Chip tester

A technology of chip testing and test bench, which is applied in the direction of electronic circuit testing, measuring electronics, measuring devices, etc., can solve problems such as inconsistency and unstable test data, eliminate fatigue problems, eliminate small rotation offsets, and ensure accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

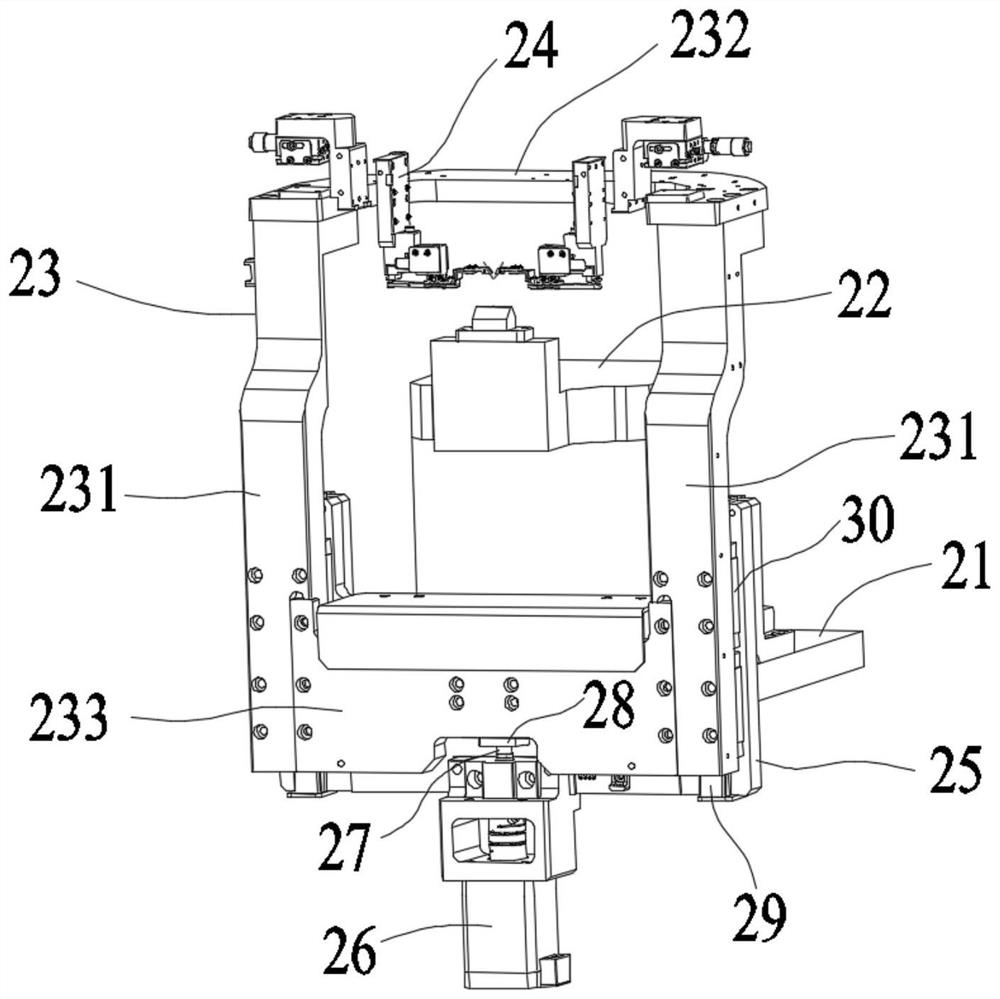

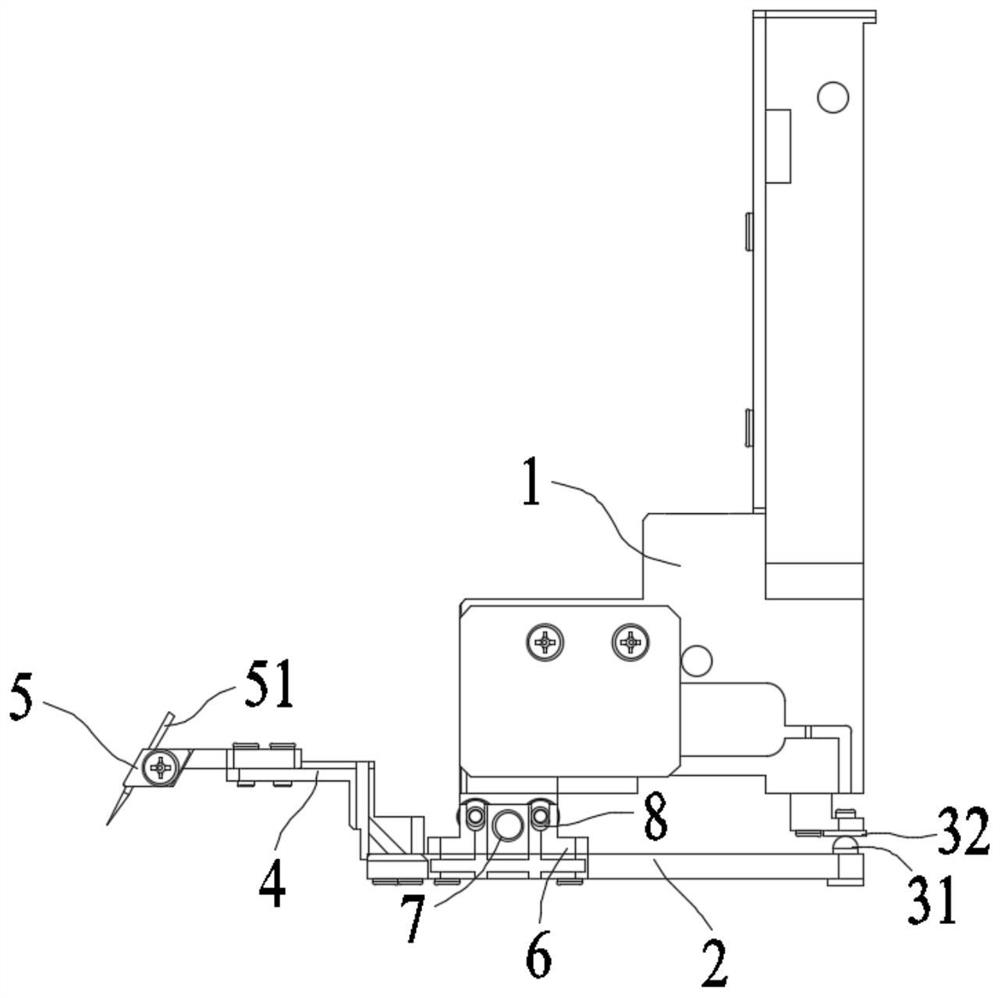

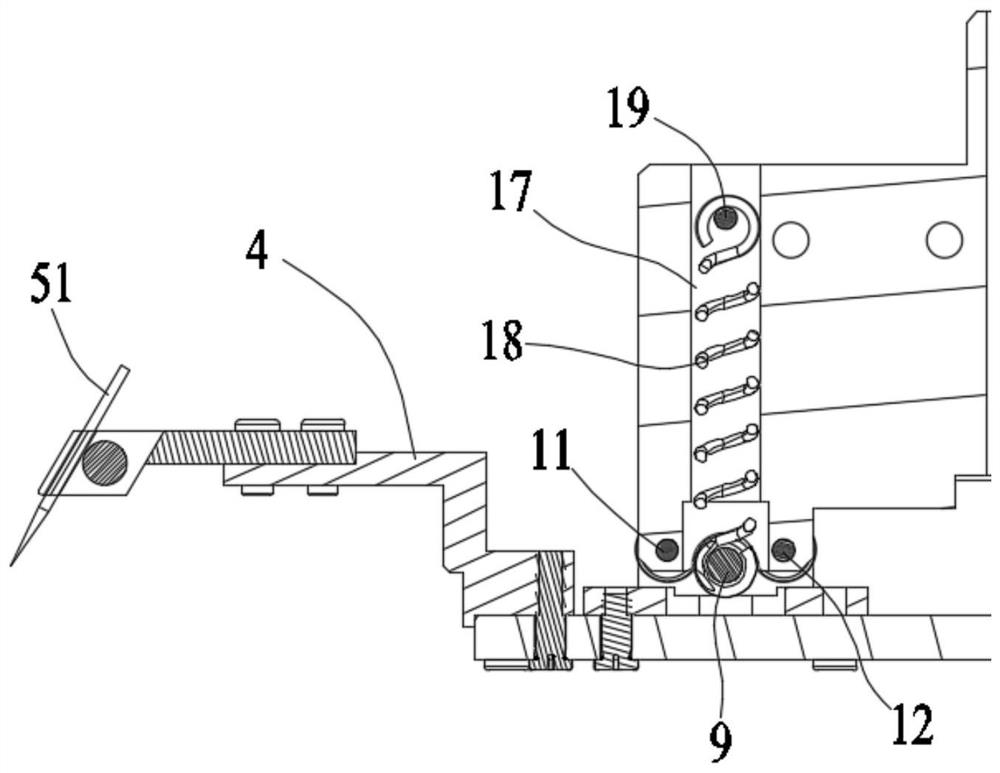

[0028] Embodiment 1: A chip testing machine, a substrate 21, a test platform 22 installed on the upper surface of the substrate 21, a drive bracket 23 installed on the outside of the substrate 21, and a test probe mounted on the drive bracket 23 and located above the test platform 22 Assembly 24, the test probe assembly 24 includes: a body 1 connected to the drive bracket 23, a support plate 2, a probe 51 for contacting the chip to be tested and a moving point contact probe 31, and one end of the support plate 2 is installed There is a cantilever 4, the other end of which is equipped with the moving point contact probe 31, and one side of the lower end surface of the body 1 is provided with a static point contact probe 32 which is located at the top of the moving point contact probe 31 and corresponds to it, when the probe is in contact with the chip to be tested When in contact, the dynamic point contact probe rotates with the support plate away from the static point contact p...

Embodiment 2

[0035] Embodiment 2: A chip testing machine, a substrate 21, a test bench 22 installed on the upper surface of the substrate 21, a drive bracket 23 installed on the outside of the substrate 21, and a test probe mounted on the drive bracket 23 and positioned above the test bench 22 Assembly 24, the test probe assembly 24 includes: a body 1 connected to the drive bracket 23, a support plate 2, a probe 51 for contacting the chip to be tested and a moving point contact probe 31, and one end of the support plate 2 is installed There is a cantilever 4, the other end of which is equipped with the dynamic point contact probe 31, and one side of the lower end surface of the body 1 is provided with a static point contact probe 32 located on the upper part of the dynamic point contact probe 31 and corresponding to it, and the cantilever 4 is far away from the support plate 2 one end is fixed with a probe holder 5 on which the probe 51 is installed;

[0036] An adapter seat 6 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com