Test method for laser chip

A test method and chip technology, applied in the direction of electronic circuit testing, measuring electricity, measuring devices, etc., can solve problems such as inconsistency and test data instability, eliminate fatigue problems, eliminate small rotational offsets, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

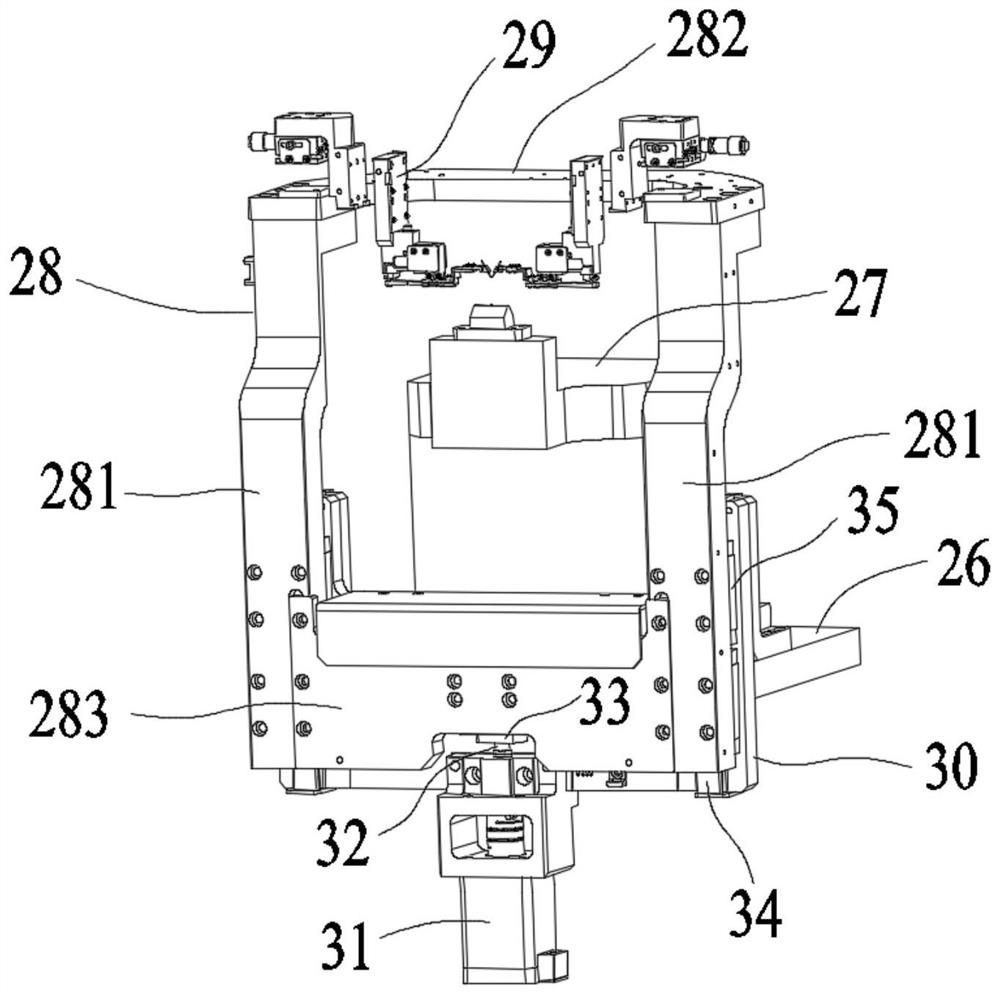

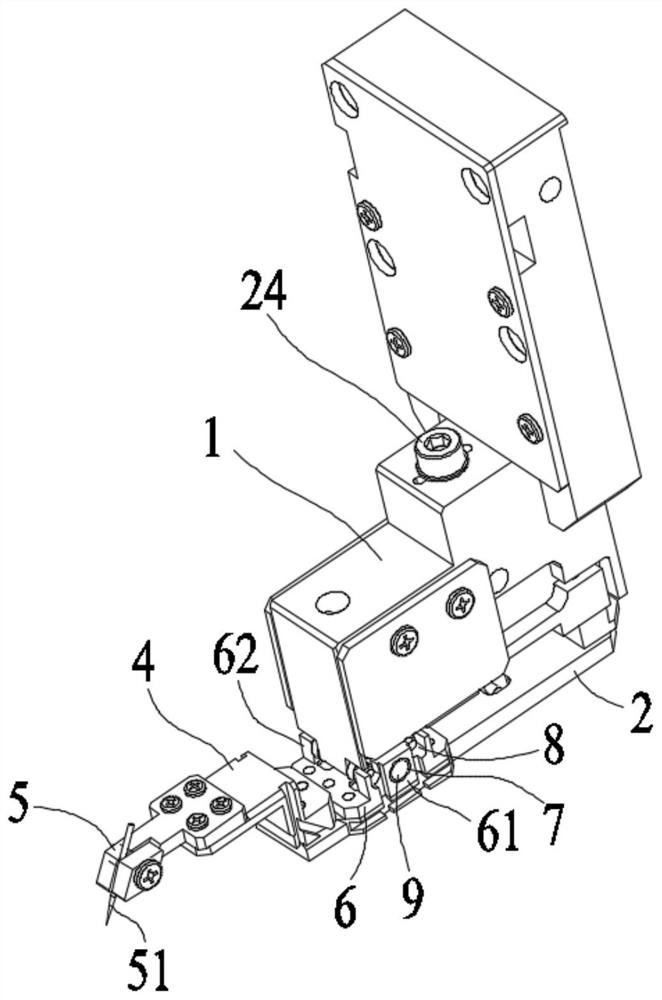

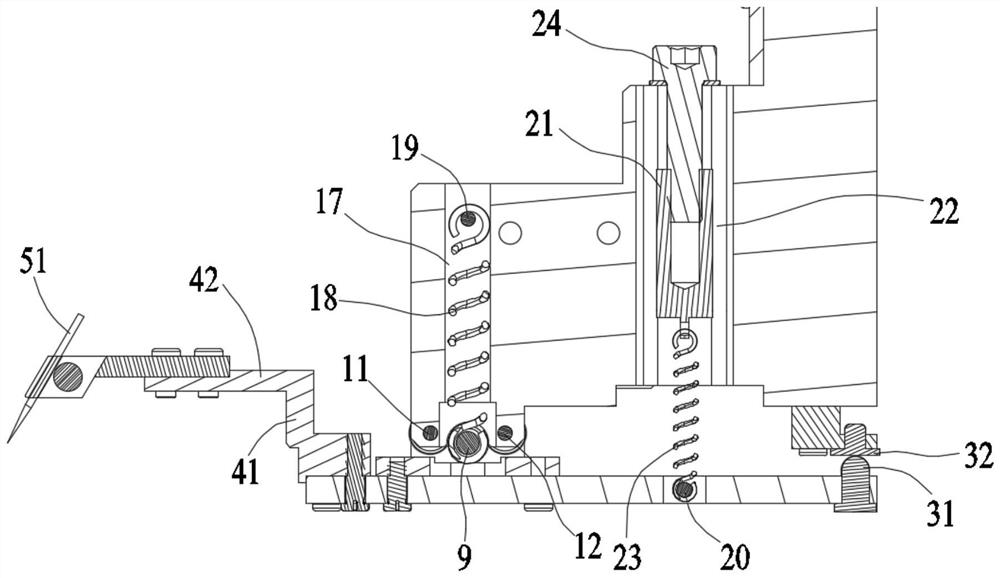

[0030]Embodiment 1: a kind of testing method that is used for laser chip, based on a testing device, described testing device comprises substrate 26, is installed on the test stand 27 of substrate 26 upper surface, is installed on the driving support 28 of substrate 26 outsides and is installed on The test probe assembly 29 on the drive bracket 28 and positioned above the test bench 27, the test probe assembly 29 includes: a body 1 connected to the drive bracket 28, a support plate 2, a probe 51 for contacting the chip to be tested and a moving point contact probe 31, a cantilever 4 is installed at one end of the support plate 2, and the moving point contact probe 31 is installed at the other end, and one side of the lower end surface of the body 1 is arranged on the upper part of the moving point contact probe 31 and corresponds to it. The static point of the contact probe 32, the end of the cantilever 4 away from the support plate 2 is fixed with a probe base 5 equipped with ...

Embodiment 2

[0040] Embodiment 2: a kind of testing method that is used for laser chip, based on a testing device, described testing device comprises substrate 26, is installed on the test platform 27 of substrate 26 upper surface, is installed on the driving support 28 of substrate 26 outsides and is installed on The test probe assembly 29 on the drive bracket 28 and positioned above the test bench 27, the test probe assembly 29 includes: a body 1 connected to the drive bracket 28, a support plate 2, a probe 51 for contacting the chip to be tested and a moving point contact probe 31, a cantilever 4 is installed at one end of the support plate 2, and the moving point contact probe 31 is installed at the other end, and one side of the lower end surface of the body 1 is arranged on the upper part of the moving point contact probe 31 and corresponds to it. The static point of the contact probe 32, the end of the cantilever 4 away from the support plate 2 is fixed with a probe base 5 equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com