Energy accumulator vertically-arranged balance hydro-pneumatic suspension

A technology of oil and gas suspension and accumulator, applied in the field of hydraulic machinery, can solve the problems of heavy body structure, complex mechanical balance suspension structure, increased maintenance cost, etc., so as to improve reliability, optimize pipeline layout, and restrain along the path. The effect of drag loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below with reference to the accompanying drawings and examples.

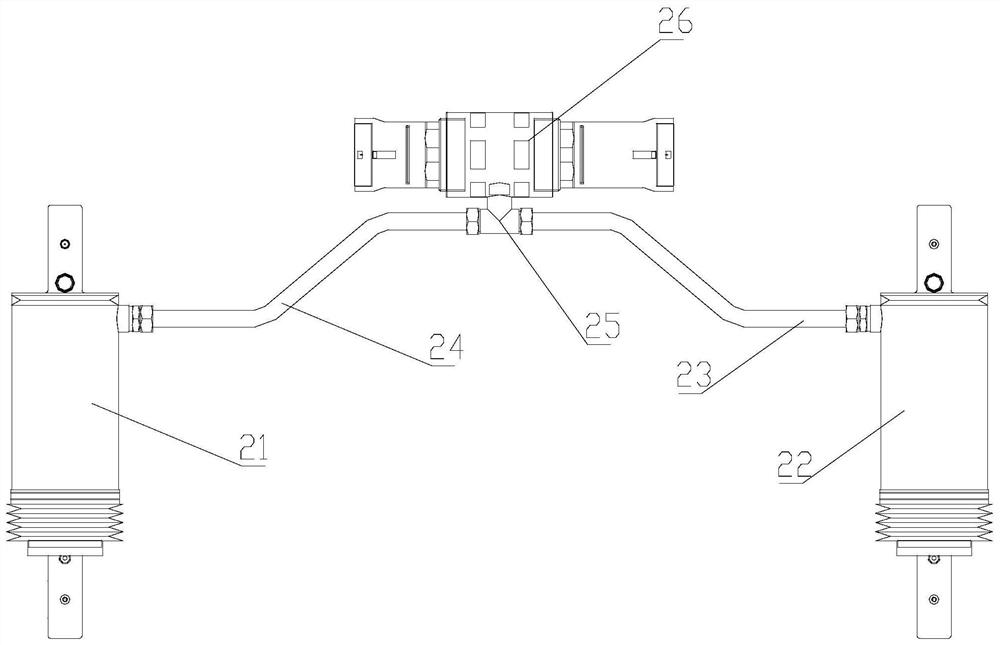

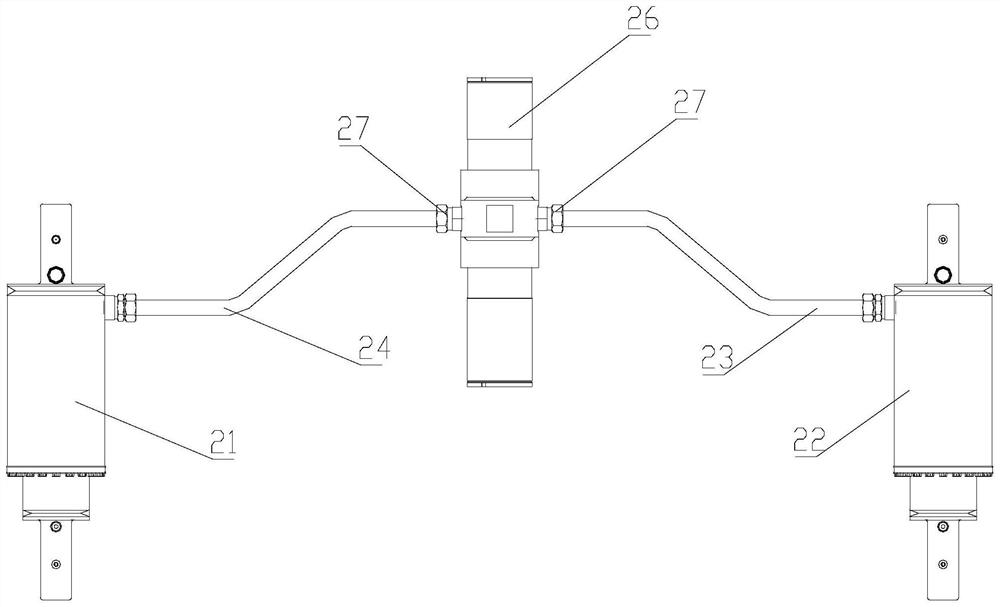

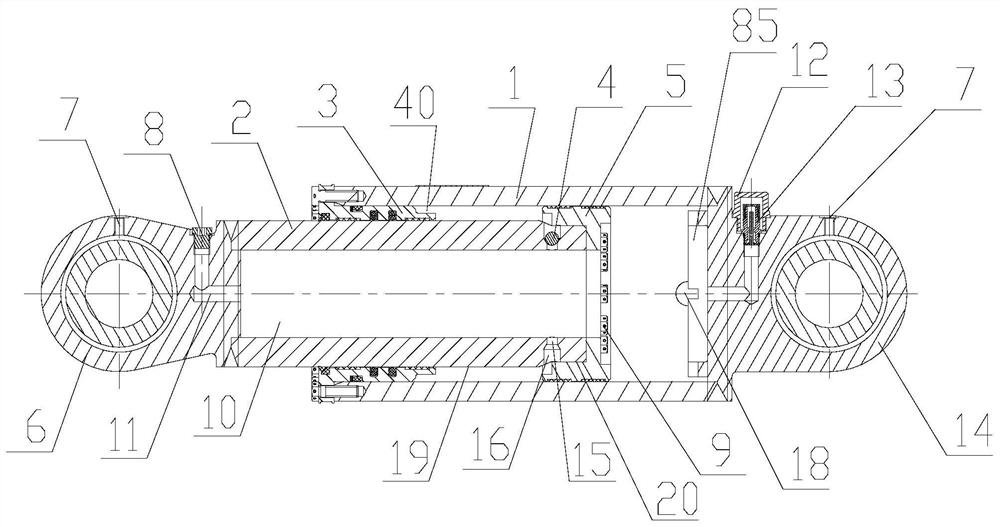

[0030] The invention designs a balanced oil-gas suspension structure, which has wide application prospects in the fields of mining machinery and multi-axle heavy-duty vehicles. Such as figure 1 with 5 As shown, it is a schematic diagram of the horizontal balance oil-air suspension structure of the accumulator. The communication port 18 of the main oil chamber of the front oil-gas spring 21 is connected to one end of the front balance pipeline 24, and the communication port 18 of the main oil chamber of the rear oil-gas spring 22 is connected to the One end of the rear balance pipeline 23 is connected, and further, the other end of the front balance pipeline 24 and the other end of the rear balance pipeline 23 are connected with the oil inlet of the accumulator 26 through the three-way joint 25, thereby forming a balance suspension. The internal high-pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com