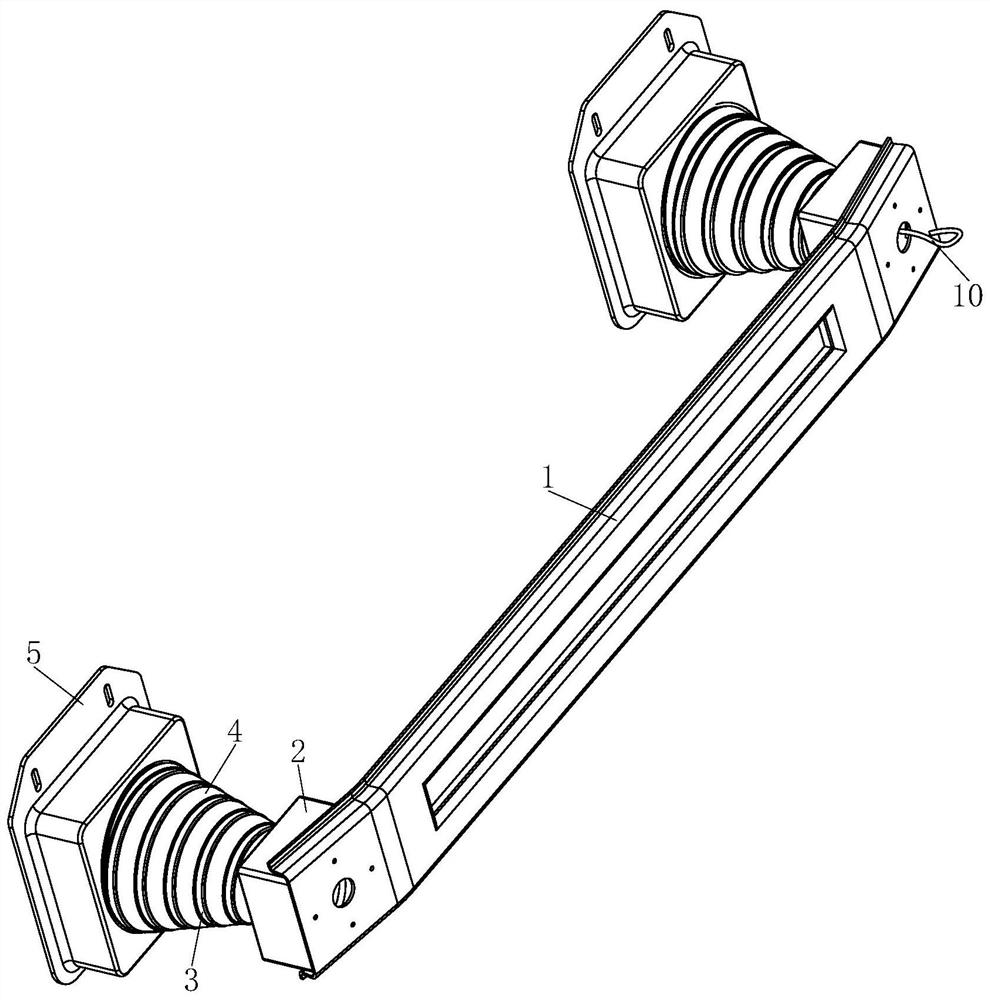

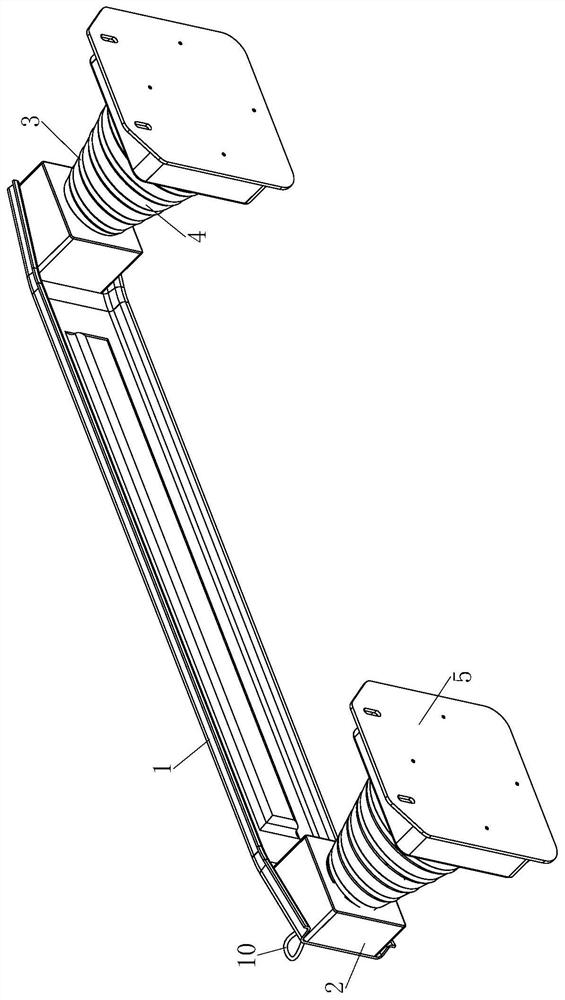

Bumper based on spring energy absorption and buffering

The invention belongs to the technical field of automobile parts, and particularly relates to a bumper based on spring energy absorption buffering. The bumper comprises a cross beam, a connecting block, an elastic piece, a supporting piece and a fixing piece; when the cross beam is impacted, impact force is transmitted to the connecting piece and then transmitted to the elastic piece, then the elastic piece is compressed, impact energy is absorbed through deformation of the elastic piece, due to the elasticity characteristic of the elastic piece, the shape of the elastic piece is easily changed in the whole anti-collision beam structure, therefore, the impact energy can be absorbed by the elastic piece firstly, the energy is prevented from being transmitted to other parts, damage to the other parts is prevented, the driving safety is improved, and the maintenance cost after collision is reduced; and meanwhile, through the arranged supporting piece, the stability of the cross beam and the elastic piece is kept under the normal condition, then the cross beam is prevented from shaking in the driving process, the stability of the cross beam is improved, and then the stability of the vehicle structure is improved.

Owner:卞强

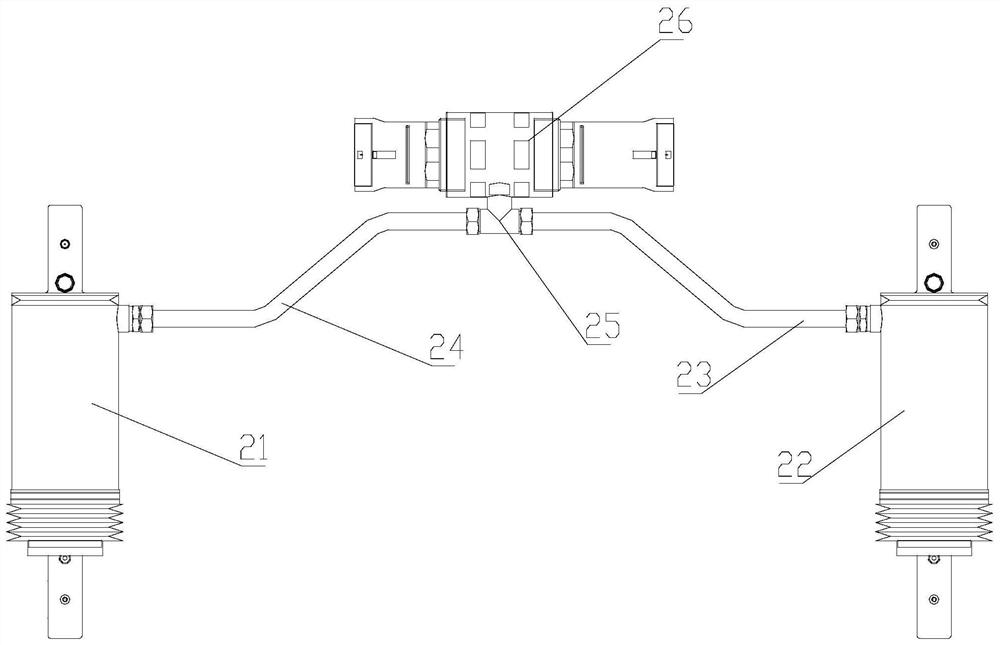

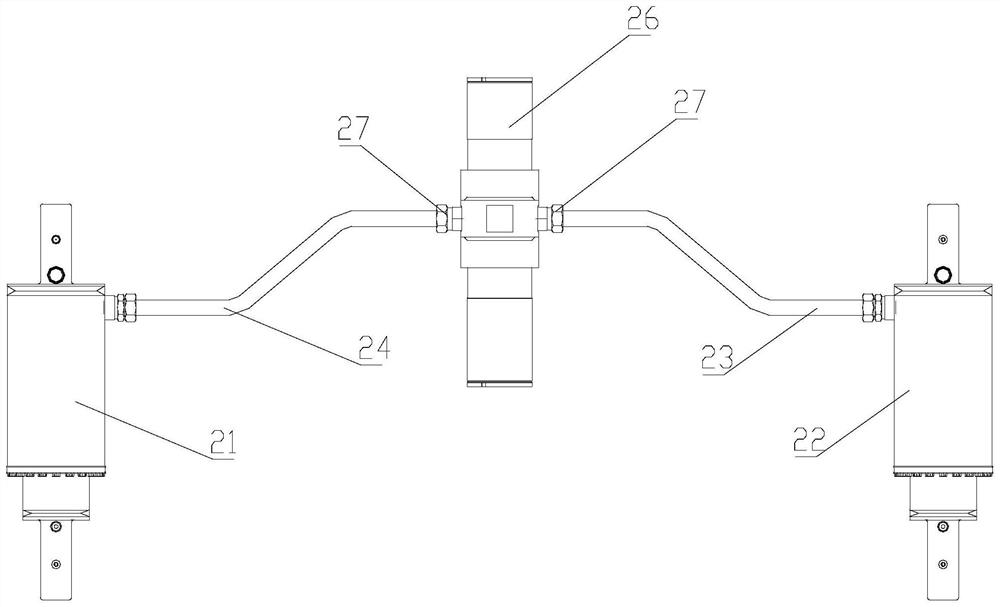

Energy accumulator vertically-arranged balance hydro-pneumatic suspension

PendingCN111688425AImprove reliabilitySuppress water shock wave oscillationResilient suspensionsVehicle springsHydraulic machineryGas spring

The invention discloses an energy accumulator vertically-arranged balance hydro-pneumatic suspension, and belongs to the technical field of hydraulic machinery. The suspension comprises a front hydro-pneumatic spring, a front balance pipeline, a rear hydro-pneumatic spring, a rear balance pipeline, an energy accumulator and pipeline joints. A main oil cavity oil port of the front hydro-pneumatic spring is connected to one end of a front balance pipeline, and the other end of the front balance pipeline is connected to a first oil inlet of the energy accumulator through the pipeline joint. A main oil cavity oil port of the rear hydro-pneumatic spring is connected to one end of the rear balance pipeline, and the other end of the rear balance pipeline is connected to a second oil inlet of theenergy accumulator through the pipeline joint to form balance suspension. A front wheel hydro-pneumatic spring oil chamber is communicated with a rear wheel hydro-pneumatic spring oil chamber, the energy accumulator is arranged outside, the single-wheel impact load is greatly reduced, the tire grounding capacity is remarkably improved, and wide application prospects are achieved in the fields of mining machineries and the like.

Owner:CHINA NORTH VEHICLE RES INST

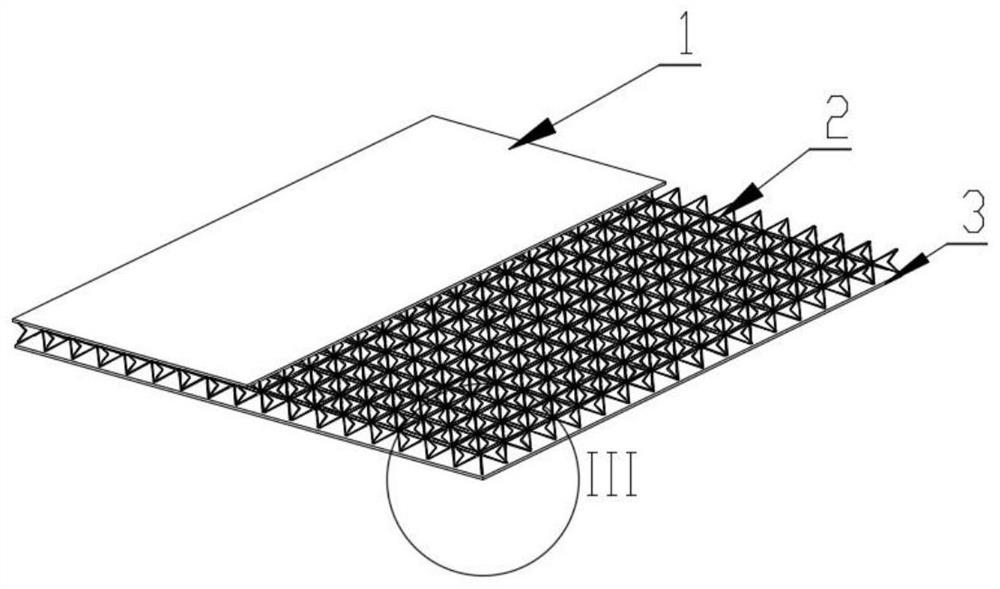

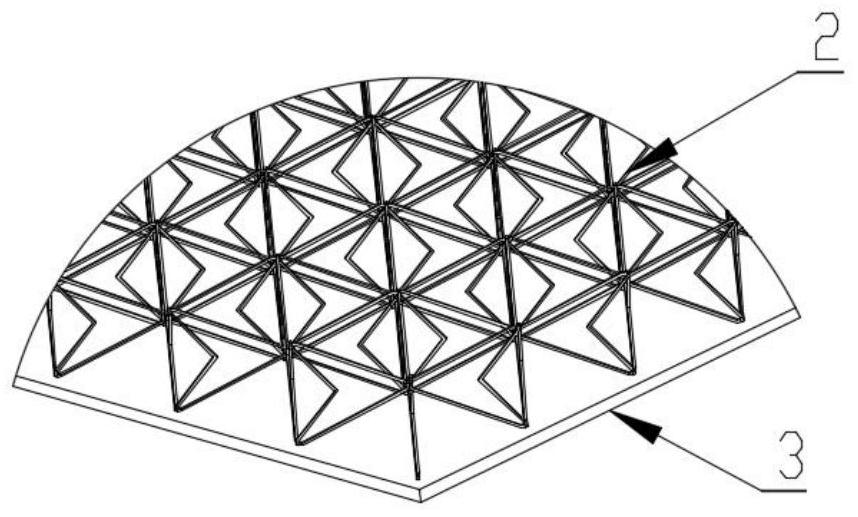

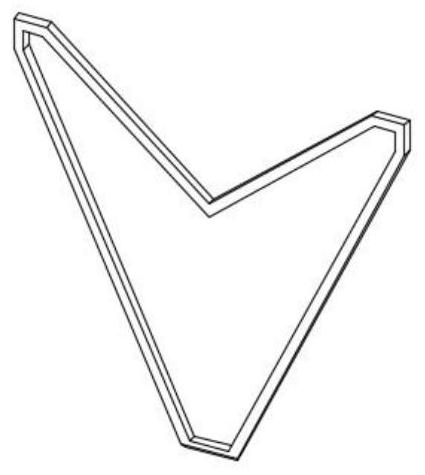

Double-arrow type negative poisson ratio honeycomb sandwich plate

PendingCN114161778AHas a negative Poisson's ratio effectStrong vibration dampingSuperstructure subunitsBumpersHoneycombEngineering

The invention discloses a double-arrow type negative poisson ratio honeycomb sandwich plate which is characterized by comprising an upper panel, a sandwich core and a lower panel, the sandwich is arranged between the upper panel and the lower panel and is fixedly connected with the upper panel and the lower panel; the sandwich layer is in a double-arrow-shaped negative poisson ratio honeycomb layer shape and is formed by regularly arranging double-arrow-shaped negative poisson ratio cell elements and vertically arranging the double-arrow-shaped negative poisson ratio cell elements between the upper panel and the lower panel; the double-arrow-shaped negative Poisson's ratio honeycomb sandwich plate is composed of the upper aluminum alloy panel, the lower aluminum alloy panel and the middle double-arrow-shaped negative Poisson's ratio honeycomb sandwich layer, a double-arrow-shaped structure is used as a cell element, the double-arrow-shaped structure has the negative Poisson's ratio effect, when the double-arrow-shaped structure is pressed, the two tail ends of an arrow draw close to the inner side, and the negative Poisson's ratio of the double-arrow-shaped structure is increased. Compared with a traditional laminated plate interlayer mode, buffering, vibration reduction and impact resistance are higher.

Owner:KUNMING UNIV OF SCI & TECH

A coupler buffer

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

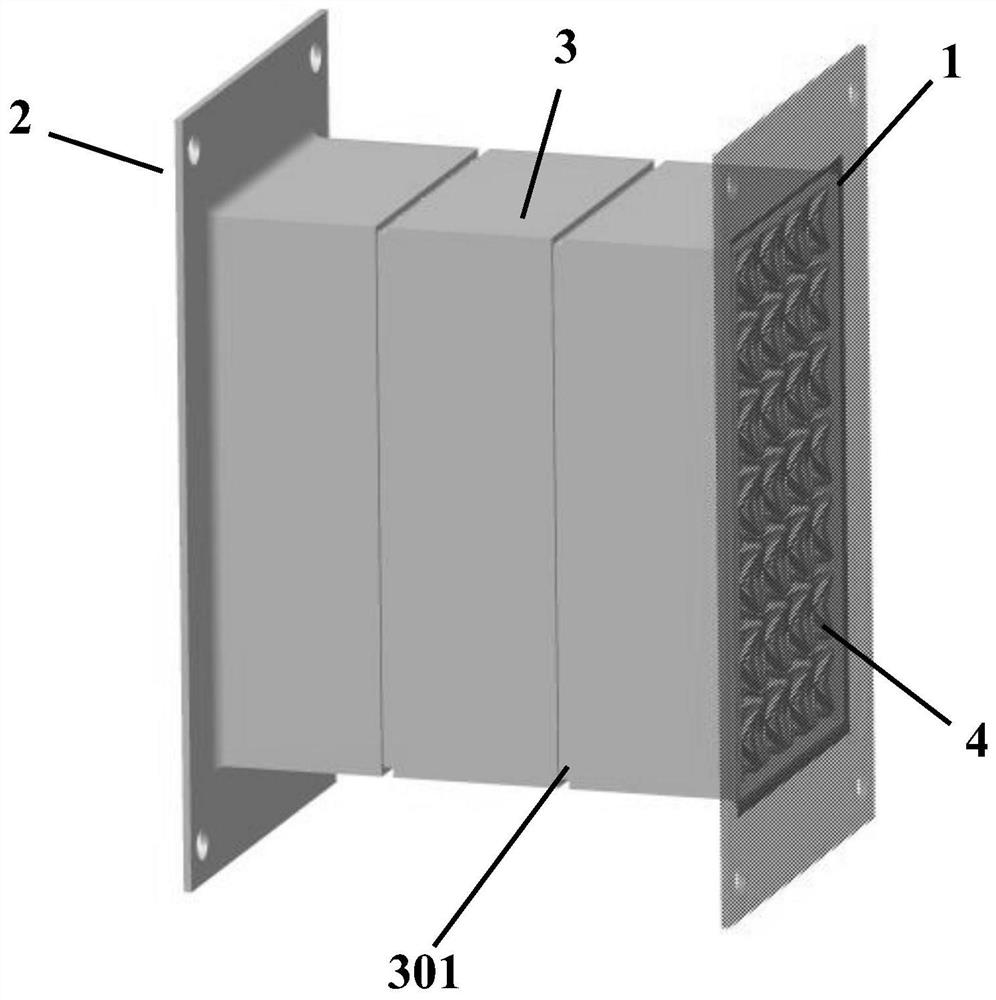

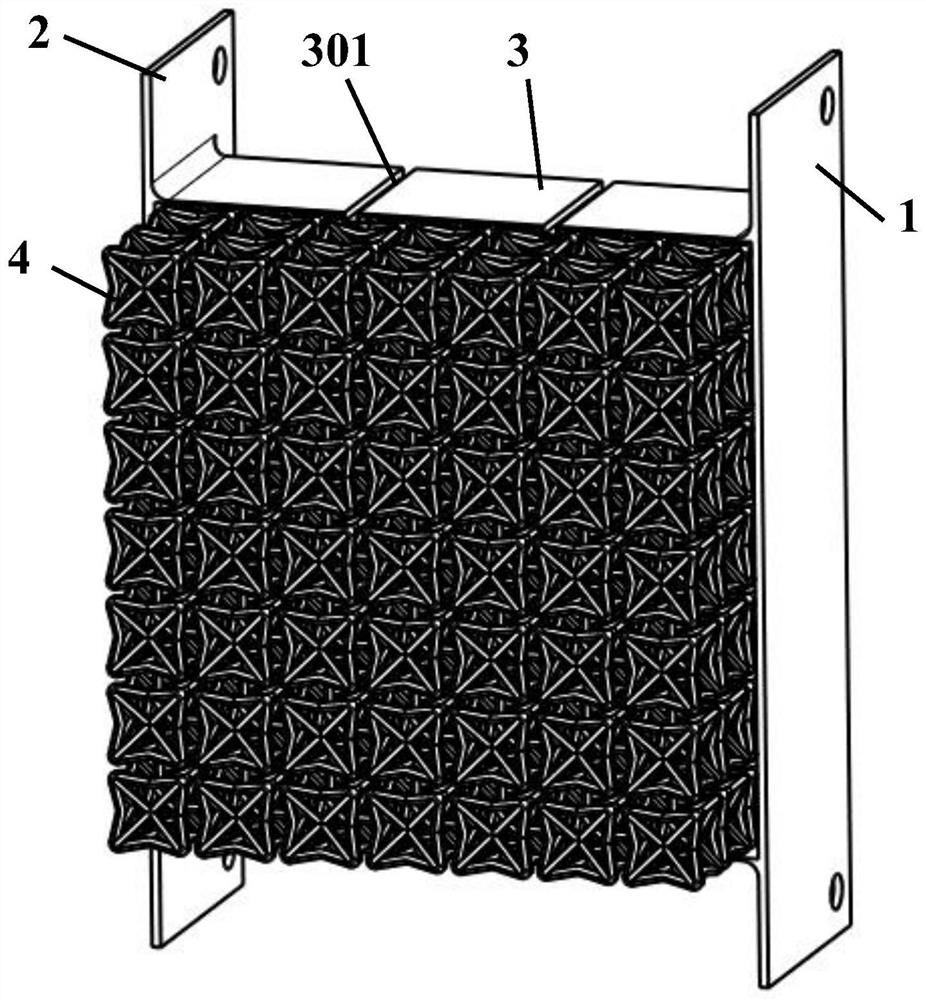

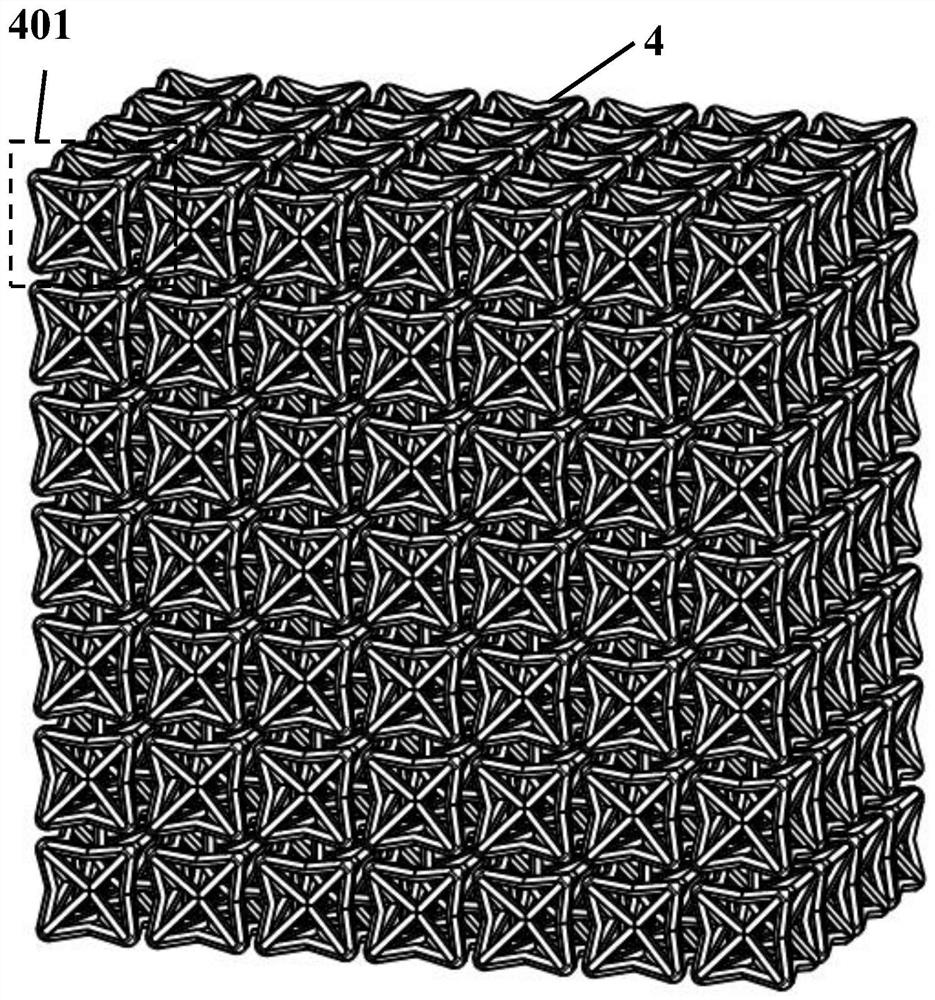

Energy-absorbing box based on three-dimensional structure core of concave polyhedron with negative Poisson's ratio

The invention discloses an energy-absorbing box based on a three-dimensional structure inner core of a concave polyhedron with negative Poisson's ratio. The box body and the three-dimensional inner core of the concave polyhedral negative Poisson's ratio structure filled in the inner cavity of the box; the inner core is formed by arranging and connecting multiple concave polyhedral negative Poisson's ratio unit cell structures in a three-dimensional direction. The energy-absorbing box of the present invention combines the negative Poisson's ratio three-dimensional structure, so that the energy-absorbing box has a negative Poisson's ratio and stiffness enhancement characteristics in the impact direction, which can simultaneously improve the energy-absorbing effect under multiple working conditions, and improve the performance of the vehicle. crash safety performance.

Owner:NANJING UNIV OF SCI & TECH

A kind of ultra-high viscosity and high sunlight reflectance waterproof and heat-insulating coating and preparation method thereof

ActiveCN108059891BReduce the ratioIncreased hemispherical emissivityAntifouling/underwater paintsPaints with biocidesMicrosphereDefoaming Agents

Owner:哈尔滨拓百世环保涂料有限公司

Impact-resistance and energy-absorption lengthening bar for single prop

The invention discloses an impact-resistance and energy-absorption lengthening bar for a single prop. The impact-resistance and energy-absorption lengthening bar for the single prop comprises a sill pillar and a guide pillar. The lower part of the sill pillar is provided with a lower backing plate; the lower backing plate is fixedly connected with the sill pillar; a spring set which is formed by covering compound rubber springs with a tower-shaped spring is arranged in the sill pillar and above the lower backing plate; an upper backing plate is arranged above the spring set; an energy-absorption block is arranged above the upper backing plate; a high-strength pushing cylinder is arranged above the energy-absorption block; the high-strength pushing cylinder is tightly pressed onto the energy-absorption block; a slider is arranged above the high-strength pushing cylinder; the outer edge of the slider is provided with grooves; the guide pillar is arranged in the grooves of the slider and is fixedly connected with the slider; at least one metal energy-absorption cylinder is sheathed outside the guide pillar. According to the impact-resistance and energy-absorption lengthening bar for the single prop disclosed by the invention, by utilizing the characteristic that a high-strength elastic-plastic foam material of the energy-absorption block is extruded to be broken to absorb energy and by utilizing the non-elastic stiffness of the spring set, a support is prevented from generating resonance when being impacted, and meanwhile, the at least one metal energy-absorption cylinder sheathed outside the guide pillar is fractured to absorb the energy.

Owner:LIAONING TECHNICAL UNIVERSITY

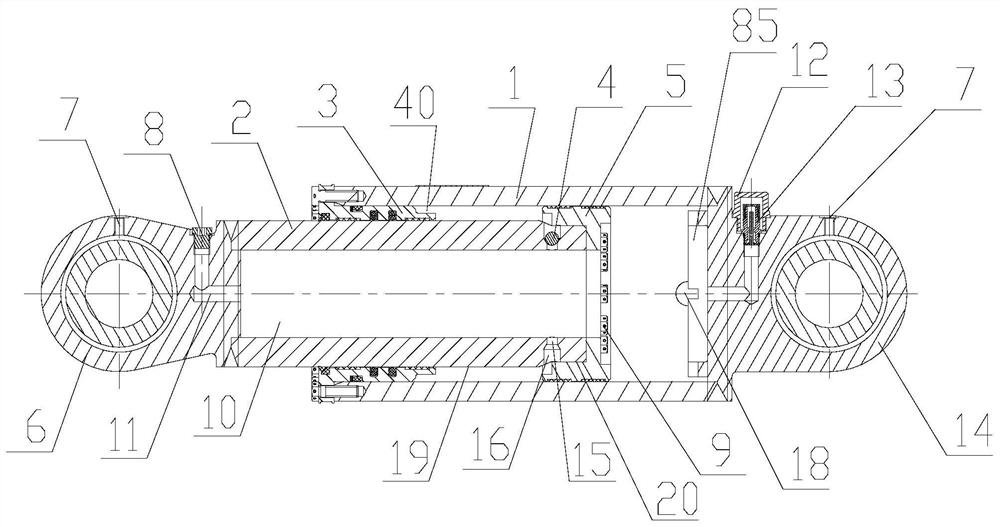

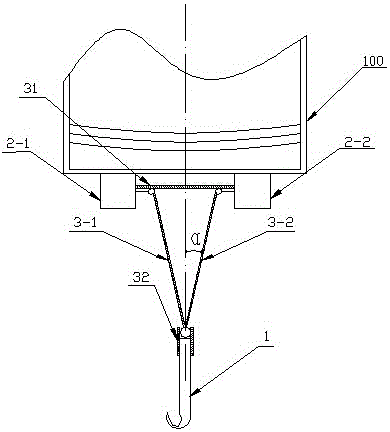

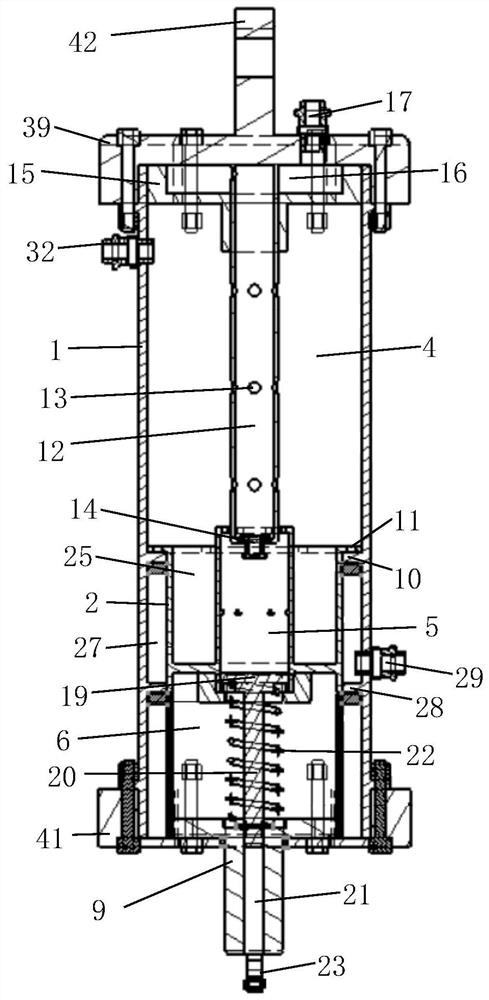

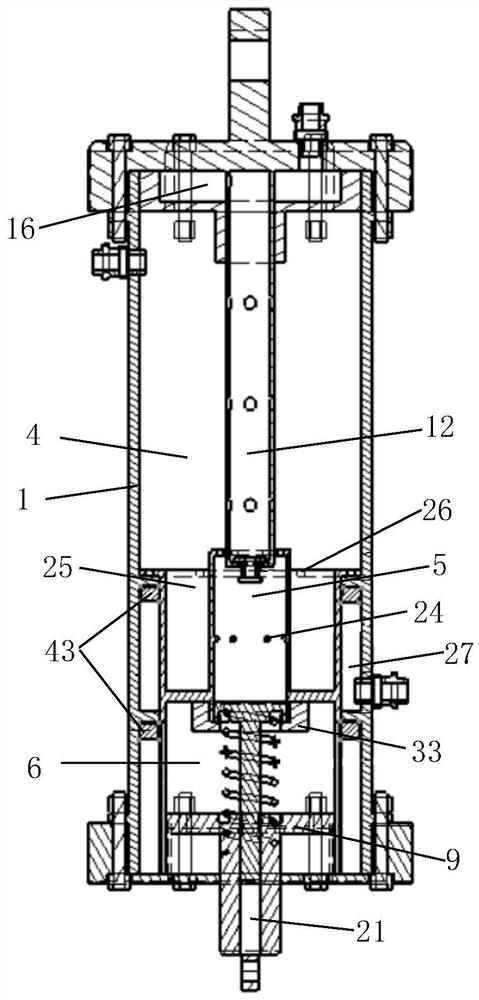

Aircraft landing gear buffer

ActiveCN111609073BImprove shock absorptionShock absorption stabilitySpringsAlighting gearAircraft landingMechanical engineering

The invention discloses an aircraft landing gear buffer, comprising: an outer cylinder; an inner cylinder movably arranged in the outer cylinder, and a first chamber and a second chamber whose volume changes with the movement of the inner cylinder are arranged between the inner cylinder and the outer cylinder. There is a third cavity inside the inner cylinder, at least one first damping hole is set between the first cavity and the second cavity, at least one second damping hole is set between the second cavity and the third cavity, and the second cavity There is buffer gas, and the third chamber is provided with buffer liquid; the piston assembly is located in the third chamber; one end of the moving assembly is connected to the piston assembly through an elastic member, and the other end extends out of the outer cylinder to connect with the impacted part; the moving assembly moves upward and compresses The elastic member produces elastic force for the first level of cushioning; the piston assembly moves upward to compress the buffer liquid for the second level of cushioning; the inner cylinder moves upward to compress the buffer gas for the third level of cushioning. The buffer has three levels of buffering, and automatically selects one or more levels of buffering according to the size of the impact load, which can absorb large impacts and filter small vibrations.

Owner:SHANGHAI INST OF TECH

A kind of composite material of microporous plate, microporous plate, light bulletproof armor and manufacturing method thereof

ActiveCN110220418BHigh impact strengthGood compatibilityProtective equipmentSynthetic resin layered productsElastomerAdhesive

The invention discloses a composite material of a microporous plate, a microporous plate, a light bulletproof armor and a manufacturing method thereof. The composite material is made of ultra-high molecular weight polyethylene material modified by graphene. Made of composite material with micropores on it, the bulletproof armor includes an elastomer layer, a ceramic layer and a microporous plate layer; the elastomer layer is an elastomer resin, and the thickness of the resin layer is 1‑15mm; the ceramic layer is bulletproof ceramics, the Bulletproof ceramics are one or more layers; the microporous plate layer is the aforementioned microporous plate, the microporous plate is a single layer or multiple layers, and the layers of the multilayers are bonded by adhesive, and the elastomer layer of the armor It is applied on the ceramic layer by spraying, and connected with the microporous plate layer by bonding; the beneficial effects of the invention are: the protection ability is improved, the weight is reduced, and the application effect is good.

Owner:JIANGXI HONGDU AVIATION IND GRP

High-strength toughness low-alloy wear-resistant steel excavator bucket tooth and preparation method thereof

ActiveCN105568142BPromote formationHigh surface hardnessSoil-shifting machines/dredgersAlloyHigh surface

The invention provides a high-strength toughness low-alloy wear-resistant steel excavator bucket tooth and a preparation method thereof. The preparation material is bainite / martensite multi-phase low-alloy wear-resistant steel, and the mass percentage of the composition is: C:0.40 ‑0.60, Si: 0.60‑1.2, Mn: 0.8‑1.2, Cr: 0.25‑0.35, Mo: 0.30‑0.50, Cu: 0.40‑0.60, Re: 0.2‑0.3, P: 0‑0.01, S: 0‑0.01 , and the rest are Fe and unavoidable impurities. The preparation method includes the following steps: 1) melting; 2) forming by lost foam casting; 3) air cooling to room temperature when the casting is cooled to 800-900°C after pouring; 4) heating the obtained casting to 820-860°C ℃ for austenitization; 5) Quenching; 6) Take it out when the surface of the casting is cooled to 200-320℃; 7) Immediately transfer the casting to a holding furnace at 260-330℃ for isothermal transformation of bainite, and then take it out air cooled. The obtained excavator bucket tooth has high surface hardness and good wear resistance, and the internal structure can ensure good toughness, and can absorb more impact energy when impacted, thereby improving impact resistance.

Owner:GUILIN UNIV OF ELECTRONIC TECH

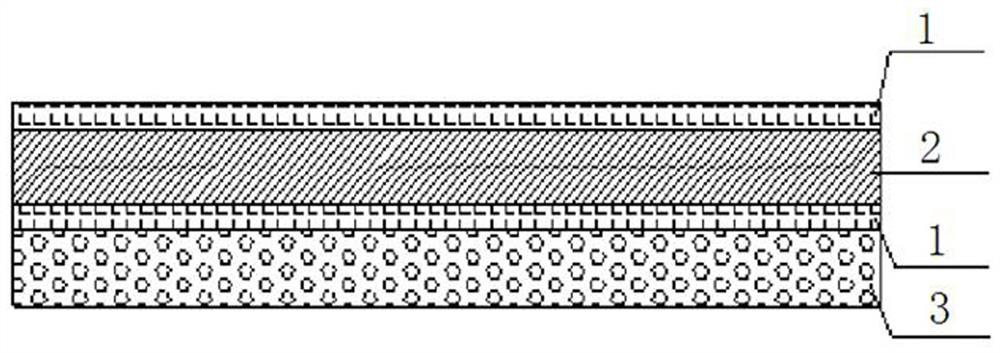

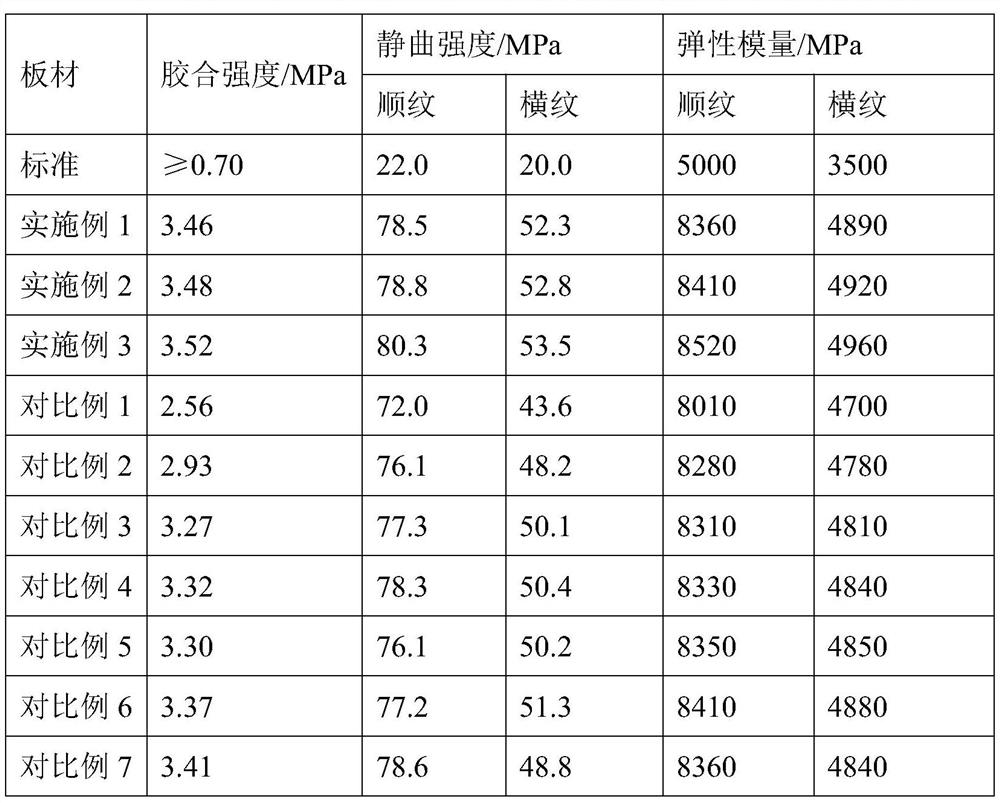

Adhesive capable of improving compression resistance of plywood and preparation method of adhesive

ActiveCN113683989AAdhesiveHigh bonding strengthNon-macromolecular adhesive additivesSolid waste managementPolymer sciencePolyvinyl alcohol

The invention discloses an adhesive capable of improving the compression resistance of plywood. The adhesive is prepared from the following raw materials in parts by weight: 10-30 parts of formaldehyde, 150-250 parts of melamine, 150-250 parts of ammonia water, 300-450 parts of urea, 1-3 parts of polyvinyl alcohol, 2-4 parts of modified graphene and 4-6 parts of silicate-containing inorganic filler. The preparation method comprises the following steps: S1, using formaldehyde to prepare a formaldehyde aqueous solution, adding modified graphene, and carrying out ultrasonic dispersion; S2, adjusting pH, conducting heating, and adding a first part of urea, melamine and ammonia water for a reaction; S3, adjusting the pH value, adding a second part of urea, and conducting stirring; and S4, adding a third part of urea, polyvinyl alcohol and silicate for reaction, adjusting the pH value, naturally conducting cooling to normal temperature, and conducting dehydrating to obtain the adhesive. The adhesive prepared by the invention is used for the plywood, the bonding strength of the plywood can be remarkably improved, and the plywood is excellent in mechanical property and high in compression resistance.

Owner:广西完美木业集团有限公司

Low-alloy bainite ductile iron oil quenching isothermal tempering heat treatment process

A low alloy bainite ductile iron oil quenching with temperature isothermal tempering heat treatment process includes: (1) heating a ductile iron work piece to be at 880 to 960 DEG C for the austenization; (2) quenching the work piece in machine oil; (3) taking out the ductile iron work piece when the surface temperature is 150 to 230 DEG C; (4) keeping the ductile iron work piece with temperature and rapidly burying sands for the heat preservation and the tempering for 6 to 8 hours; or burying sands for the heat preservation and the tempering for 1 to 3 hours and then taking the work piece out for the air cooling. Through refractory bricks and molding sands in an insulation packet or a ground pit, the process forms a reasonable temperature gradient from the inside of the ductile iron to the surface, a sands layer, the insulation packet or the ground pit. The slow and stable cooling speed which accords with the requirement is established. The isothermal tempering temperature is effectively controlled. The residue heat after the heat treatment on the ductile iron work piece is used to realize the isothermal transformation from austenite to bainite, which is more beneficial to the formation of bainite tissues. The obtained ductile iron work piece tissues have the advantages of reasonable structure and perfect comprehensive property and are especially applied to gears, crankshafts, grinding balls, etc.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Low-alloy bainite ductile iron abrading-ball

InactiveCN100584981CImprove impact resistancePromote formationFurnace typesHeat treatment furnacesChemical compositionHigh surface

A low alloy bainite ductile iron grinding ball is provided. The chemical compositions of the grinding ball (weight percentage) are as follows: 3.5 to 3.8 percent of C, 2.8 to 3.8 percent of Si, 0.1 to 0.5 percent of Mn, 0.15 to 0.35 percent of Cr, 0.35 to 0.5 percent of Mo, less than or equal to 0.03 percent of S, less than or equal to 0.1 percent of P, 0.03 to 0.08 percent of Mg, 0.5 to 1.5 percent of Cu, 0.01 to 0.03 percent of Bi and 0.02 to 0.07 percent of Re, and the rest is Fe. The ball is made through the following heat treatment steps: (1) heating the grinding ball to be at 880-960 DEG C; (2) quenching in mechanical oil; (3) taking the ball out when the surface temperature is 150-230 DEG C; (4) implementing the sands burying and the insulation tempering rapidly with temperature for 6-8h or taking the ball out for the air cooling after the sands burying and the insulation tempering for 1-3h. The obtained grinding ball has the advantages of reasonable organization structure, high surface strength, high hardness, good wear resistance, high inner toughness and perfect comprehensive property and is especially applied to crushing materials.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com