A steel structure manufacturing and processing system

A processing system and steel structure technology, applied in the field of steel structure, can solve the problems of loose trapezoidal plate, insufficient butt joint, unable to adjust the splint, etc., to achieve the effect of precise adjustment and increase the production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention can be implemented in many different ways that are predetermined and covered by the claims.

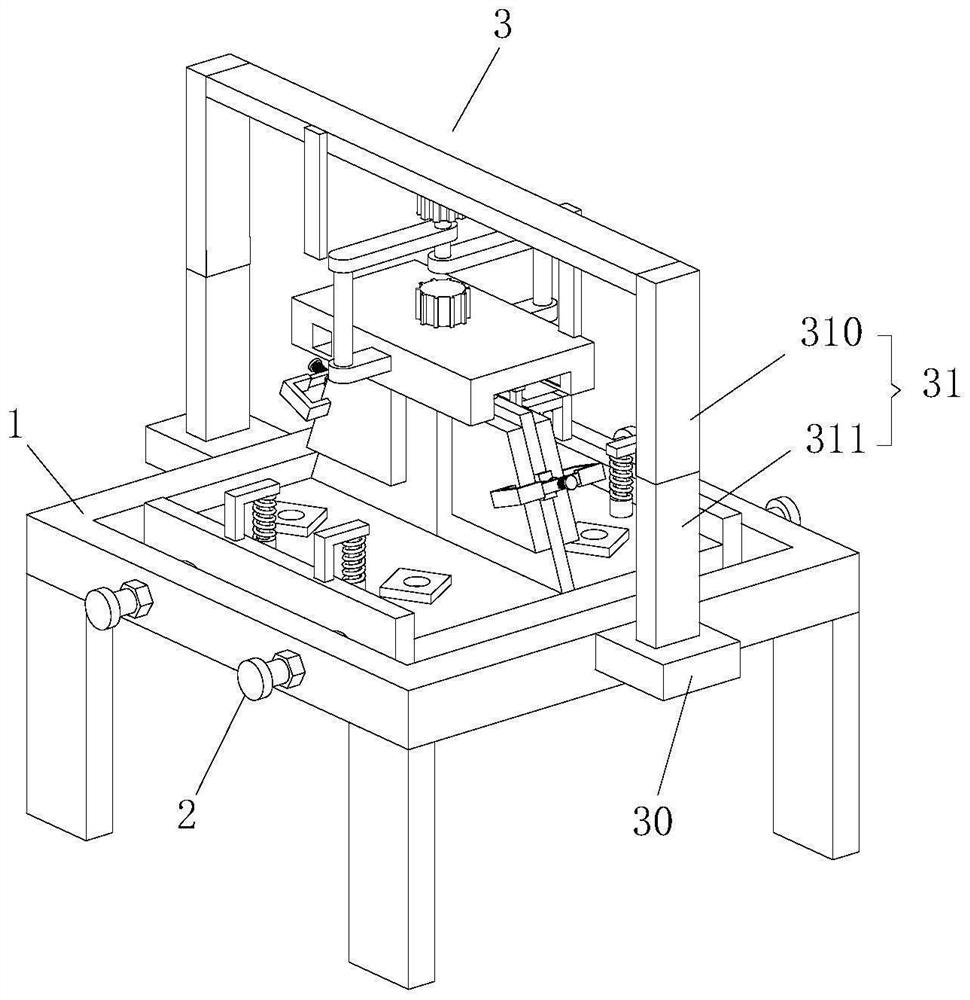

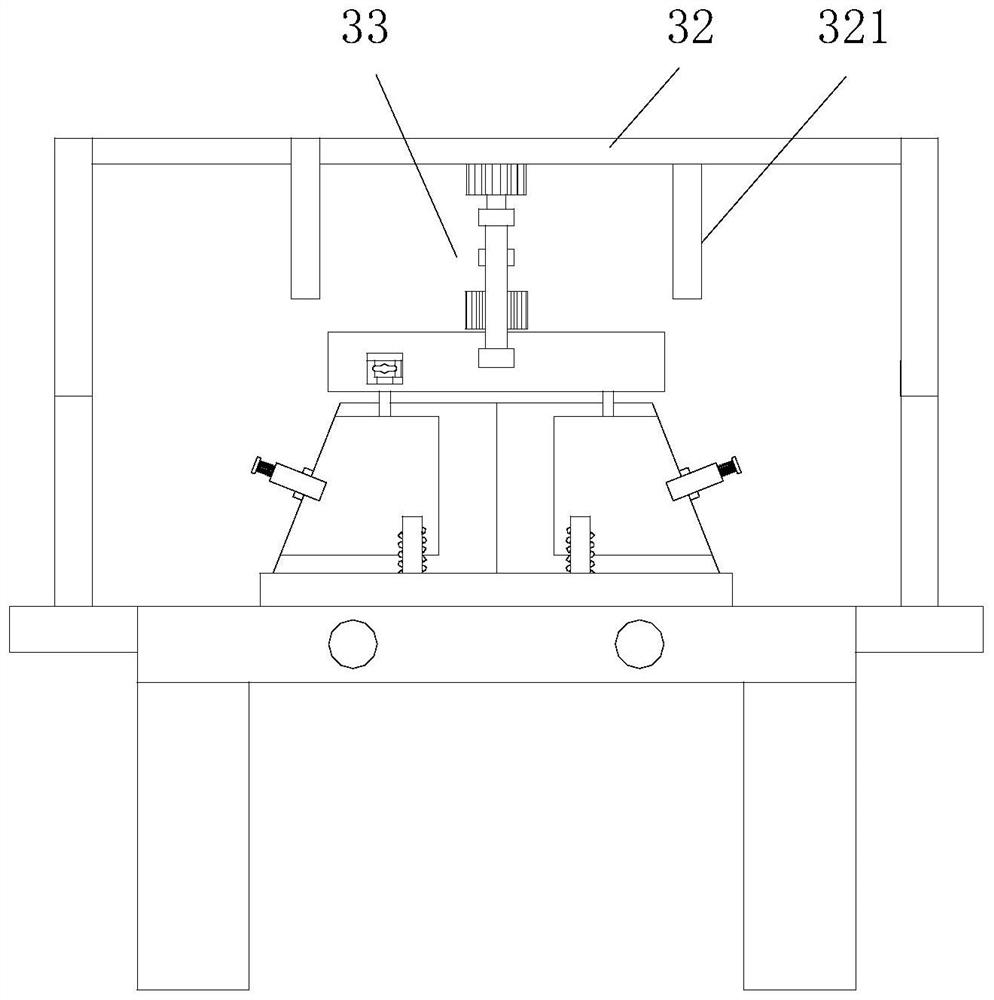

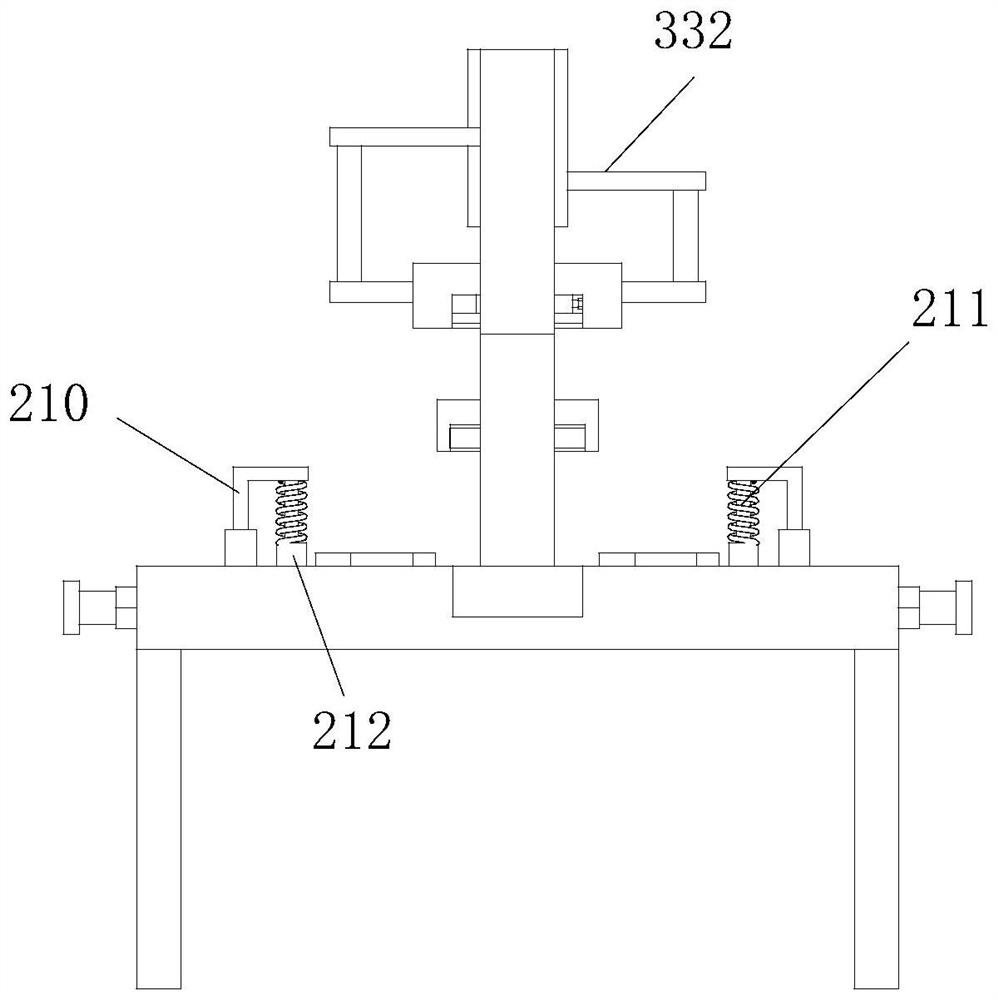

[0038] Such as Figure 1 to Figure 11 As shown, a steel structure manufacturing and processing system includes a workbench 1, a limit device 2 and a clamping alignment device 3. The workbench 1 is connected to the existing ground, and the limit device 2 is arranged on the workbench 1. A clamping alignment device 3 is arranged above the limiting device 2 .

[0039] The limiting device 2 includes a storage slot 20, a limiting plate 21, a limiting bolt 22 and a limiting spring 23. The storage slot 20 is set on the upper surface of the workbench 1, and the front and rear symmetrical sliding connections of the limiting plate are connected in the storage slot 20. 21. The end of the limit plate 21 close to the inner wall of the workbench ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com