Novel intercooler main board

A technology of intercooler and main board, which is applied in the direction of machines/engines, internal combustion piston engines, mechanical equipment, etc. It can solve the problems of not being able to meet the needs of light weight, increase the overall volume of the main board, and reduce the overall volume of the main board to achieve reduction Outline dimensions, simplification of structure, and reduction of external volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

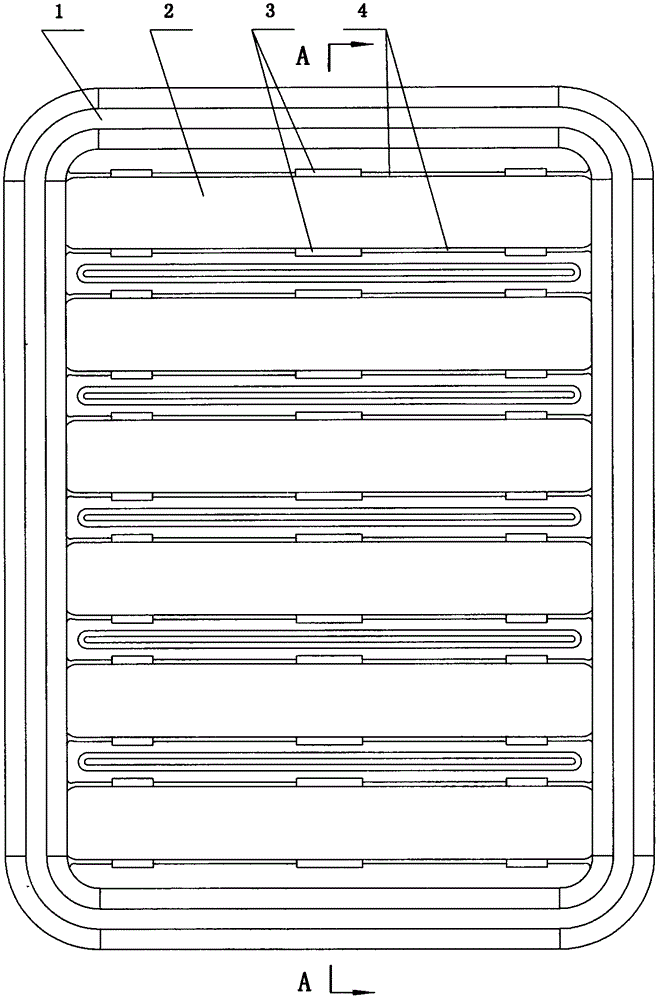

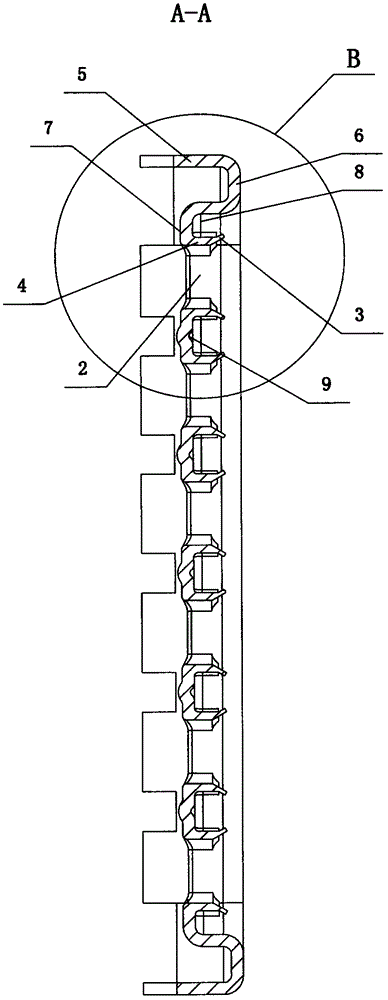

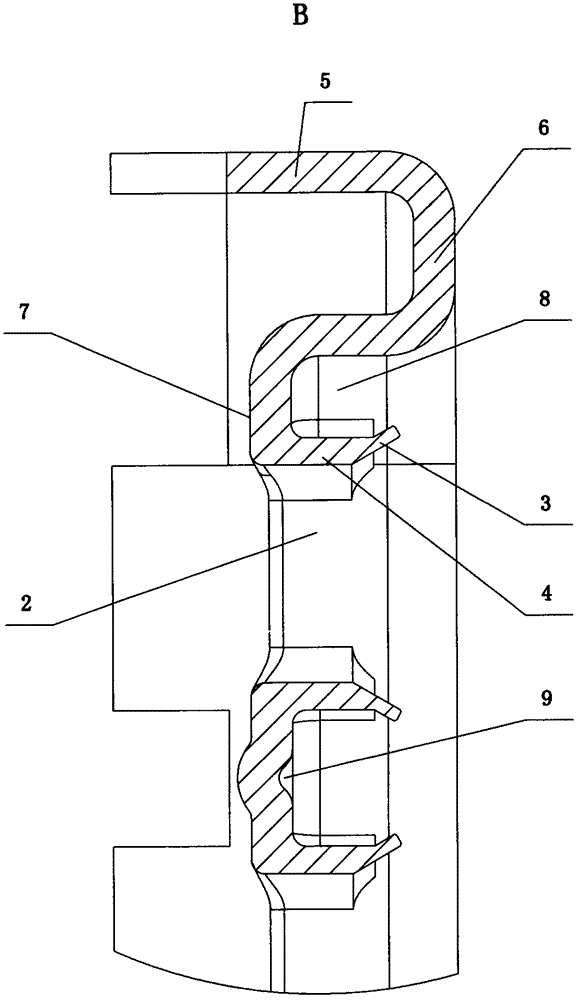

[0022] Depend on Figure 1 ~ Figure 3 It can be seen from the schematic structural diagram of the main board of the new intercooler of the present invention that it includes a main board body 1, and the main board body 1 is provided with a plurality of connection through holes 2 for connecting flat tubes of the intercooler. The long edge of the connecting through hole 2 described in the plane of the mainboard body 1 has a right-angled flange 4 integrated with the mainboard body 1, and the opening of the right-angled flange 4 is directed towards the inner side of the mainboard body 1, And the wide edge of the connecting through hole 2 is the side wall of the main board body 1 . The long side wall of the connecting through hole 2 and the flat tube of the intercooler are interference squeeze fit.

[0023] The mainboard body 1 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com