Method for testing oil absorption volume of titanium dioxide

A test method, technology of titanium dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The viscosity values of titanium dioxide samples 1, 2, 3, 4 and 5 with known oil absorption were measured by the following method.

[0027] Specific methods: 1. Accurately weigh 210g of refined linseed oil, pour it into a 500mL container, place the container on a high-speed disperser, fix it with a clamp, turn on the disperser at a speed of 500r / min, and preliminarily disperse the linseed oil; 2. Accurately weigh 140g of titanium dioxide sample with known oil absorption, slowly pour the titanium dioxide into the refined linseed oil with a spatula, the addition of titanium dioxide is completed within 1min; 3. Increase the speed of the disperser to 1500r / min, Time for 10 minutes; 4. After the dispersion is completed, remove the slurry and use a rotational viscometer to test its viscosity value. This step should be completed within 2 minutes.

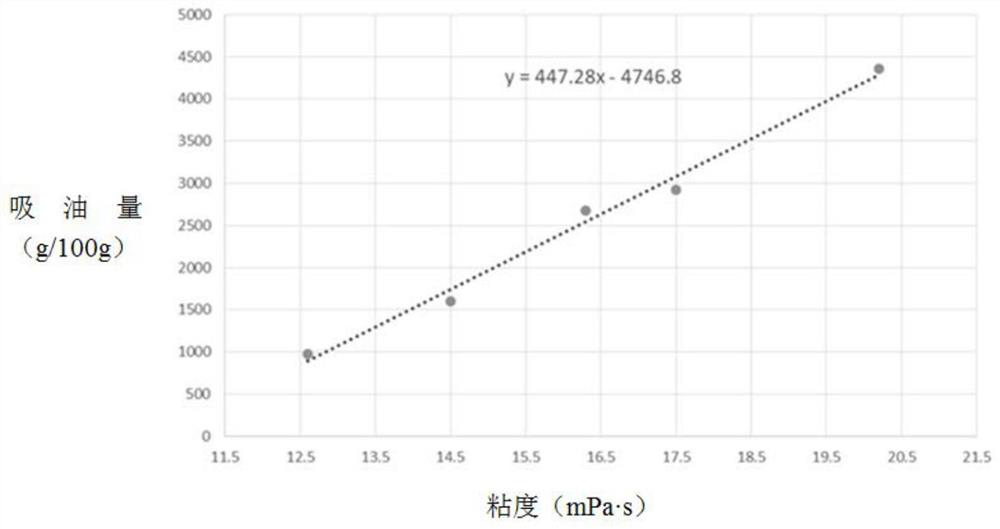

[0028] The oil absorption and viscosity values of samples 1-5 are shown in Table 1. According to the oil absorption and viscos...

Embodiment 2

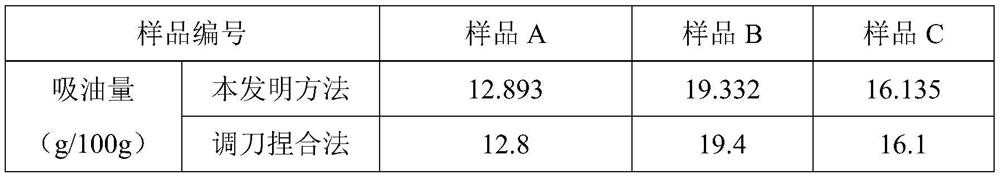

[0033] Adopt the method in the embodiment 1 of the titanium dioxide sample B to be tested, measure its viscosity value, its viscosity value is 3900mPa·s, this viscosity value is brought into the relational formula that embodiment 1 obtains, obtains that its oil absorption is 19.332g / 100g.

Embodiment 3

[0035] Adopt the method in the embodiment 1 of the titanium dioxide sample C to be tested, measure its viscosity value, its viscosity value is 2470mPa·s, this viscosity value is brought into the relational formula that embodiment 1 obtains, obtains that its oil absorption is 16.135g / 100g.

[0036] The oil absorption of titanium dioxide samples A, B, and C were tested by the traditional kneading method, and the oil absorption values obtained are shown in Table 2.

[0037] Table 2

[0038]

[0039] It can be seen from Table 2 that the oil absorption measured by the method of the present invention is close to the value obtained by the knife adjustment kneading method, and within the normal test error range, it can meet the test accuracy requirements of the titanium dioxide industry for the oil absorption index.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com