Drill bit and mechanical arm of end-mill type machine

A technology of mechanical arms and gong knives, which is applied in the direction of manipulators, claw arms, twist drills, etc., can solve the problems of inconvenient tool replacement, etc., and achieve the effect of inconvenient replacement and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

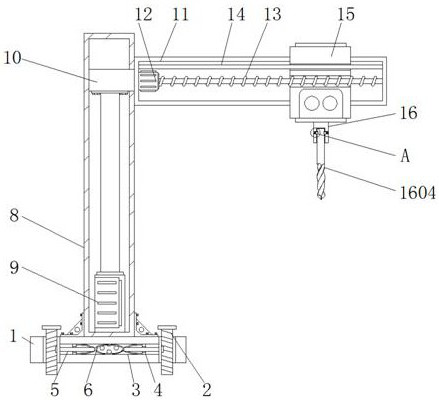

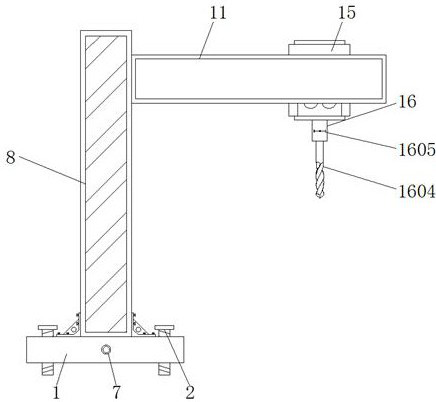

[0022] Example 1: See Figure 1-5 , the mechanical arm of the drilling nozzle and gong-knife machine, including a base 1, a slider 15 and a fixed block 1601, a second support plate 8 is installed above the base 1, and a hydraulic cylinder 9 is installed under the second support plate 8 , the top of the hydraulic cylinder 9 is equipped with a connecting plate 10, and the right side of the outer wall of the connecting plate 10 is equipped with a sliding plate 11, the inside of the sliding plate 11 is equipped with a motor 12, and the external right side of the motor 12 is equipped with a threaded column 13, the screw thread A screw rod 14 is installed above the column 13 , and a slider 15 is installed outside the screw rod 14 , and a replacement structure 16 is installed below the slider 15 .

[0023] The replacement structure 16 is made up of a fixed block 1601, a chute 1602, a second clamping plate 1603, a cutter 1604, a receiving plate 1605, a steel wire 1606 and a rotating r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com