Automatic correction method for low-voltage shunt monitoring equipment

A monitoring equipment and automatic calibration technology, applied in the low-voltage electrical field, can solve the problems of low deployment rate of inspection personnel, occupation, multi-manpower and time costs, and save manpower and time costs, save labor costs, and improve maintenance efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

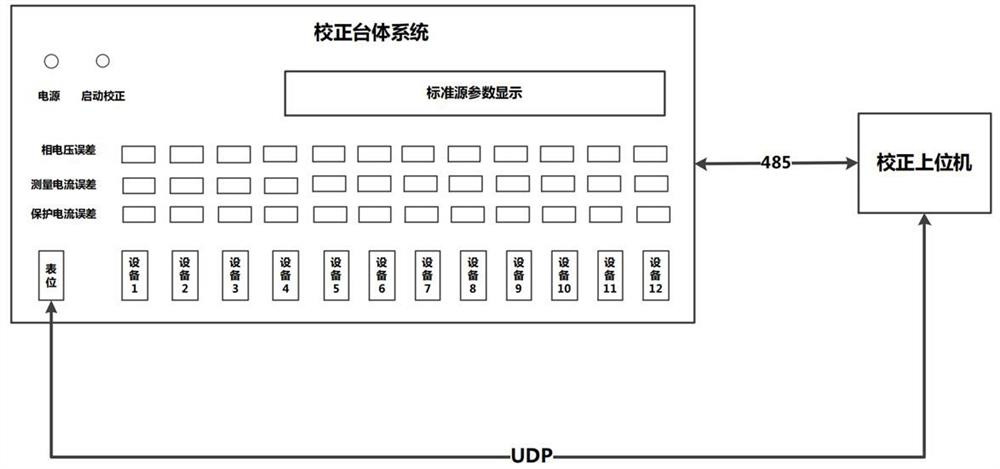

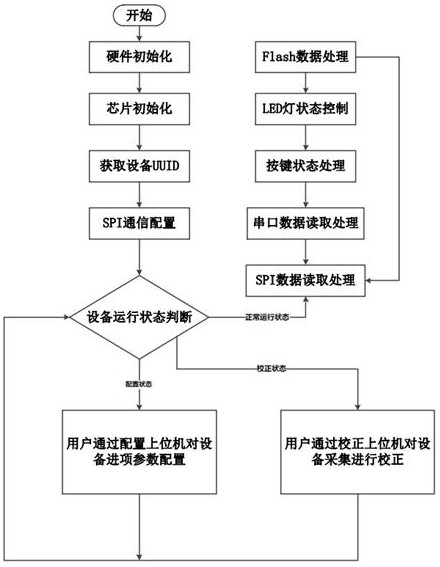

[0032] Attached below Figure 1-5 The present invention is described in detail. The implementation of the present invention needs to cooperate with the correction host computer software provided by the outside world and the calibration platform system that provides the standard source. The present invention implements the low-voltage shunt monitoring equipment, calibration host computer software, and calibration based on the network communication protocol. Information exchange between platform and body systems, such as figure 1 shown.

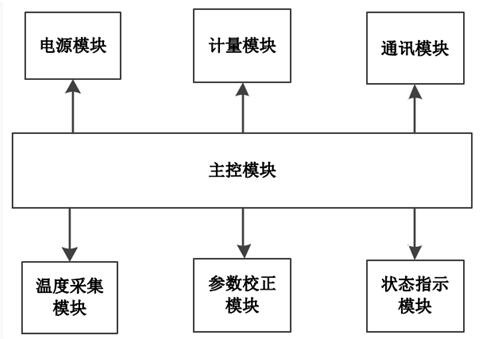

[0033] Such as figure 2 As shown, the control circuit includes a main control module, a power module, a metering module, a communication module, a temperature acquisition module and a status indication module; the metering module is connected to the main control module through an SPI interface, and the metering module has a built-in metering chip. The main control module is then connected to the communication module, temperature acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com