A kind of ultra-high viscosity and high sunlight reflectance waterproof and heat-insulating coating and preparation method thereof

A thermal insulation coating, high viscosity technology, applied in antifouling/underwater coatings, reflection/signal coatings, coatings, etc., can solve the problem of low reflection ratio, reduce the heat absorption capacity, improve the thermal insulation and waterproof function, The effect of reducing the scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

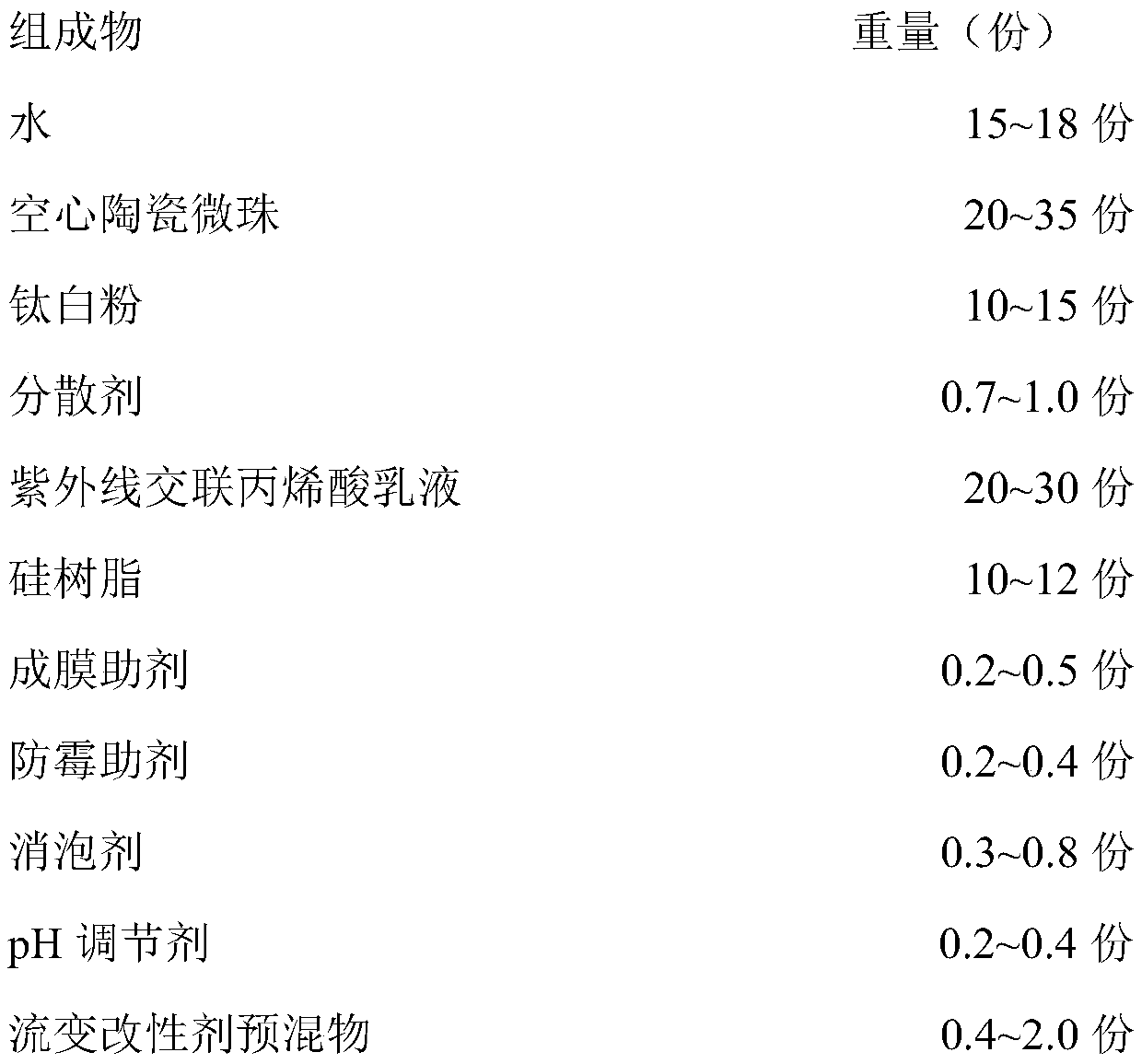

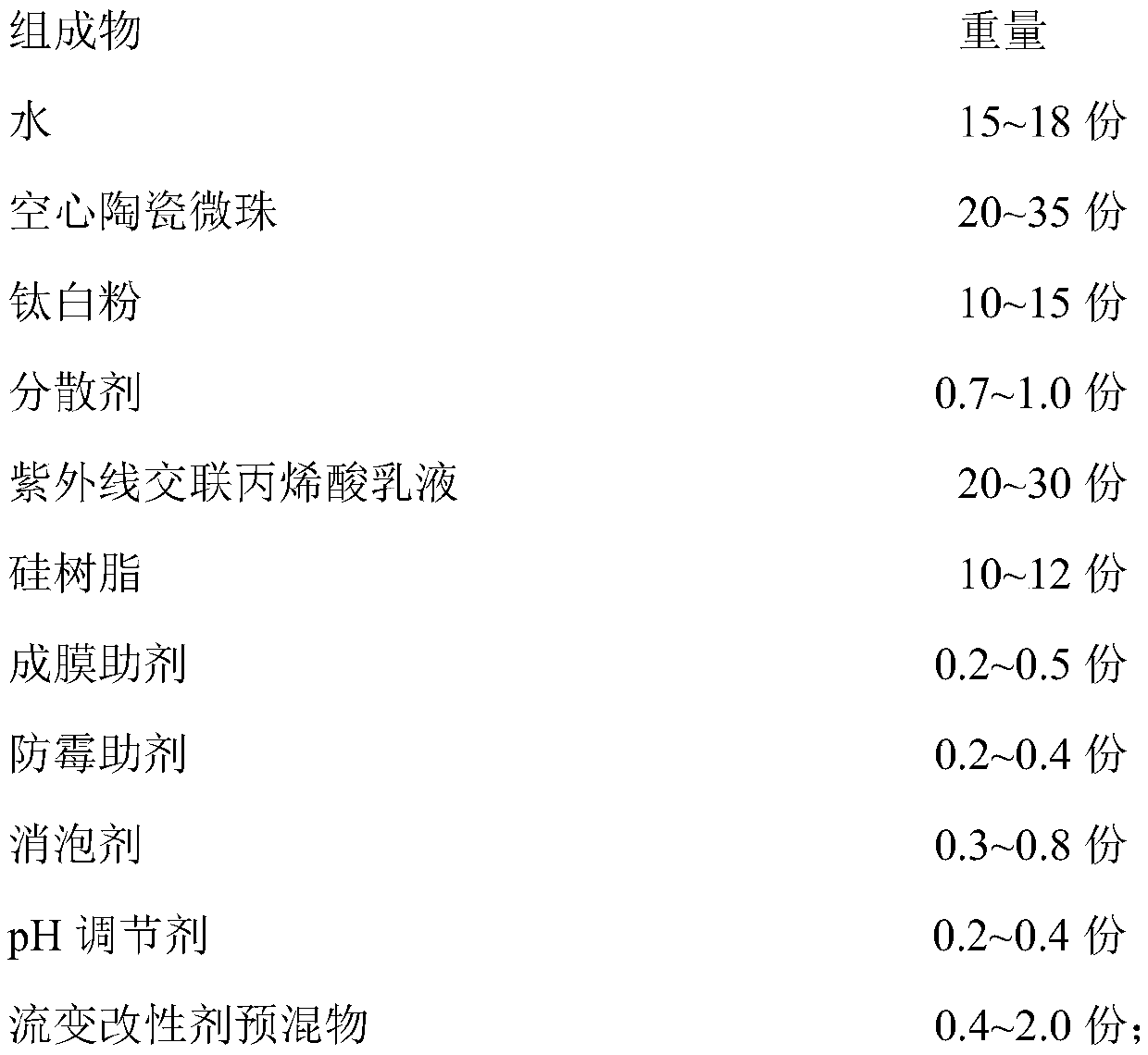

[0030] Embodiment 1: In this embodiment, the ultra-high viscosity and high sunlight reflectance waterproof and heat-insulating coating includes the following components in parts by weight:

[0031]

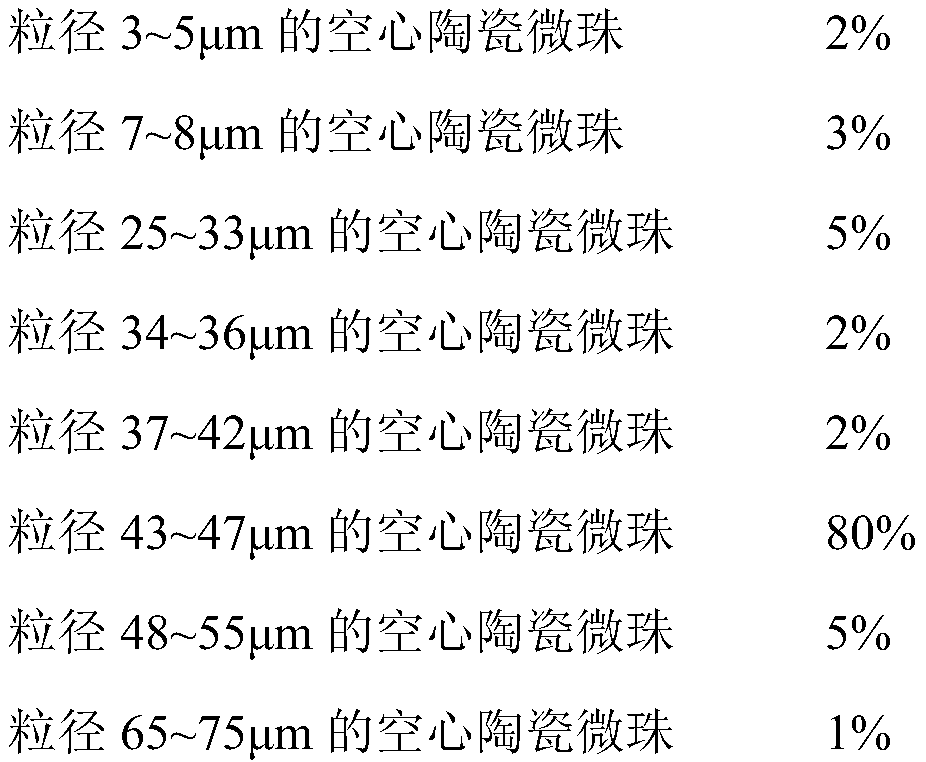

[0032] Among them, the hollow ceramic microspheres are made of 8 kinds of hollow ceramic microspheres with different particle sizes. The specific particle sizes and proportions are as follows:

[0033]

[0034]

[0035] The titanium dioxide is nanometer rutile titanium dioxide, and the particle size of the titanium dioxide is 10-350nm.

specific Embodiment approach 2

[0036] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the water is deionized water treated by RO membrane. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the dispersant is polycarboxylate, polyphosphate, polysiloxane, maleic anhydride-acrylic acid copolymer sodium salt, hydrophobic modified One or more mixtures of permanent acrylate ammonium salts. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com