Composite selective laser melting device for printing supporting structure and forming method

A technology of laser selective melting and support structure, which is applied to the improvement of process efficiency, additive manufacturing, and energy efficiency improvement. It can solve the problems of difficult separation of support structure and workpiece, damage to the workpiece, and less innovative research and design. It achieves convenient recycling, strong bond effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] It should be noted that in the present invention, the orientations or positional relationships indicated by terms such as "upper", "lower", "left", "right", etc. are based on the orientation or positional relationships shown in the drawings, and are only for the convenience of description The relational words determined by the structural relationship of the various components in the present invention do not specifically refer to any component in the present invention, and should not be construed as limiting the present invention.

[0030] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

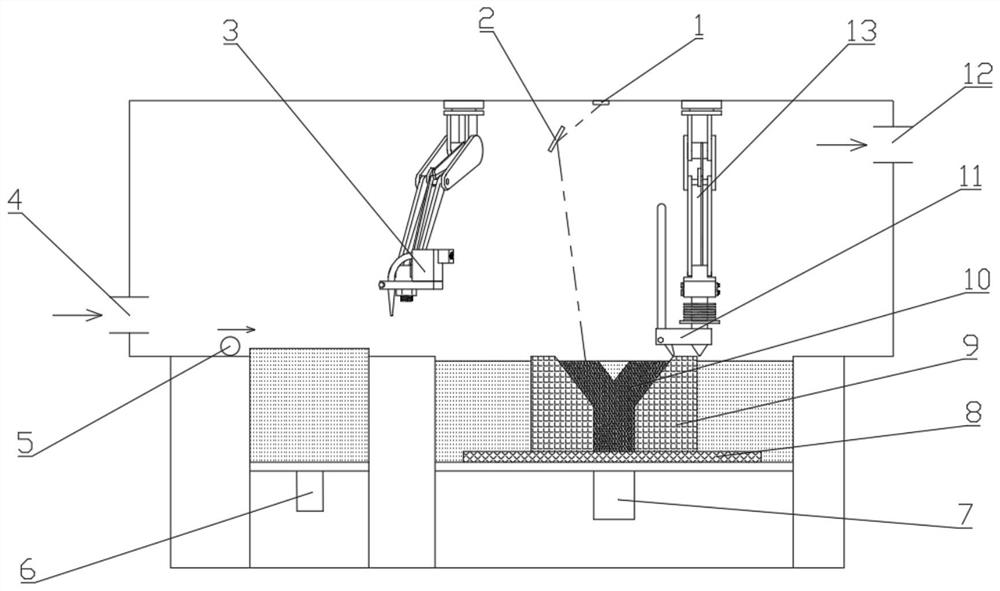

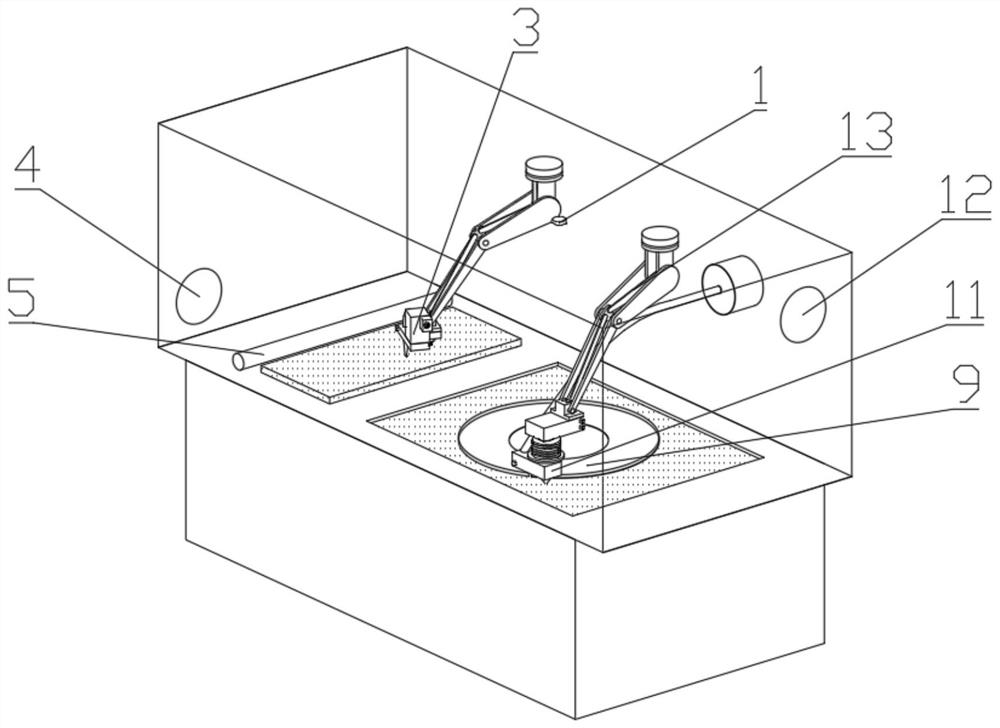

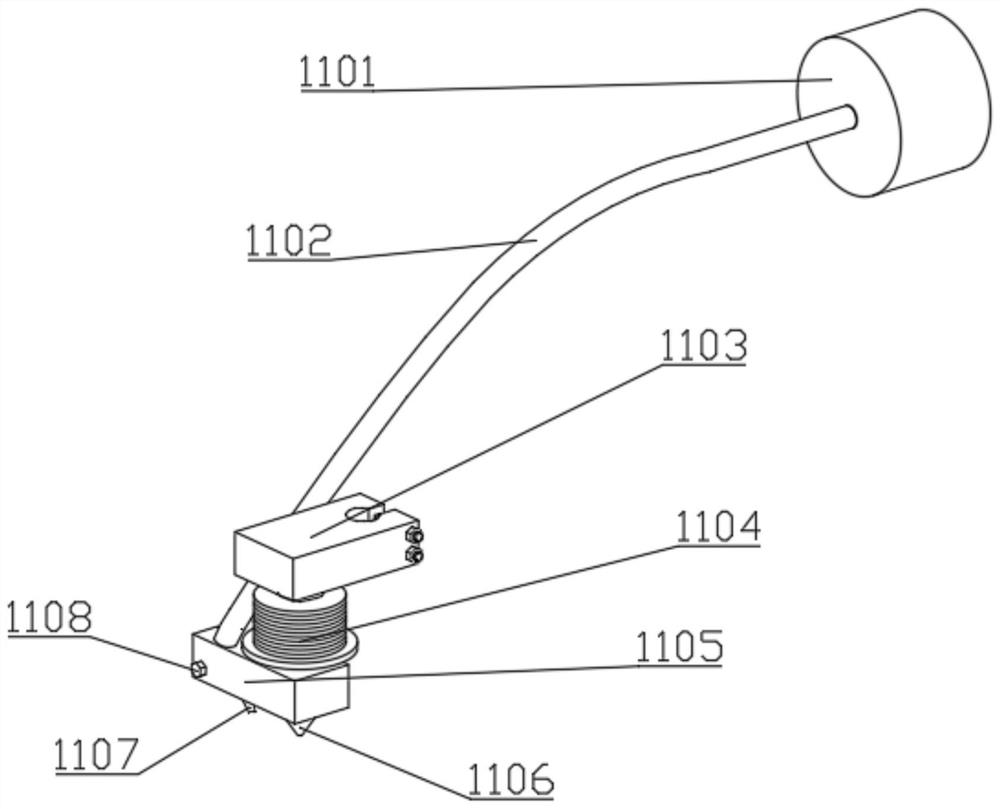

[0031] Such as Figure 1-5 As shown, a compound laser selective melting device and forming method for printing support structures is realized by the present invention through the following technical solutions: a compound laser selective melting device for printing support structures, consisting of laser emitter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap