Assembling mechanism of building scaffold

An assembly mechanism and building construction technology, which is applied in the direction of workpiece clamping devices, manufacturing tools, mechanical equipment, etc., can solve the problems of uneven base, long time consumption, and high labor intensity of workers, so as to reduce installation errors and flatness errors , Reduce the cost of manual adjustment, and improve the efficiency of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

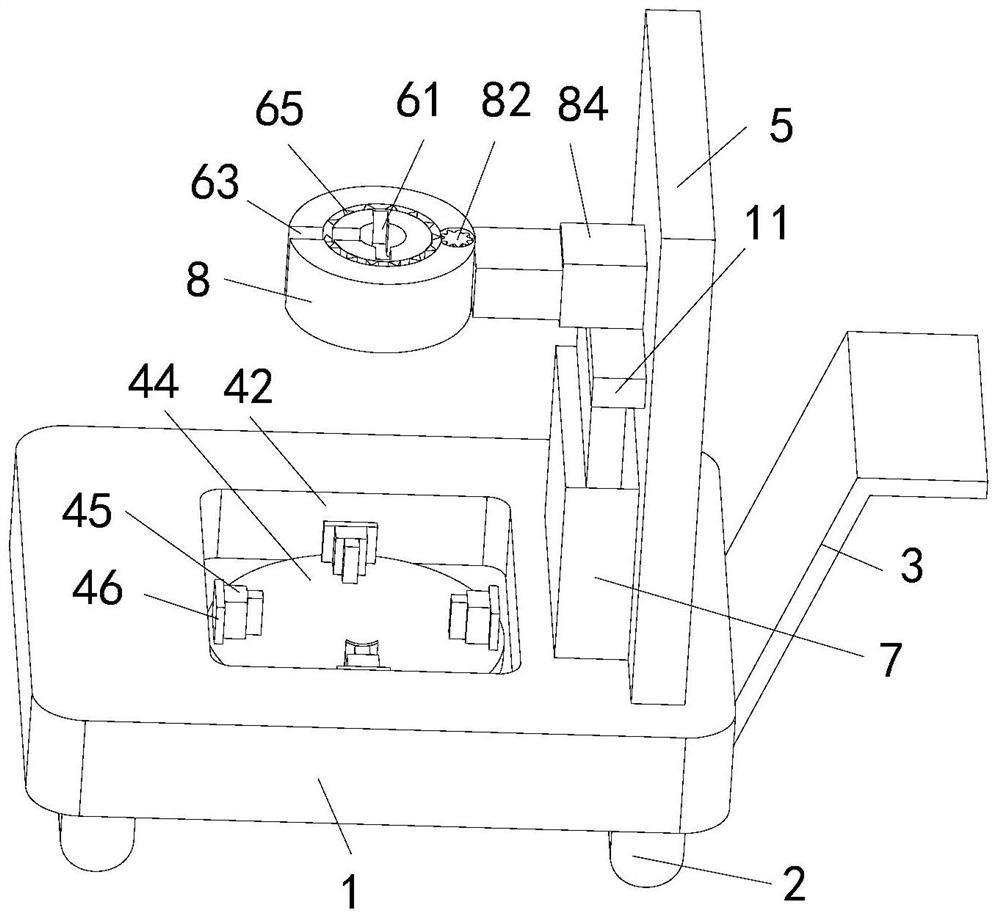

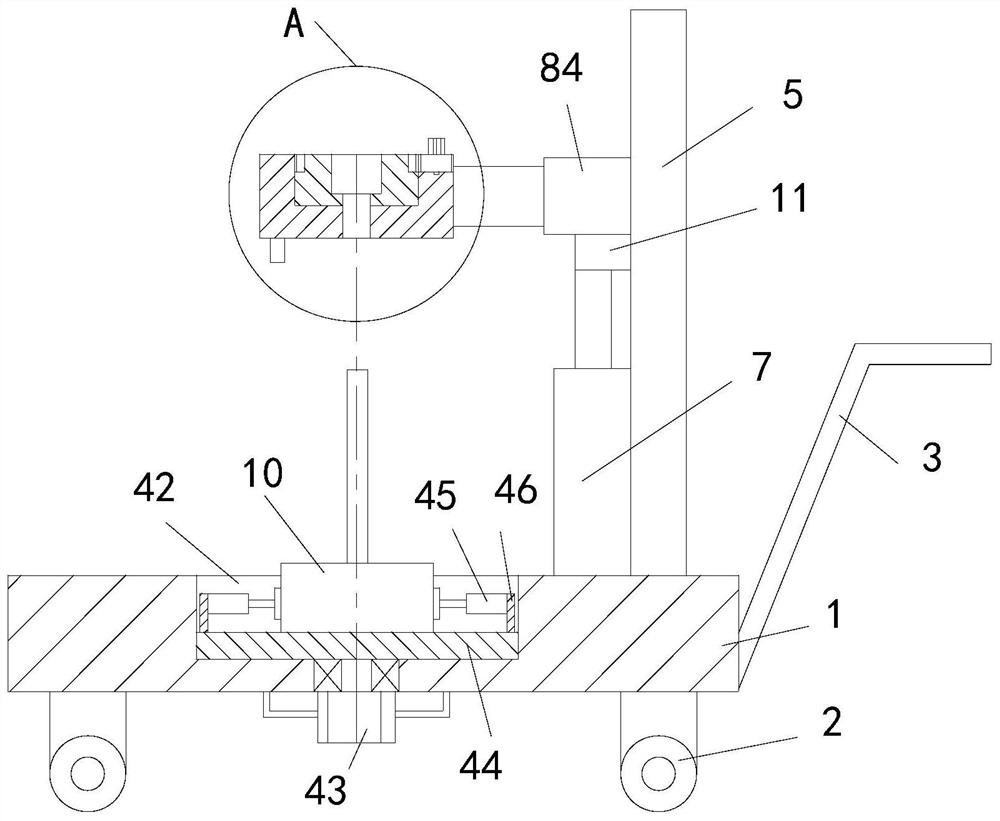

[0034] An assembly mechanism for a building construction frame, comprising a base body 1; a rotating mechanism 4 is arranged on the base body 1, an armrest 3 is arranged on one side of the base body 1, a walking wheel 2 to be self-locking is arranged under the base body 1, and the handrail 3. It is convenient for workers to push, and the walking wheel 2 is convenient for the assembly mechanism to move freely; one side of the seat body 1 is also provided with a frame body 5, and the frame body 5 is provided with a pressing block 6;

[0035] Further, the rotating mechanism 4 includes a clamping piece 41, a rotating groove 42, a rotating motor 43 and a rotating plate 44, the base body 1 is provided with a rotating groove 42, and a rotating motor 43 is installed at the bottom of the rotating groove 42, The top of the rotary motor 43 is connected with a rotating plate 44, the top of the rotating plate 44 is provided with a clamping piece 41, the clamping piece 41 is arranged in an a...

Embodiment 2

[0040] On the basis of Embodiment 1, the present invention adds a mechanism that can independently adjust the adjustable base 10; details are as follows:

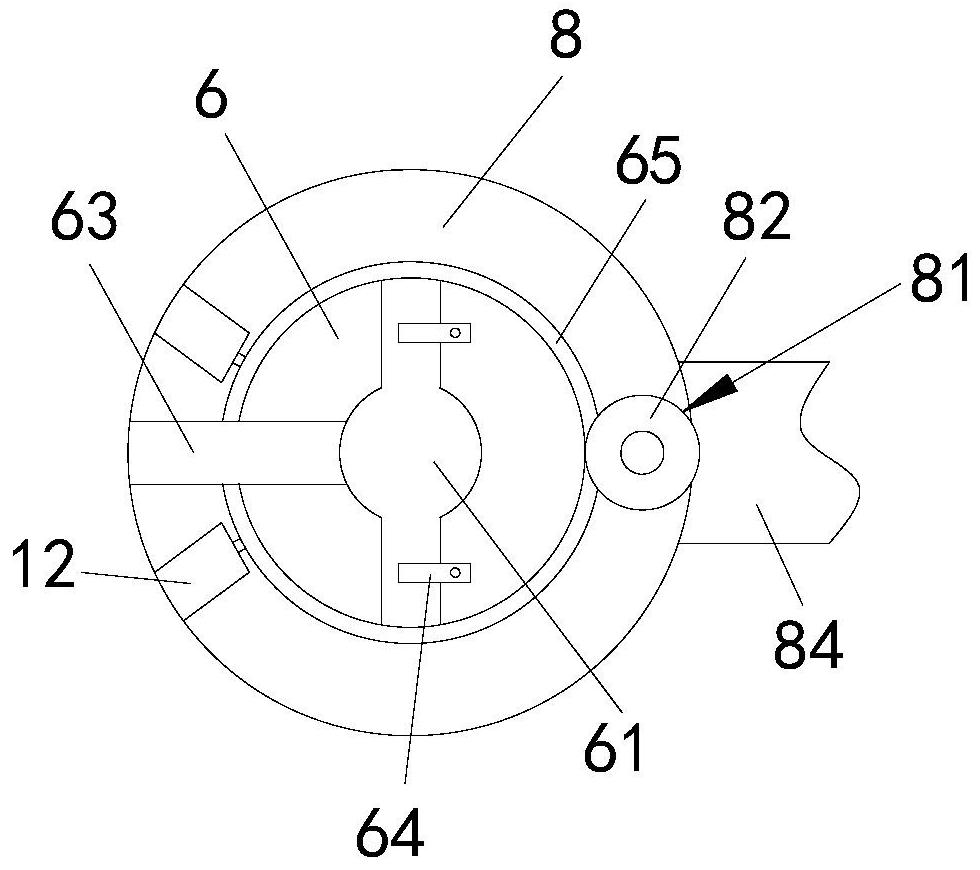

[0041] Further, an outer ring seat 8 is provided on the outside of the pressing block 6, the pressing block 6 is set in a circular shape, a groove is provided on the upper surface of the outer ring seat 8, and the pressing block 6 is located in the groove, The exit groove 63 of the briquetting block 6 penetrates to the outer ring seat 8, and the end of the lifting cylinder 7 is provided with a mounting seat 11, and a telescopic cylinder 84 is arranged in the mounting seat 11, and the telescopic cylinder 84 and the outer ring seat 8. The outer surface is fixedly connected; the outer surface of the pressure block 6 is provided with an external tooth portion 65, and the side of the outer ring seat 8 opposite to the push-out groove is provided with a wheel groove 81, and a gear 82 is installed in the wheel groove 81 for rotation...

Embodiment 3

[0046] The present invention has added the lubricating mechanism on the basis of embodiment two; Specifically as follows:

[0047] The gap between the pressure block 6 and the groove is matched, and the upper surface of the outer ring seat 8 is provided with a number of oil storage chambers 12, and the oil outlets of the oil storage chambers 12 are aligned with the gap between the pressure block 6 and the groove. A plurality of oil passages 13 are arranged on the lower surface of the pressure block 6, and an installation ring 16 is arranged on the inner wall of the through hole 62 of the outer ring seat 8, and an oil guide plate 14 is arranged inside the installation ring 16, and the oil guide plate 14 is spirally distributed , the end of the oil guide plate 14 is curled upwards to form an ear-shaped descaling body 15 , one end of the oil channel 13 communicates with the gap, and the other end faces the oil guide plate 14 .

[0048] By setting the oil storage chamber 12, the o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap