Solar photovoltaic panel cleaning device and cleaning method thereof

A technology for solar photovoltaic panels and cleaning devices, which is applied to cleaning methods and utensils, cleaning methods using tools, photovoltaic power generation, etc., can solve problems such as damage to solar photovoltaic panels, cumbersome operation, large volume, etc., and achieves the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

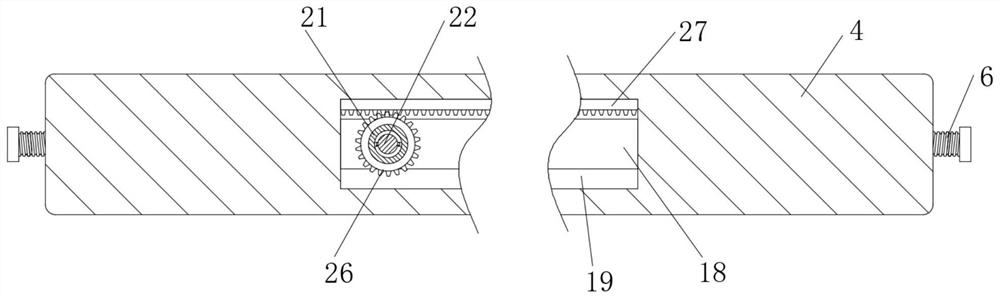

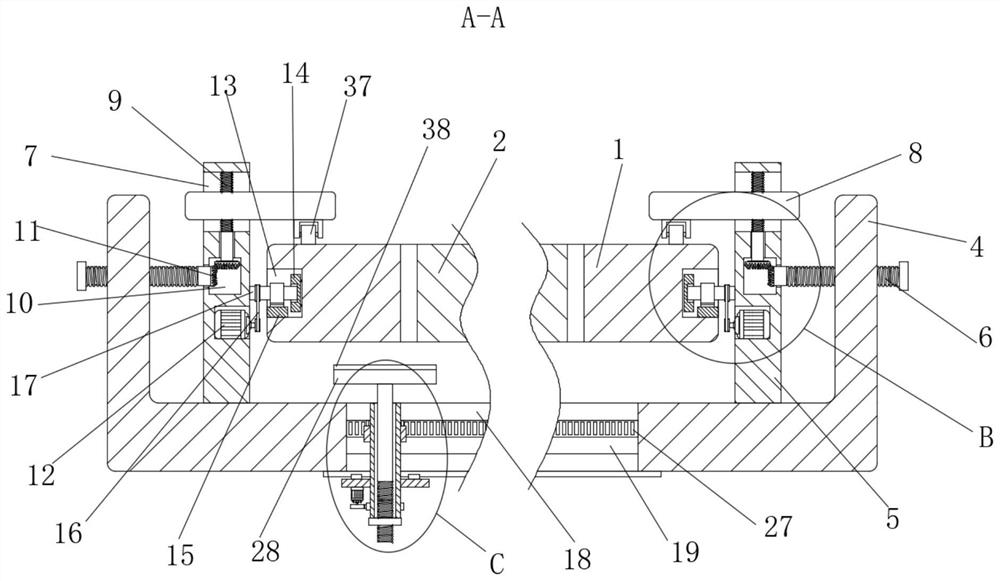

[0044] Such as Figure 1-9 A solar photovoltaic panel cleaning device shown includes a frame 1, a photovoltaic panel 2 is fixedly embedded in the frame 1, an ash discharge tank 3 is provided on one side of the frame 1, a U-shaped frame 4 is provided on one side of the frame 1, and a U-shaped frame 4 is provided on one side of the frame 1. One side of the molded frame 4 is slidingly connected with two symmetrical first slide plates 5, the U-shaped frame 4 is provided with a fixing assembly for the first slide plate 5 to clamp the frame 1, and the U-shaped frame 4 is provided with a fixing assembly for making the U-shaped frame 4. The type frame 4 moves a cleaning assembly for preliminary cleaning, and the U-shaped frame 4 is provided with a cleaning assembly for finely cleaning the frame 1 .

[0045] In the present invention, the fixing assembly includes a cavity 10 and a chute 7 arranged in the first slide plate 5 , one side of the U-shaped frame 4 is threaded through a thread...

Embodiment 2

[0057] This embodiment is a further improvement of the previous embodiment, such as Figure 1-10 As shown, a solar photovoltaic panel cleaning device includes a frame 1, a photovoltaic panel 2 is fixedly embedded in the frame 1, an ash discharge tank 3 is provided on one side of the frame 1, a U-shaped frame 4 is provided on one side of the frame 1, and a U-shaped frame 4 is provided on one side of the frame 1. One side of the molded frame 4 is slidingly connected with two symmetrical first slide plates 5, the U-shaped frame 4 is provided with a fixing assembly for the first slide plate 5 to clamp the frame 1, and the U-shaped frame 4 is provided with a fixing assembly for making the U-shaped frame 4. The type frame 4 moves a cleaning assembly for preliminary cleaning, and the U-shaped frame 4 is provided with a cleaning assembly for finely cleaning the frame 1 .

[0058] In the present invention, the fixing assembly includes a cavity 10 and a chute 7 arranged in the first sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com