Hardware cutting equipment

A technology of cutting equipment and hardware, which is applied in the field of hardware processing, can solve the problems of difficult adjustment of cutting position and unstable cutting, and achieve the effect of easy cutting position, stable cutting and adjustable cutting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

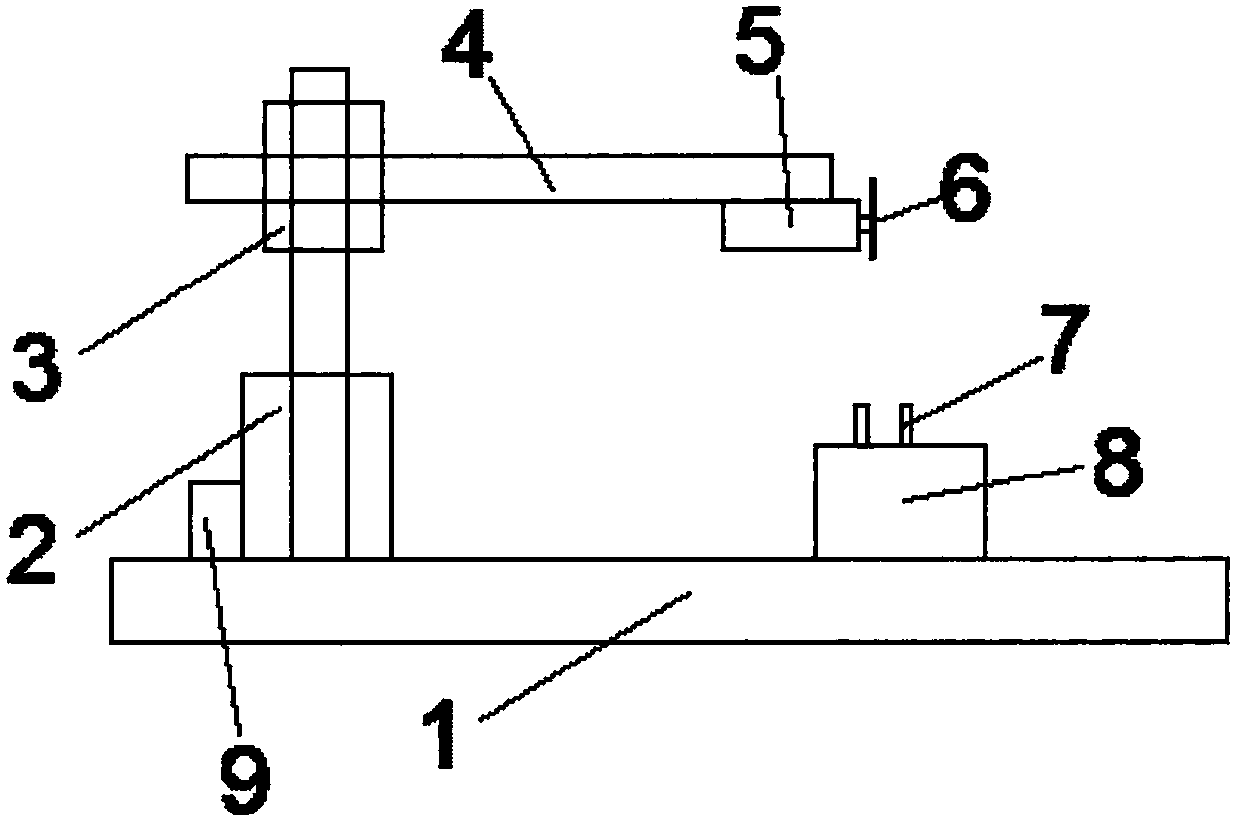

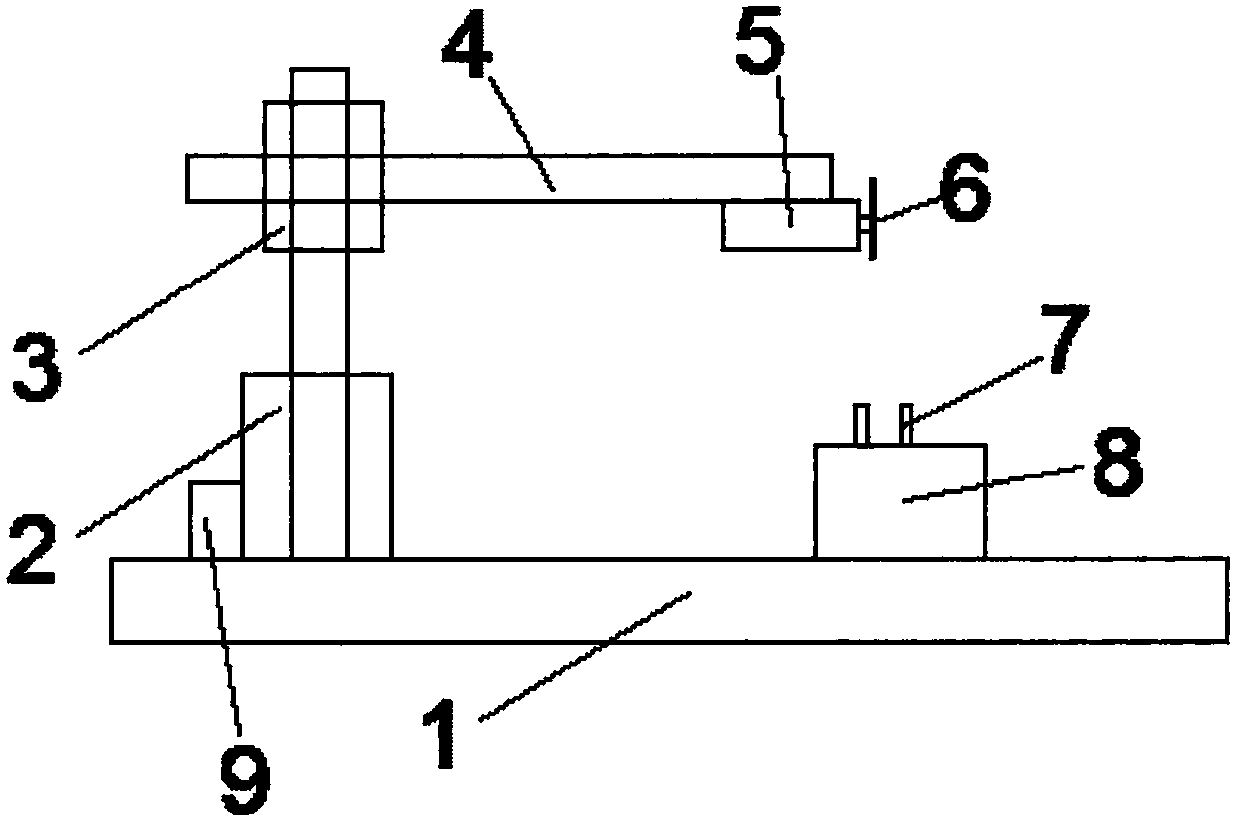

[0015] like figure 1 As shown, the present invention provides a hardware cutting device, including a base 1, a telescopic rod 2 and a motor 5, the left side of the base 1 is equipped with the telescopic rod 2, and the left side of the telescopic rod 2 A control device 9 is installed, and a connecting seat 3 is installed on the top of the telescoping rod 2, and the connecting seat 3 is horizontally fixed with a transverse bar 4, and a motor 5 is installed on the head of the transverse bar 4, and the head of the motor 5 is installed There is a cutting machine 6, a cutting seat 8 is placed directly below the cutting machine, and a fixing device 7 is fixed above the cutting seat 8.

[0016] The motor 5 is a servo motor.

[0017] The telescopic rod 2 can be stretched up and down.

[0018] The control device 9 controls the operation of the telescopic rod 2 and the motor 5 .

[0019] The motor 5 drives the cutting machine 6 to run.

[0020] The main feature of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com