Ceramic tile cutting equipment capable of conveniently collecting excess materials and used for construction site

A technology for construction sites and cutting equipment, applied in stone processing equipment, work accessories, manufacturing tools, etc., can solve the problems of unaligned tiles, deviation of cutting positions, and labor consumption, so as to facilitate adjustment of the cutting position of tiles and facilitate collection. , Auxiliary to correct the effect of tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

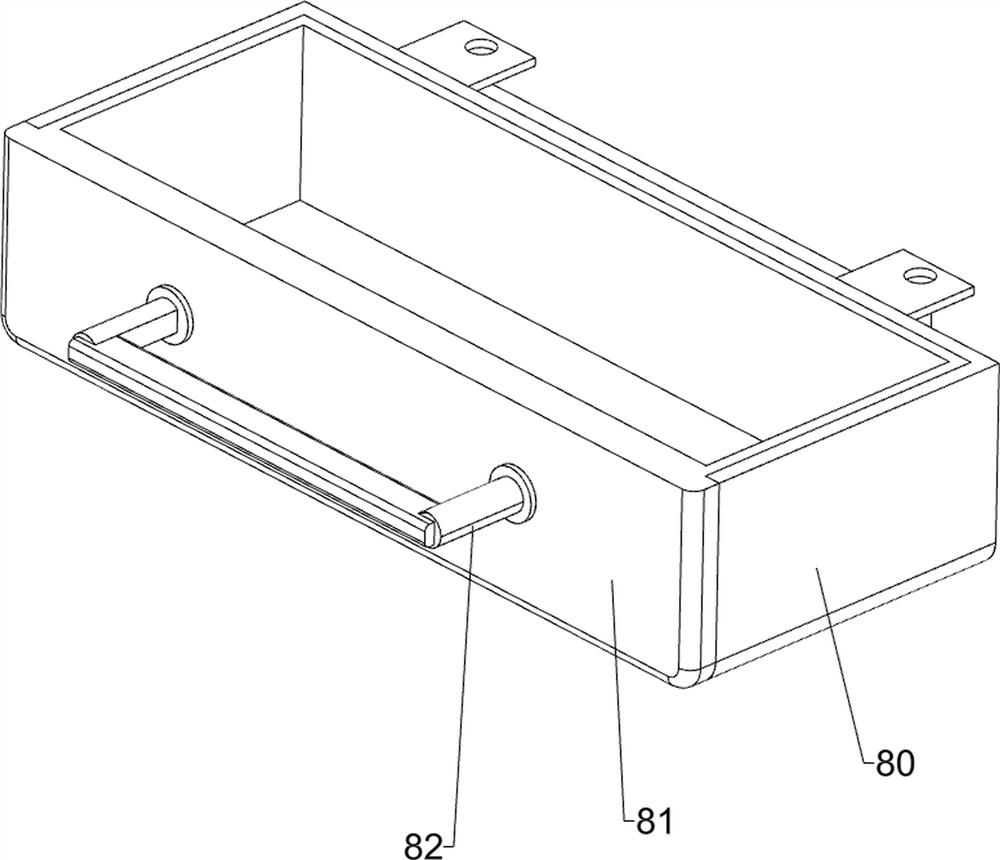

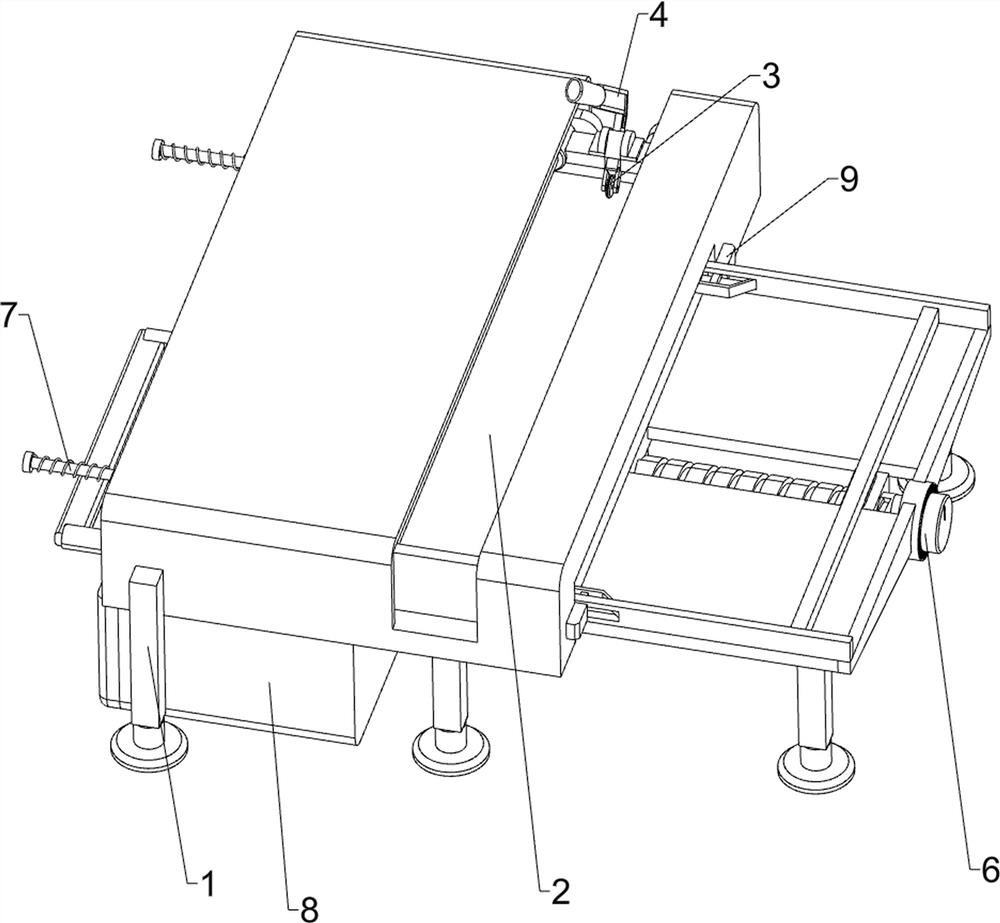

[0027] Such as Figure 1 ~ Figure 4 As shown, this embodiment discloses a ceramic tile cutting device for construction sites that is convenient for collecting residual materials, including a support rod 1, a housing 2, a diamond 3, a cutting mechanism 4 and a clamping mechanism 5, and the lower part of the housing 2 is opened on the left side. There are openings, three supporting rods 1 are connected to the front and rear sides of the lower part of the housing 2, a cutting mechanism 4 is provided in the middle of the housing 2, a diamond 3 is provided on the cutting mechanism 4, and a clip is provided between the inside of the housing 2 and the cutting mechanism 4. Tight mechanism5.

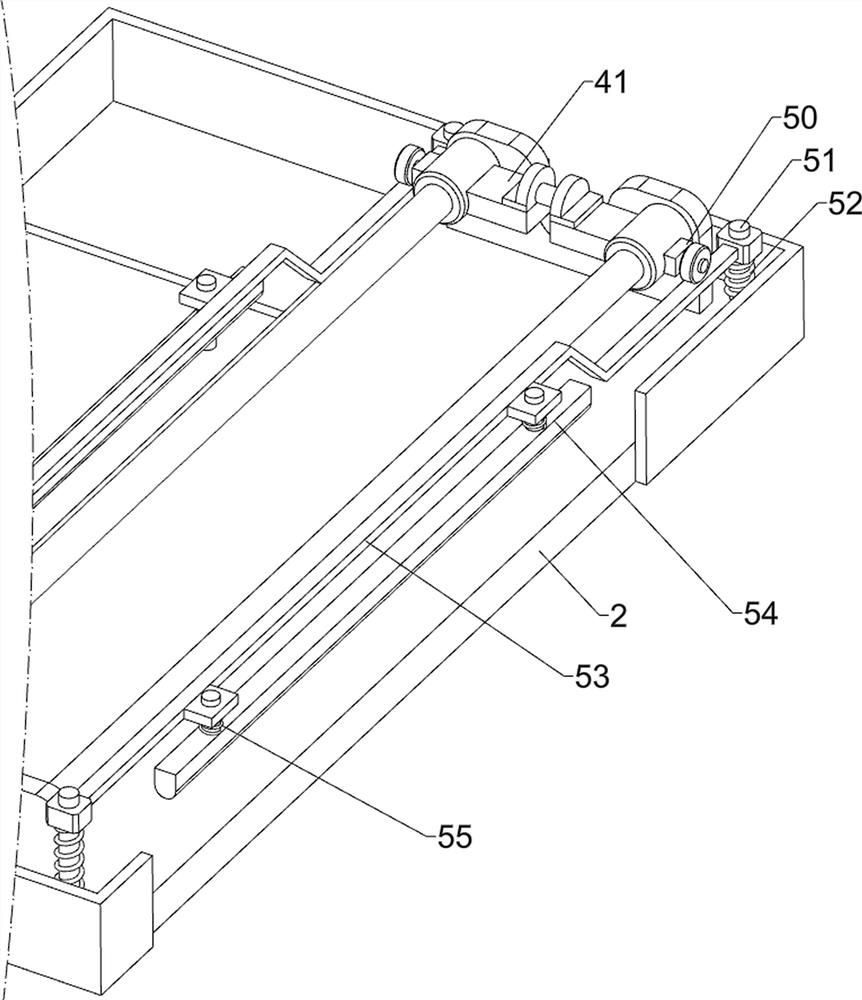

[0028] The cutting mechanism 4 includes a fixed seat 40, a first guide rod 41, a slider 42 and a handle 43. The front and rear sides of the middle part of the housing 2 are connected with a fixed seat 40, and the left and right symmetrical connections between the fixed seats 40 are connected with...

Embodiment 2

[0032] Such as figure 1 , figure 2 , Figure 5 ~ Figure 8 As shown, in some embodiments, an adjustment assembly 6 is also included. The adjustment assembly 6 includes a mounting block 60, a knob 61, a screw rod 62, a ball 63, a third spring 64 and a push rod 65, and the right side of the housing 2 is connected in the middle There is a mounting block 60, and the right side of the mounting block 60 is symmetrically opened with slotted holes up and down. A screw 62 is rotatably connected between the inner side of the mounting block 60 and the housing 2, and a knob 61 is connected to the right side of the screw rod 62, and the middle left side of the knob 61 is symmetrical up and down. The ball 63 is slidingly connected, the ball 63 cooperates with the mounting block 60, the third spring 64 is connected between the ball 63 and the knob 61, and the screw rod 62 is threadedly connected with a push rod 65.

[0033]When the user wants to adjust the tile cutting position, turn the k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com