Fused-sealing type heat-pipe vacuum heat collecting pipe

A technology of vacuum heat collector and heat pipe, applied in the field of vacuum heat collector and melt-sealed heat pipe vacuum heat collector, can solve the problems of no protective measures, easy leakage, easy stress concentration, etc., so as to avoid excessive stress concentration, facilitate fixation, reduce effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

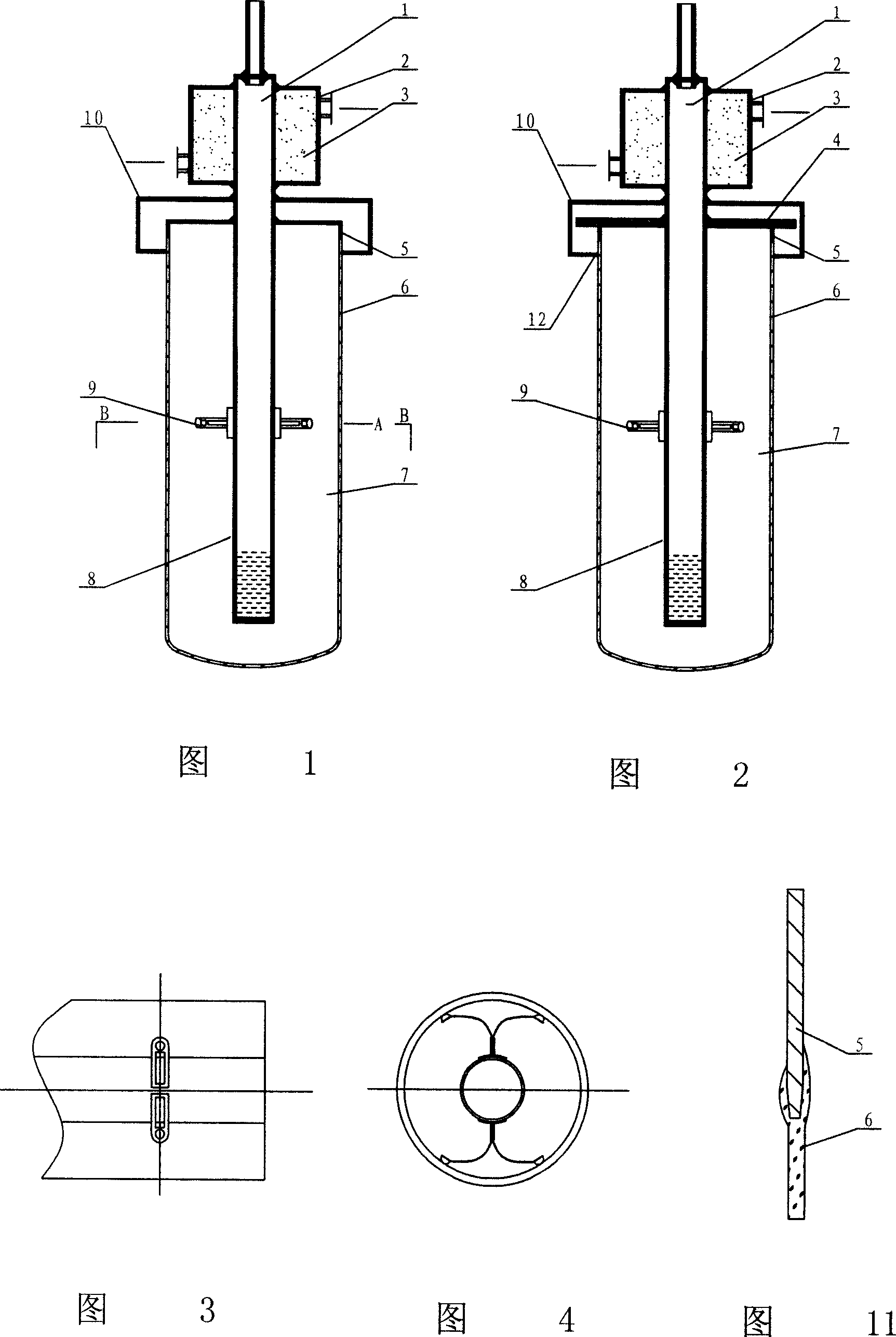

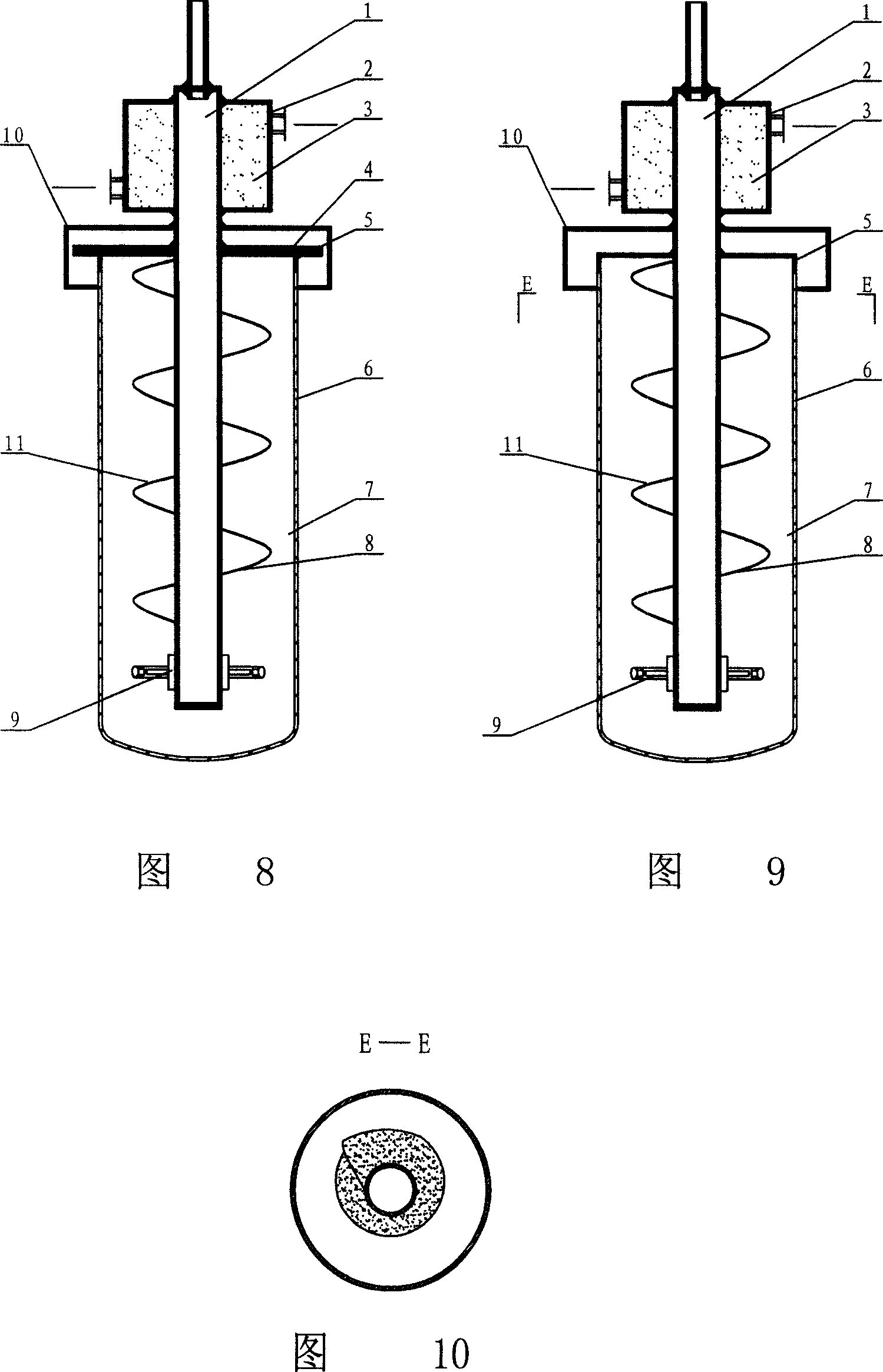

[0027] The fusion-sealed heat pipe vacuum heat collection tube of this embodiment is shown in Figure 1 , a glass outer tube 6 with one end closed is equipped with a heat pipe 1 whose lower surface is coated with a sunlight-absorbing coating 8 . The upper part of the heat pipe is sealed and welded with a cooling jacket 2 with an inlet and an outlet. The middle part of the heat pipe is welded and airtightly connected with the glass outer nozzle through Kovar 5 with flanging. A vacuum cavity 7 is formed between the glass outer tube 6 and the heat pipe 1 . The heat pipe section above the Kovar alloy fixes the upper plate of the protective cover 10, and the outer glass tube 6 cooperates with the lower plate of the protective cover. Seamed hood.

[0028] In order to eliminate the stress of thermal deformation difference on the sealing joint, the lower part of the heat pipe is equipped with a self-centering support, as shown in Figure 3 and Figure 4. There are two sets of V-shaped...

Embodiment 2

[0032] The fusion-sealed heat pipe vacuum heat collection tube of this embodiment is shown in Figure 2, and its structure is basically the same as that of Embodiment 1. The difference is that the middle part of the heat pipe 1 is inserted into the center hole of the metal flange 4 for sealing and welding. One end of the Kovar alloy ring 5 is sealed and welded to the end face near the periphery of the flange, and the other end of the Kovar alloy ring 5 and the glass outer nozzle form a plug-in fusion seal connection structure shown in FIG. 11 . In this way, the sealing effect is better, the connection strength is higher, the amount of Kovar alloy can be reduced, and at the same time, it is beneficial to the fixing of the heat collecting tube in the future system application.

[0033] In addition, the glass outer tube 6 cooperates with the inner opening of the lower plate of the protective cover to be inlaid with a bezel 12 made of heat-insulating material, so it can directly con...

Embodiment 3

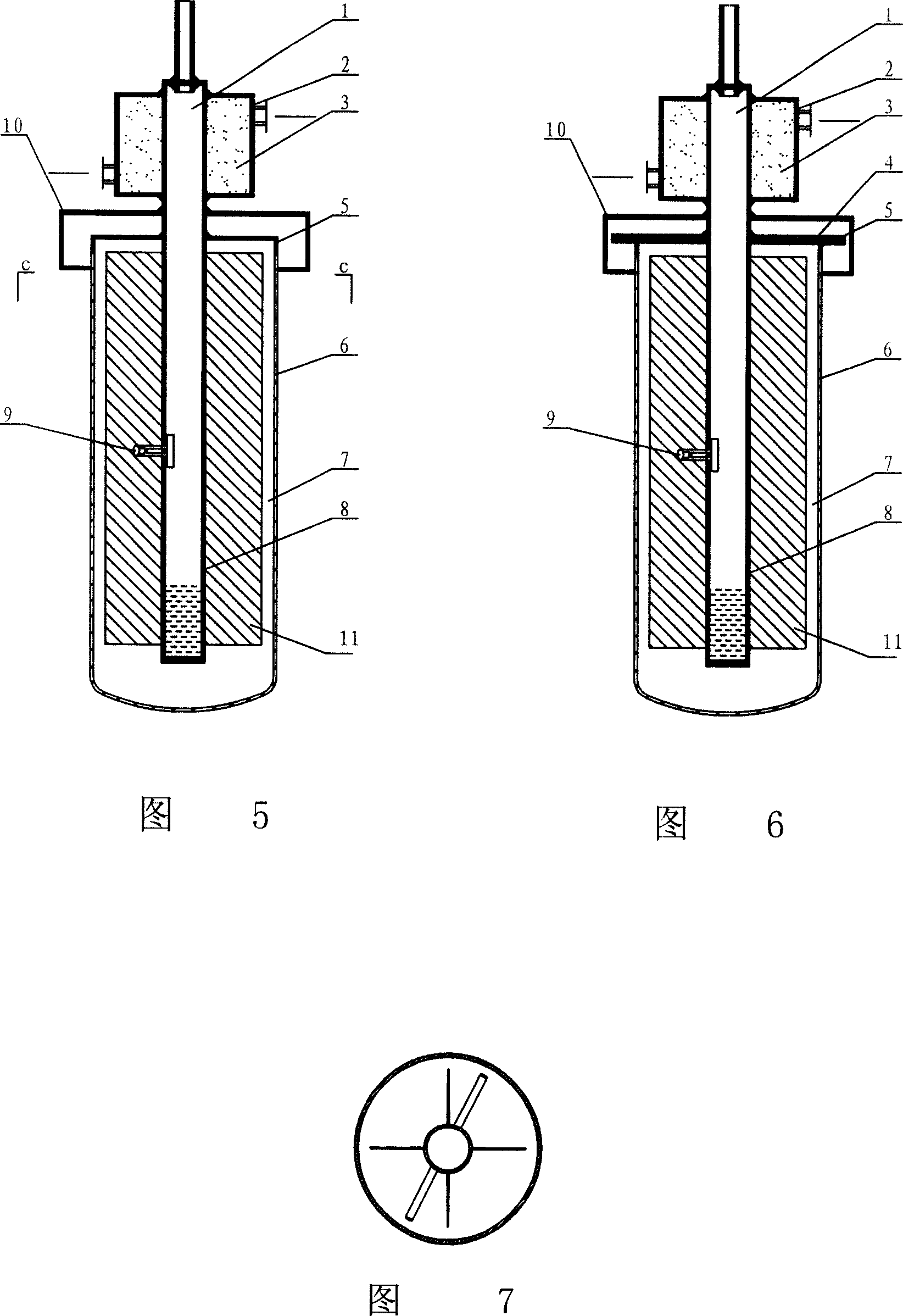

[0035] The fusion-sealed heat pipe vacuum heat collection tube of this embodiment is shown in Figure 5, and the structure is basically the same as that of Embodiment 1, the difference is that the cross-shaped fin 11 with cross-section as shown in Figure 7 is welded on the bottom of the heat pipe (of course it can also be It is a glyph fin), so it is more conducive to absorbing sunlight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com