A kind of high corrosion resistance super stainless steel for marine engineering equipment and its manufacturing method

A technology of marine engineering and manufacturing method, which is applied in the field of high-corrosion-resistant super stainless steel for marine engineering equipment and its manufacturing field. It can solve the problems of low-temperature toughness of unrecorded materials, low yield strength and tensile strength of duplex stainless steel plates, and achieve Good intergranular corrosion resistance, excellent corrosion resistance, stable corrosion resistance and excellent effect

Active Publication Date: 2022-07-22

ANGANG STEEL CO LTD

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

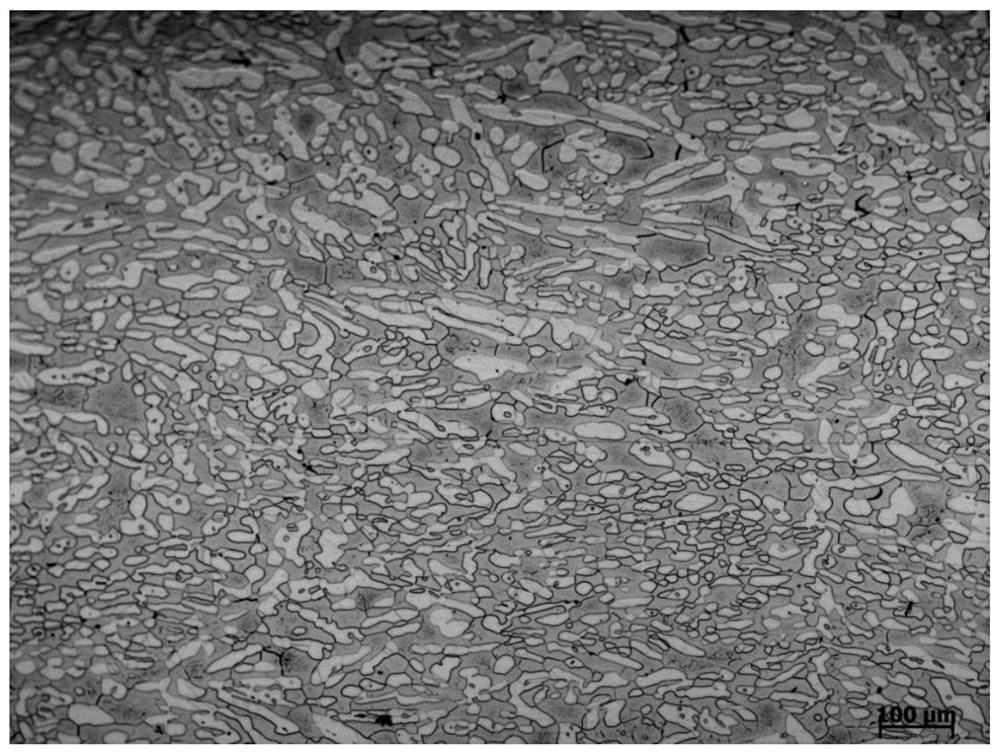

[0066] The metallographic structure of the high corrosion-resistant super stainless steel for marine engineering equipment produced in Example 1 is as follows: figure 1 As shown, it is composed of ferrite and austenite with a phase ratio of about 1:1, and the two-phase structure is fine and evenly distributed.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| brittleness temperature | aaaaa | aaaaa |

Login to View More

Abstract

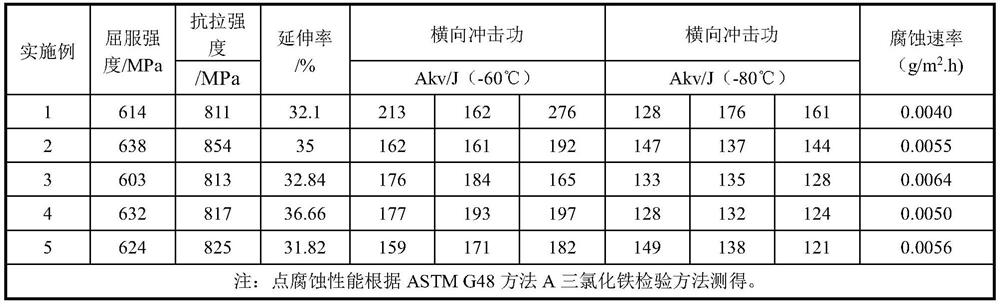

The invention relates to a high corrosion-resistant super stainless steel for marine engineering equipment. The chemical composition and mass percentage of the steel plate are as follows: C 0.001%-0.03%, Si 0.3%-0.6%, Mn 0.6%-1.5%, P≤0.02% , S≤0.002%, Cr 24%~26%, Ni 1.6%~3%, Mo 3%~4%, N 0.24%~0.32%, Cu 0.01%~0.50%, the balance is iron and inevitable impurities . The pitting resistance equivalent of the steel sheet is >40. Through reasonable composition design, special heating, rolling and solution treatment process, the super duplex stainless steel produced by the invention has high strength, high corrosion resistance and good low temperature toughness, and the steel plate has good microstructure and properties, and the performance Uniform, can meet the application in harsh and harsh marine environment.

Description

technical field [0001] The invention relates to the technical field of marine engineering steel production, in particular to a high corrosion-resistant super stainless steel for marine engineering equipment and a manufacturing method thereof. Background technique [0002] In recent years, driven by the rapid growth of the offshore engineering equipment industry, the demand for stainless steel for offshore engineering equipment has also increased year by year. Stainless steel for marine engineering equipment is usually used in harsh marine environments. In terms of corrosion resistance, in addition to ordinary marine environment corrosion resistance, it also needs to meet chemical corrosion resistance and other environments. Due to the lack of design and manufacturing experience, the stainless steel plate used in my country's marine engineering equipment still has a big gap compared with similar steel plates produced by foreign steel mills. [0003] In order to ensure the sa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/02C22C38/04C22C38/44C22C38/42C21D8/02

CPCC22C38/004C22C38/02C22C38/04C22C38/44C22C38/42C22C38/001C21D8/0226C21D8/0263C21D2211/005C21D2211/001

Inventor 王晓航严玲李文斌王华韩鹏隋松言李广龙张鹏齐祥羽李博雍

Owner ANGANG STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com