Heat collecting plate

A technology of heat collecting plate and plate body, applied in the field of heat collecting plate, can solve the problems of low heating efficiency and large heating area, and achieve the effect of improving safety, improving plate body strength and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

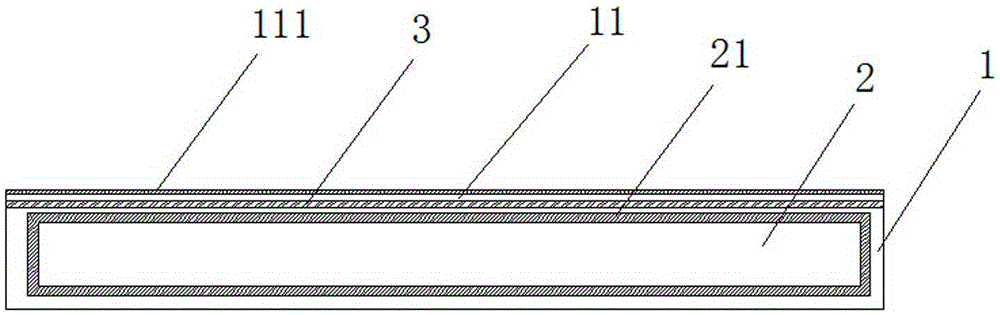

[0022] like figure 1 A heat collecting plate includes a plate body 1 and a working medium flow channel 2 formed in the plate body. The plate body 1 is provided with a functional surface 11 for absorbing heat, and a graphene heat absorbing film 111 is provided on the surface of the functional surface 11 . Graphene can not only absorb visible light and weak light emitted by the sun, but also absorb invisible infrared light and ultraviolet light. The graphene heat-absorbing film 111 covered on the surface of the functional surface 11 can absorb more light energy in the same heating time with the same heating area, so that the heat collecting plate products can be miniaturized and miniaturized, thus better The connection and integration of land and buildings. At the same time, graphene has good ultra-high thermal conductivity, which improves the heating efficiency of the heating plate. In addition, the graphene material has extremely high mechanical strength, which can effective...

Embodiment 2

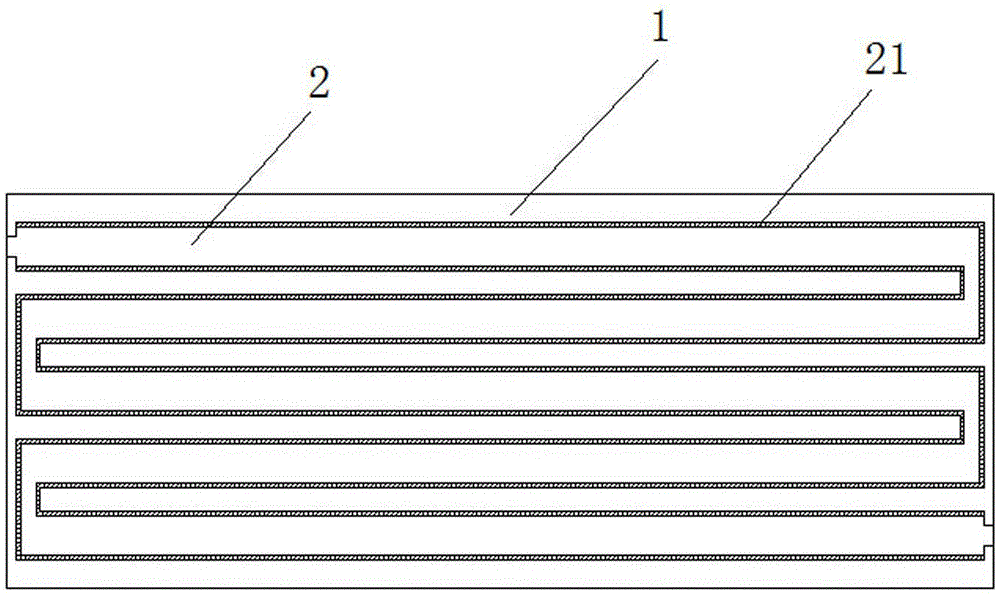

[0026] like figure 2 , the working medium channel 2 can be distributed in a serpentine shape in the plate body. The length of the working medium flow channel 2 is increased to improve the heating efficiency.

Embodiment 3

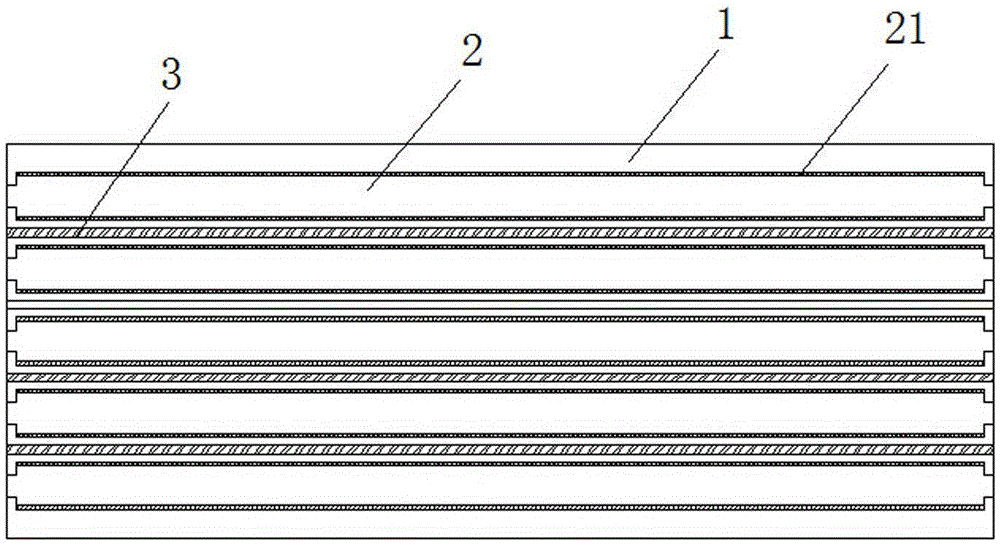

[0028] like image 3 , the working medium flow channel 2 may also have multiple, and the multiple working medium flow channels 2 are independent of each other. And a graphene heat conduction layer 3 is arranged between two adjacent working medium flow channels.

[0029] In addition, the plate body 1 can also be made of materials added with graphene particles. Graphene's good ductility, extremely high mechanical strength and ultra-high thermal conductivity improve the processing characteristics of the heat collector plate. The heat collector plate can be thinner and lighter, which greatly facilitates installation and reduces the risk factor of high-altitude operations.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com