Solar photovoltaic vacuum glass tube plate type curtain wall

A vacuum glass tube and solar photovoltaic technology, applied in the field of curtain walls, can solve the problems of being unable to clean the dust of the glass curtain wall, unable to protect the outer glass wall, and inconvenient to replace the inner glass wall, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

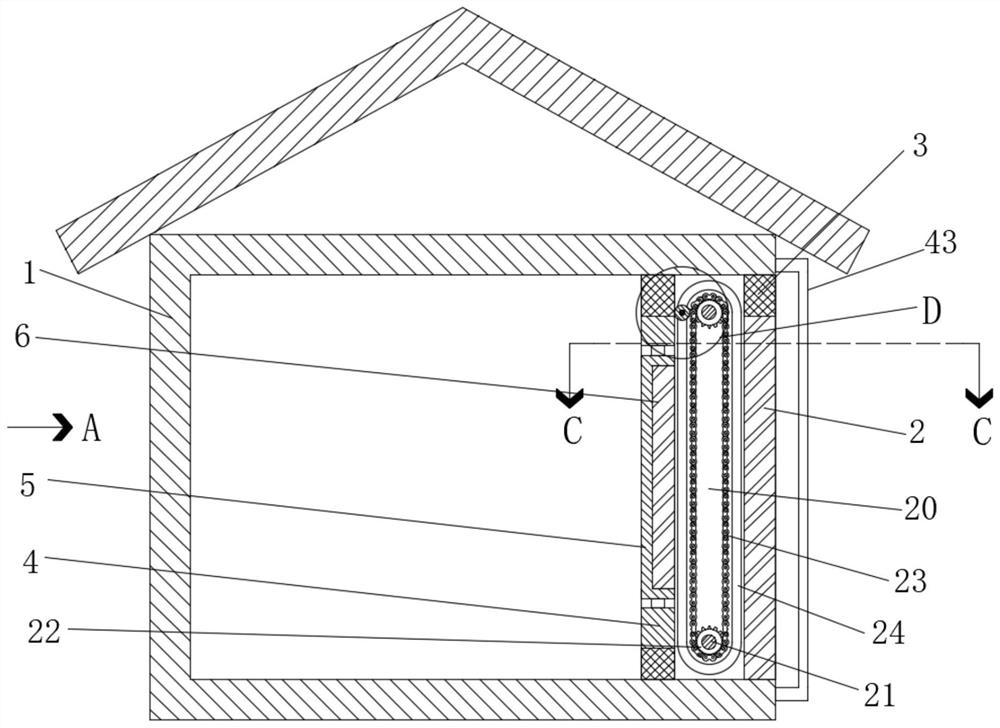

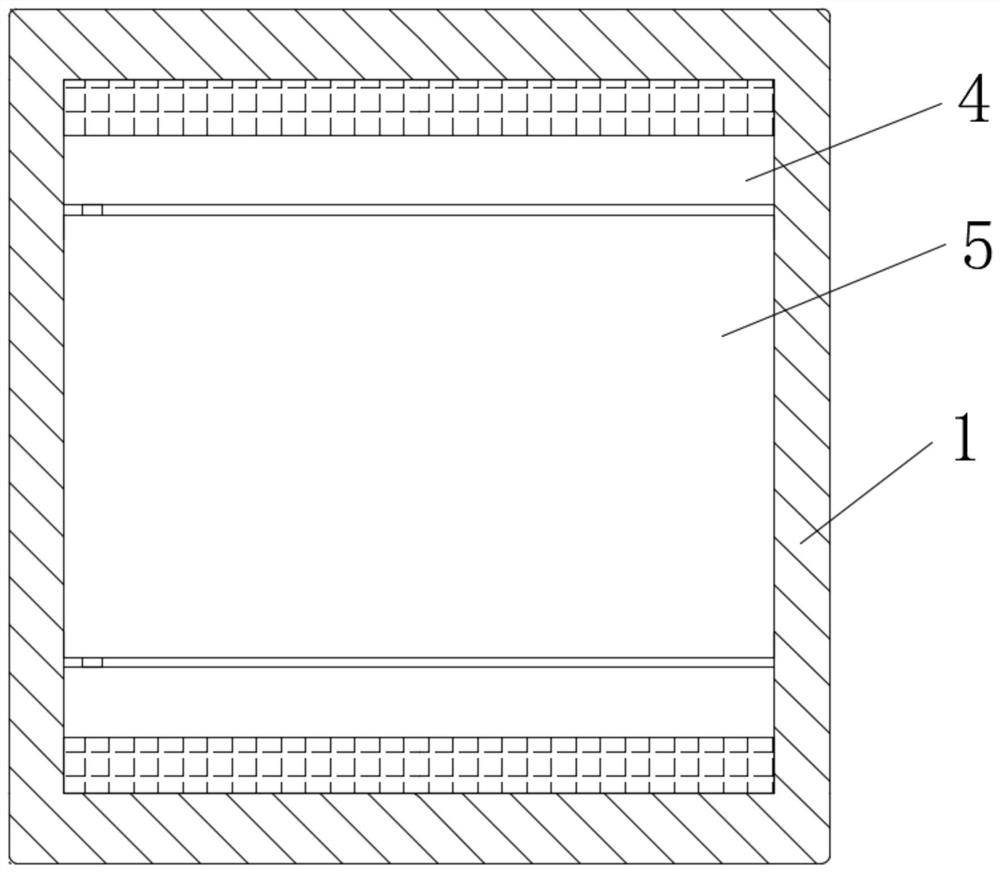

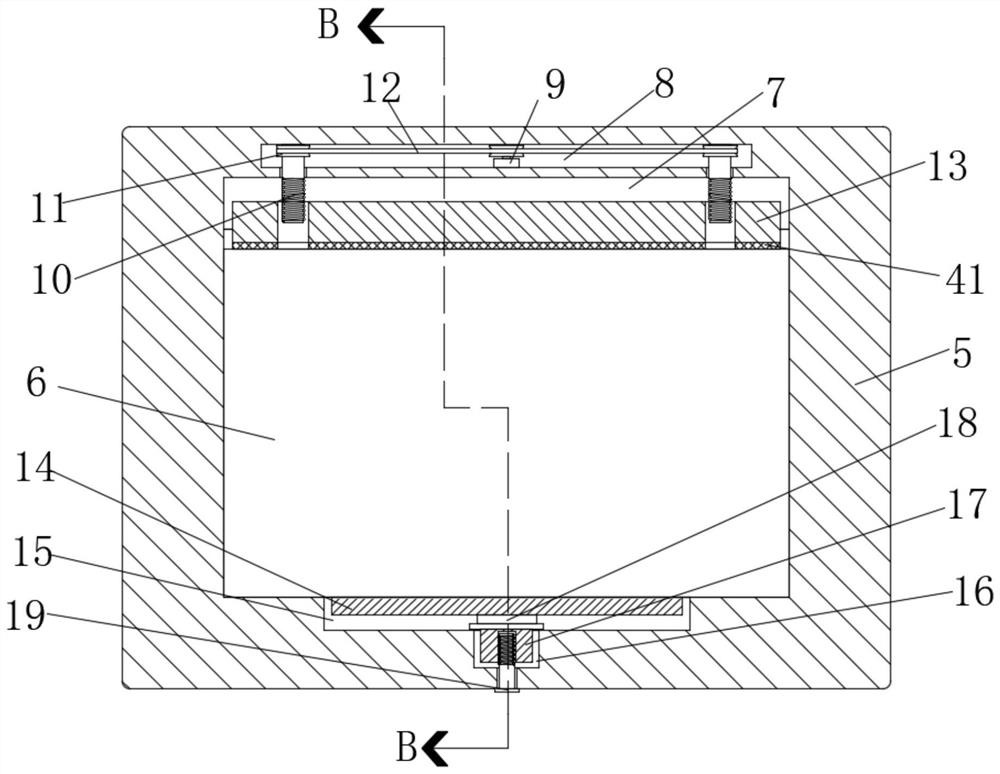

[0039] Such as Figure 1-6 The shown solar photovoltaic vacuum glass tube-sheet curtain wall includes an outer glass wall 2 arranged on one side of the house 1, the top of the outer glass wall 2 is provided with an external exhaust device 3, and the house 1 is fixedly connected with an inner partition 4 , the inner partition 4 is rotatably connected with a rotating plate 5, the rotating plate 5 is provided with a curtain wall 6, and the curtain wall 6 is composed of solar vacuum heat collecting tube plates without gaps; the rotating plate 5 is provided with a replacement assembly for replacing the curtain wall 6 , the house 1 is provided with two symmetrical connecting plates 20, and the two connecting plates 20 are located between the outer glass wall 2 and the inner partition 4, and the connecting plate 20 is provided with a connecting plate for the outer glass wall 2 and the curtain wall 6 A cleaning assembly for cleaning the inner surface.

[0040] In the present inventio...

Embodiment 2

[0052] This embodiment is a further improvement of the previous embodiment, such as Figure 1-8 As shown, a solar photovoltaic vacuum glass tube-sheet curtain wall includes an outer glass wall 2 arranged on one side of a house 1, the top of the outer glass wall 2 is provided with an external exhaust device 3, and an inner partition 4 is fixedly connected to the house 1 , the inner partition 4 is rotatably connected with a rotating plate 5, the rotating plate 5 is provided with a curtain wall 6, the rotating plate 5 is provided with a replacement assembly for replacing the curtain wall 6, and the house 1 is provided with two symmetrical connecting plates 20, And the two connecting plates 20 are located between the outer glass wall 2 and the inner partition 4 , and the connecting plates 20 are provided with a cleaning assembly for cleaning the inner surfaces of the outer glass wall 2 and the curtain wall 6 .

[0053] In the present invention, the replacement assembly includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com