Feeding device for sanitation truck garbage can

A technology of trash cans and sanitation vehicles, which is applied in the field of trash can loading, can solve the problems of long garbage can easily spill outside the collection bucket, the service life of the trash can is reduced, and the shell of the trash can is greatly worn, so as to improve the feeding efficiency, The effect of pouring thoroughly and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

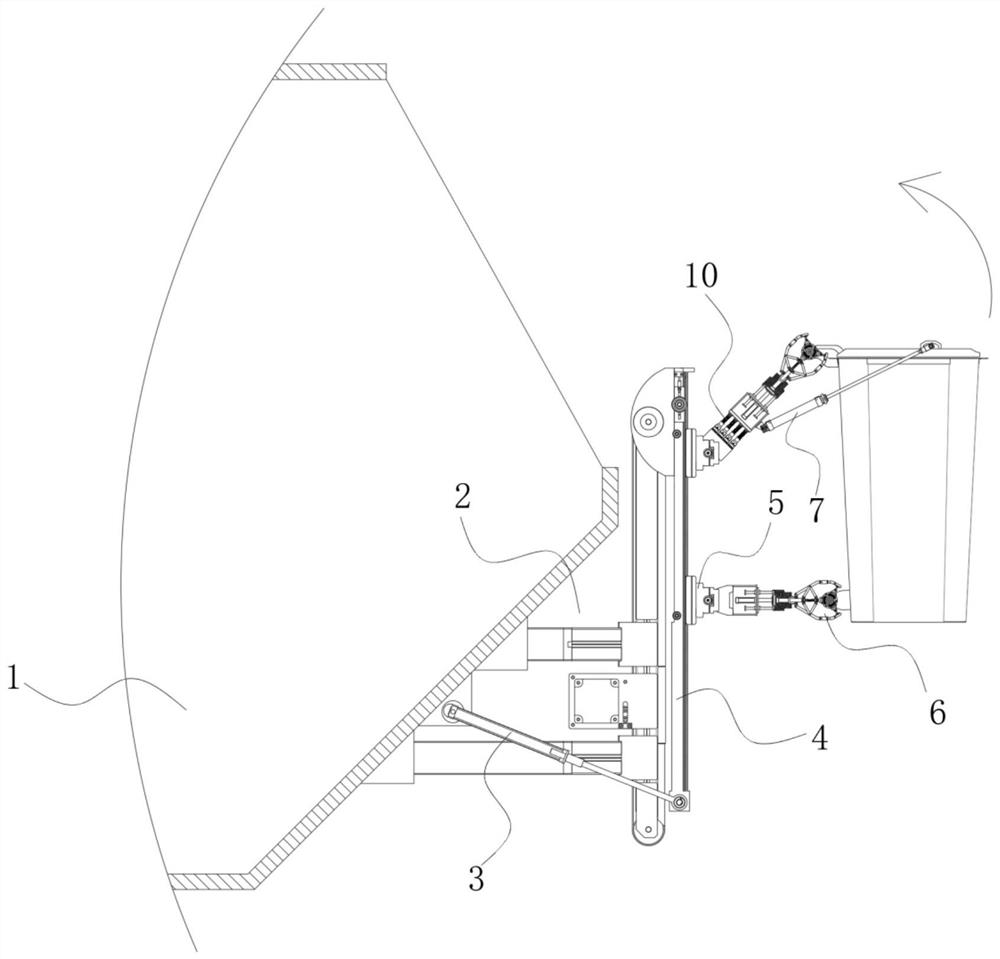

[0043] refer to figure 1 , the present invention provides a technical solution: a garbage bin feeding device for sanitation vehicles, which includes:

[0044] The rotary driving device 2 is installed on the inclined shell wall on the right side of the sanitation collection bucket 1, and its driving structure is arranged longitudinally;

[0045] Lifting frames 4, at least two groups, are arranged in parallel front and back, the upper end of which is hinged with the output end of the rotary drive device 2 through the rotating seat, so as to improve the supporting strength of the trash can and the stability during the feeding process;

[0046] The telescopic rod-3, at least two groups, is symmetrically hinged on the front and rear sides of the inclined shell wall on the right side of the sanitation collection bucket 1, and its output end is hinged to the lower end of the lifting frame 4, further, it assists the loading of the trash can and reduces the impact on the rotating drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com