Device for testing high-pressure gas permeability of sealing material in tensile state and application

A sealing material and high-pressure gas technology, which is applied in measurement devices, analytical materials, permeability/surface area analysis, etc., can solve the problems of destroying the pressure sensor and the pressure value of the low-pressure chamber has not changed for a long time, and achieves a reasonable overall structure design. Intuitive measurement, avoiding pressure sensor damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

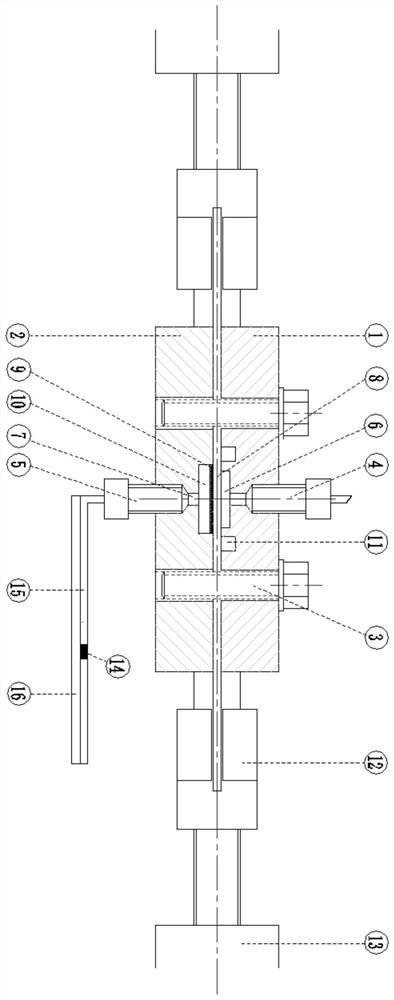

[0044] A device for testing the high-pressure gas permeability of sealing materials in tension, such as figure 1 , the device includes: a sealing box, used for placing the sealing material sample 8; a stretching mechanism, used for stretching the sealing material sample 8; a permeable gas measuring mechanism, used for testing the gas permeability coefficient of the sealing material sample 8;

[0045]The stretching mechanism is clamped at both ends of the sealing material sample 8. The permeable gas measuring mechanism includes a gas inlet unit and a gas receiving unit respectively located on both sides of the sealing material sample 8. The gas receiving unit is provided with a signal component for monitoring gas.

[0046] The sealing box includes an upper plate 1 and a lower plate 2 connected by connecting bolts 3 , and a sealing material sample 8 is located between the upper plate 1 and the lower plate 2 . The high pressure chamber 6 and the low pressure chamber 7 are also lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com