Welding forming system of electric power fitting grading and shielding ring

A welding forming and power fitting technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of inability to adjust the welding point, low welding efficiency, material deviation, etc., to improve flexibility and practicality performance, improve welding efficiency, and avoid the effect of offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

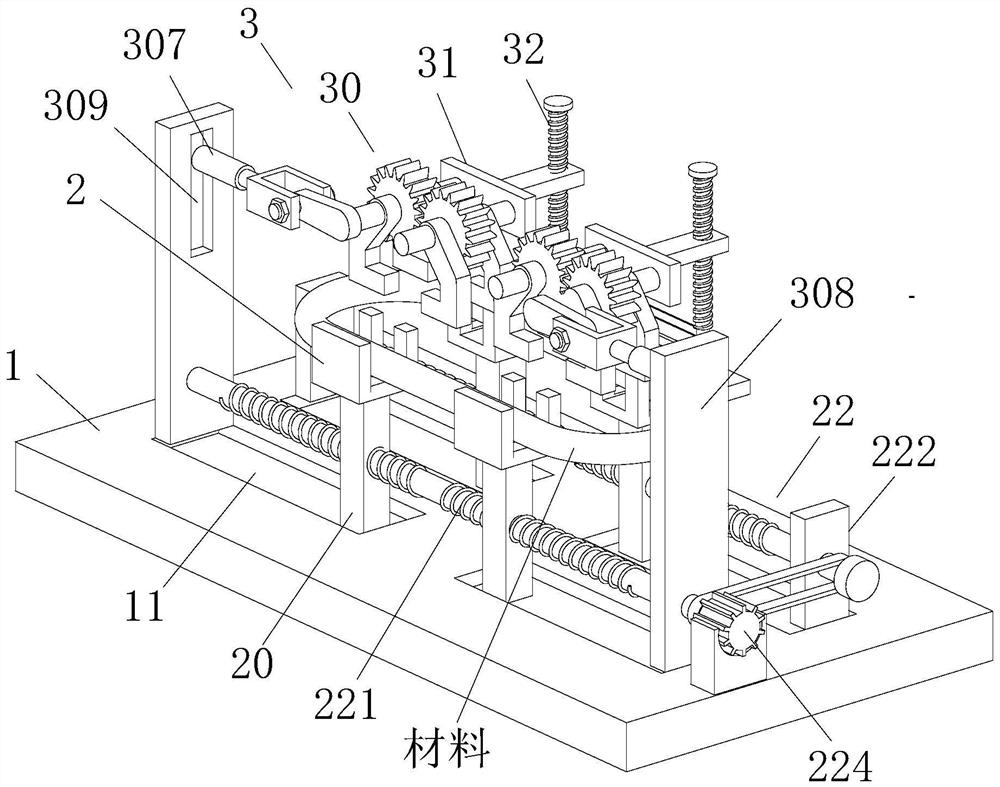

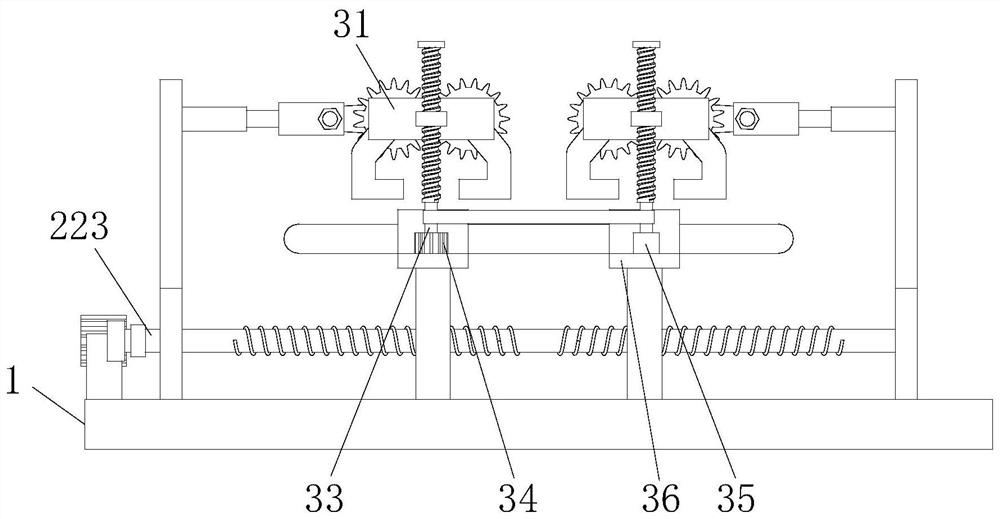

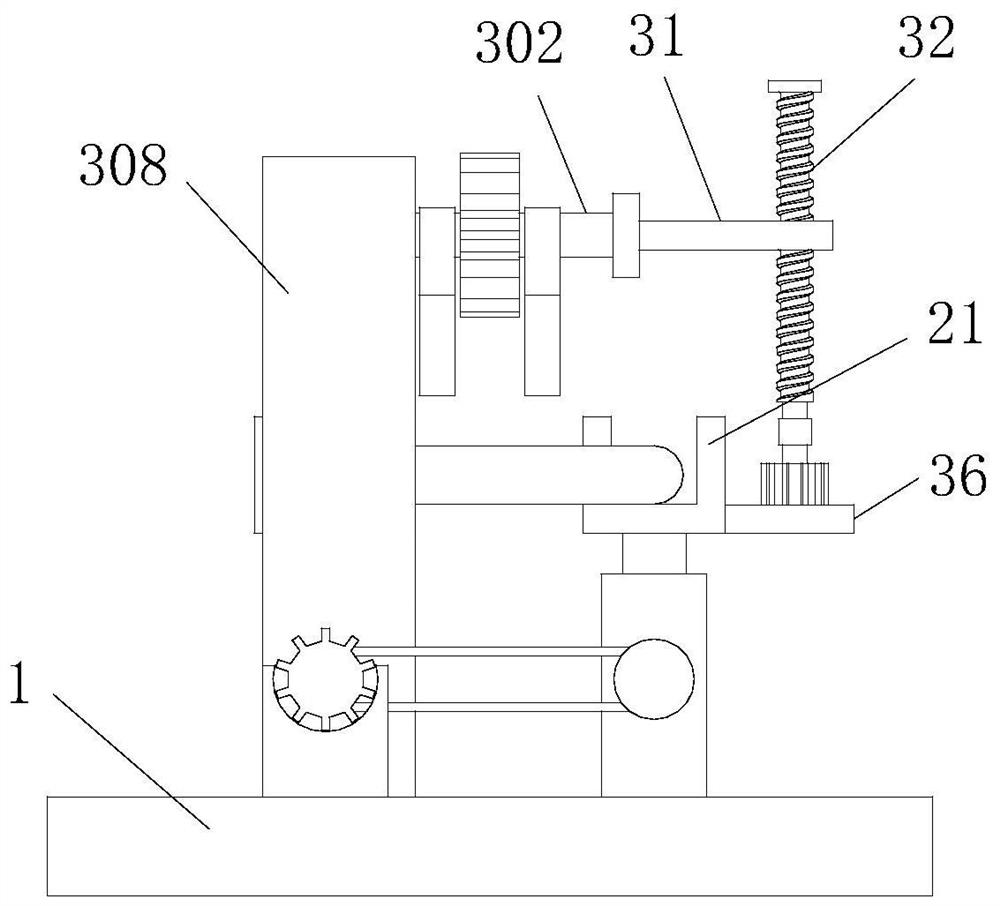

[0028] Such as Figure 1 to Figure 7 As shown, a welding and forming system for voltage equalizing shielding rings of power fittings includes a base 1, a positioning mechanism 2 and a clamping alignment mechanism 3. The lower end surface of the base 1 is connected to the existing ground, and the upper end of the base 1 is installed with The positioning mechanism 2 is provided with a clamping alignment mechanism 3 above the positioning mechanism 2 .

[0029] The upper end surface of the base 1 is symmetrically provided with chute 11, the chute 11 is symmetrically arranged front and back, the lower end of the support plate 308 and the lower end of the support rod 20 are connected to the base 1 in the chute 11 by sliding fit, By providing the slide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap