Textile containing down feather

A technology of textiles and down, which is applied in the direction of textiles and papermaking, non-woven fabrics, protective clothing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

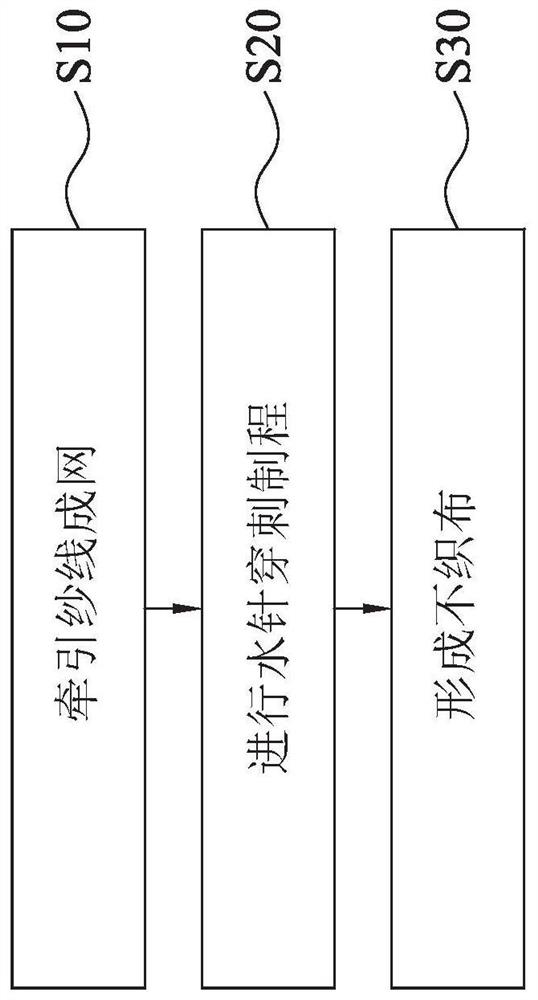

[0041] image 3 A flowchart illustrating a method for preparing a direct-spun nonwoven fabric according to an embodiment of the present disclosure. The method for preparing the direct-spun nonwoven fabric includes steps S10, S20 and S30. In step S10, the drawn yarn is formed into a web. In step S20, a water needle puncture process is performed. In step S30, a direct-spun nonwoven fabric is formed. In the following description, the above-mentioned steps will be described in detail.

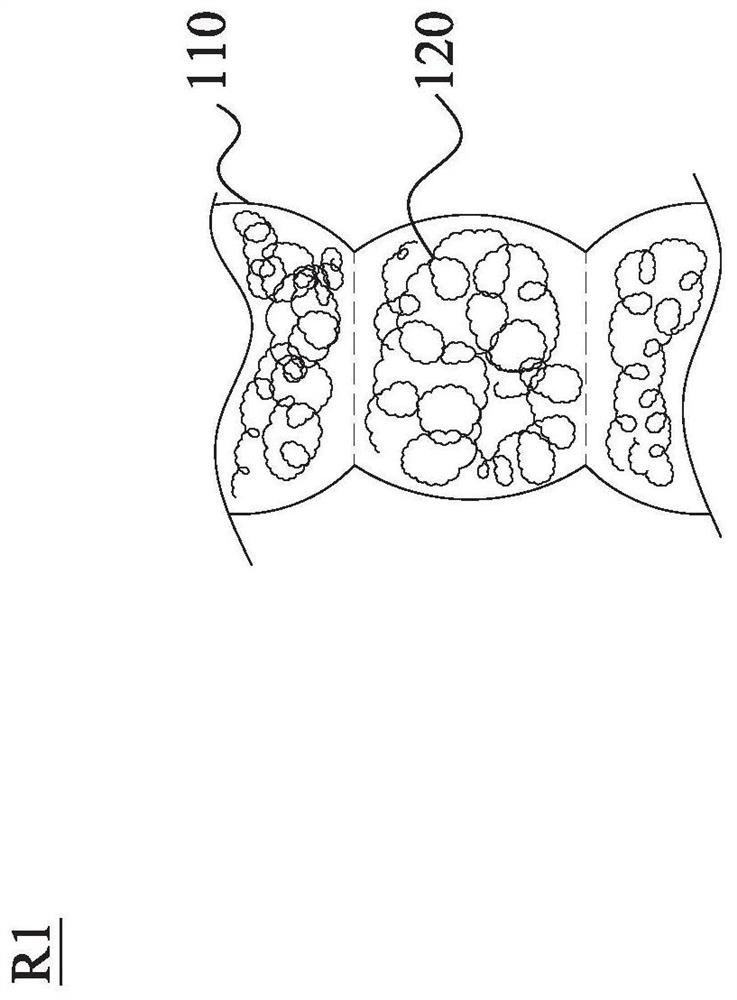

[0042] Firstly, yarn is provided, wherein the yarn material is a 32-divided composite yarn. In some embodiments, the yarn material can be selected from 32 hollow-divided composite yarns. In detail, the structure of the 32-divided composite yarn can be as follows Figure 4A to Figure 4C As shown, it shows a perspective view of a 32-split composite yarn 112 according to different embodiments of the present disclosure. Specifically, the 32-split composite yarn 112 may include nylon fibers 114 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com