Adjustable door and window profile cutting and grooving equipment

A door and window profile and slotting equipment technology, which is applied in the direction of shearing machine equipment, metal processing equipment, shearing devices, etc., can solve the problem that the cutting position and size of door and window profiles are difficult to accurately control, and the finished door and window cutting operation, slotting position and Dimensional deviation and other issues, to achieve the effect of meeting the needs of high-altitude operations, adjusting the cutting position, and making the cutting position easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

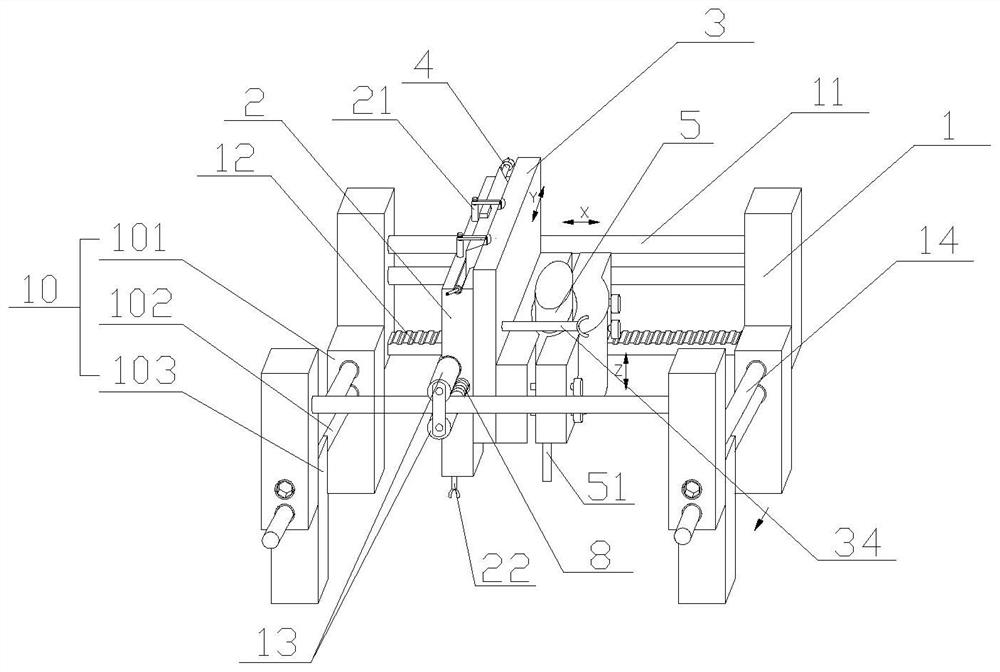

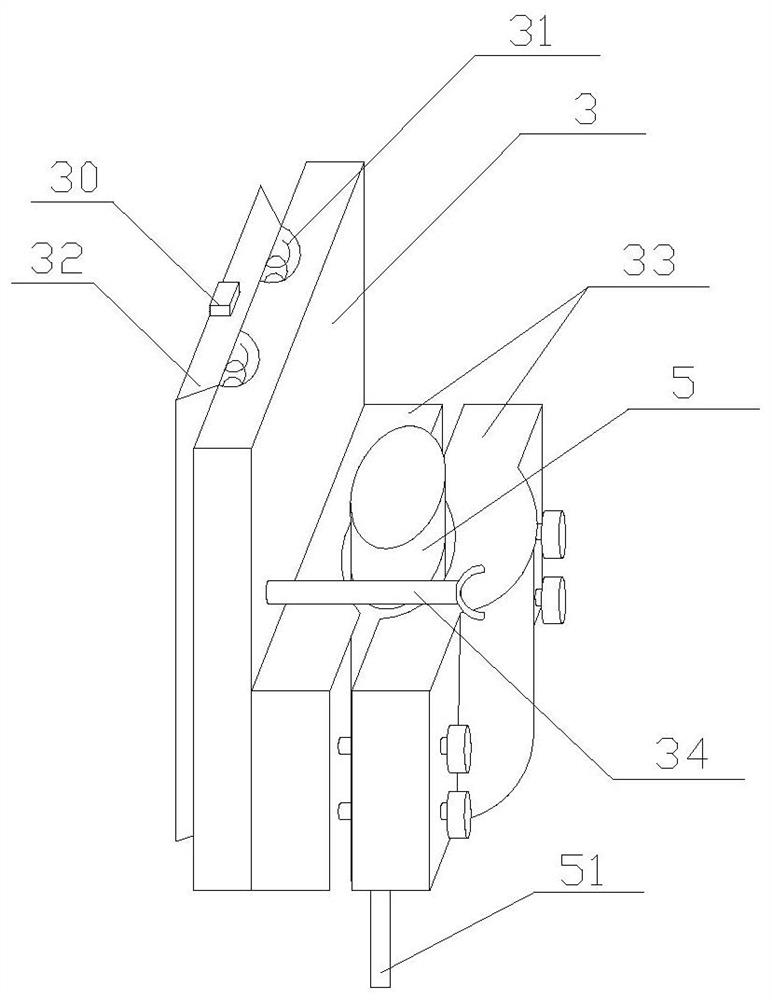

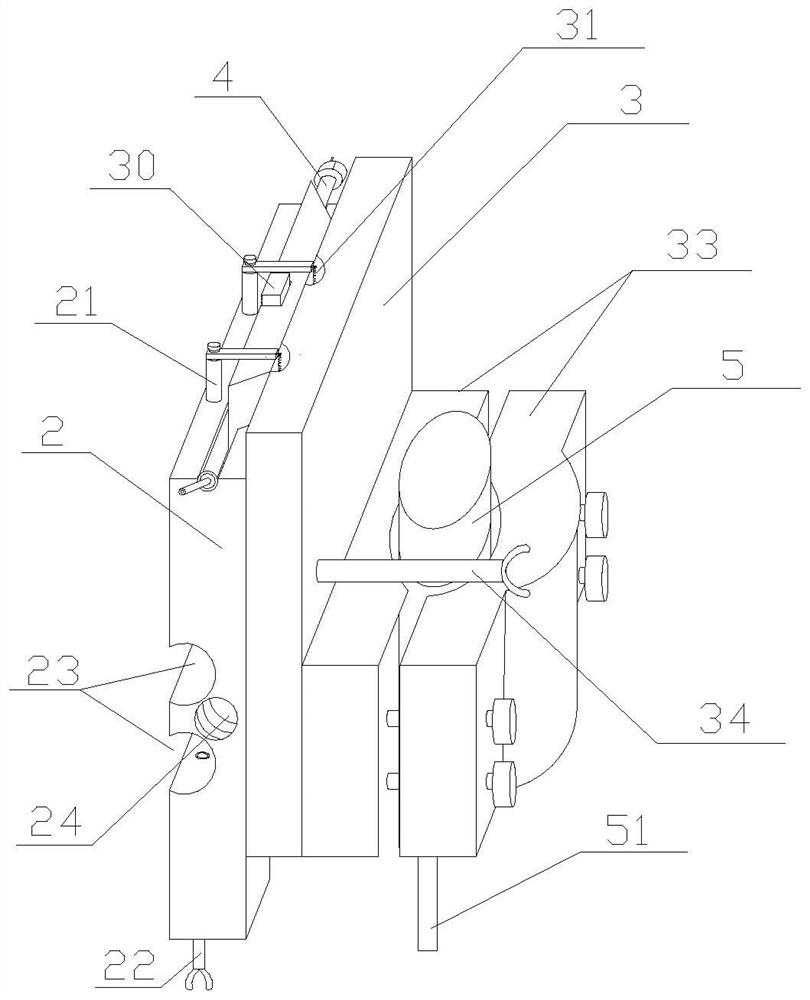

[0030] see Figure 1 to Figure 9 , this embodiment provides an adjustable door and window profile cutting and grooving equipment, including:

[0031] rack 1;

[0032] The sliding plate 2, the sliding plate 2 is installed on the frame 1, and drives the sliding plate to move back and forth on the frame 1 along the X-axis direction and the Y-axis direction through the X-axis driving mechanism 7 and the Y-axis driving mechanism 8, and the sliding plate 2 moves to the X-axis and The Y axis is fixed after the predetermined position;

[0033] Lifting seat 3, the lifting seat 3 is slidably installed on the sliding plate 2, and the lifting seat 3 is driven to move up and down on the sliding plate 2 along the Z-axis direction by the Z-axis drive mechanism 4. A cutting tool 51 and a driving device 5 connected to the cutting tool 51 are installed, and the driving device 5 includes a motor;

[0034] The adjusting and locking mechanism 10 is installed on the frame 1 to fix the frame 1 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com