Indoor decorative stone laying equipment and process

A technology for interior decoration and stone materials, which is applied in the direction of architecture and building construction. It can solve the problems of machine jamming, inability to pick up mortar at fixed points, and easy accumulation of additives, etc., and achieve the effect of consistent mortar volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

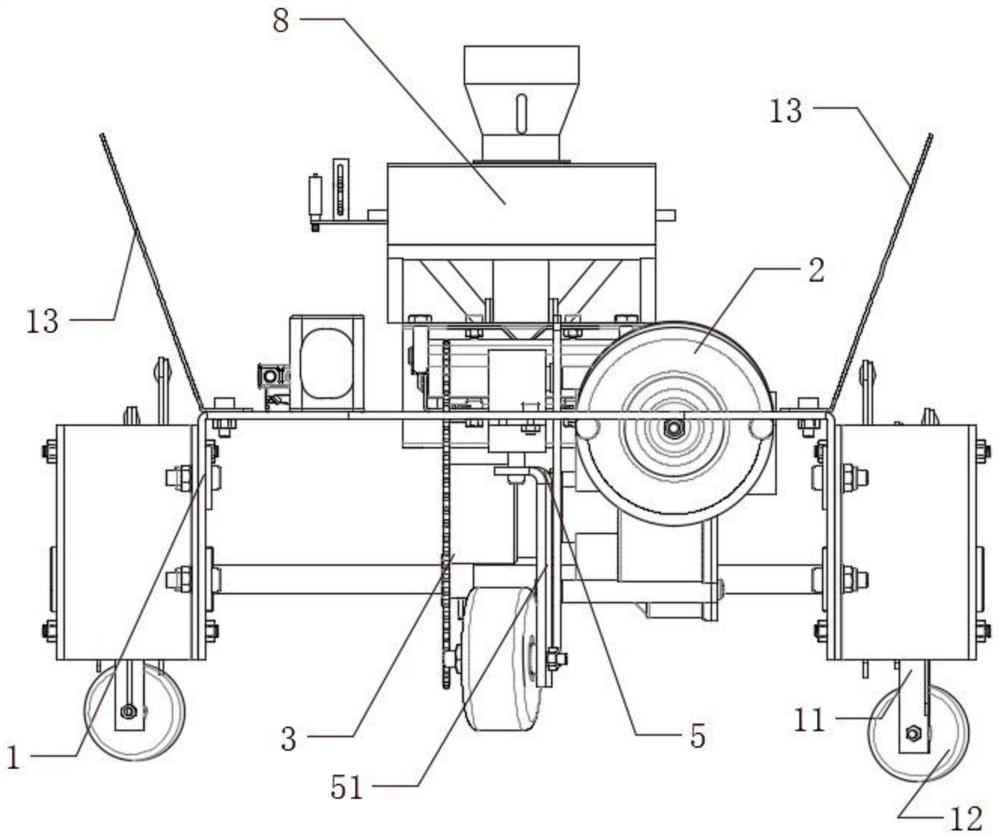

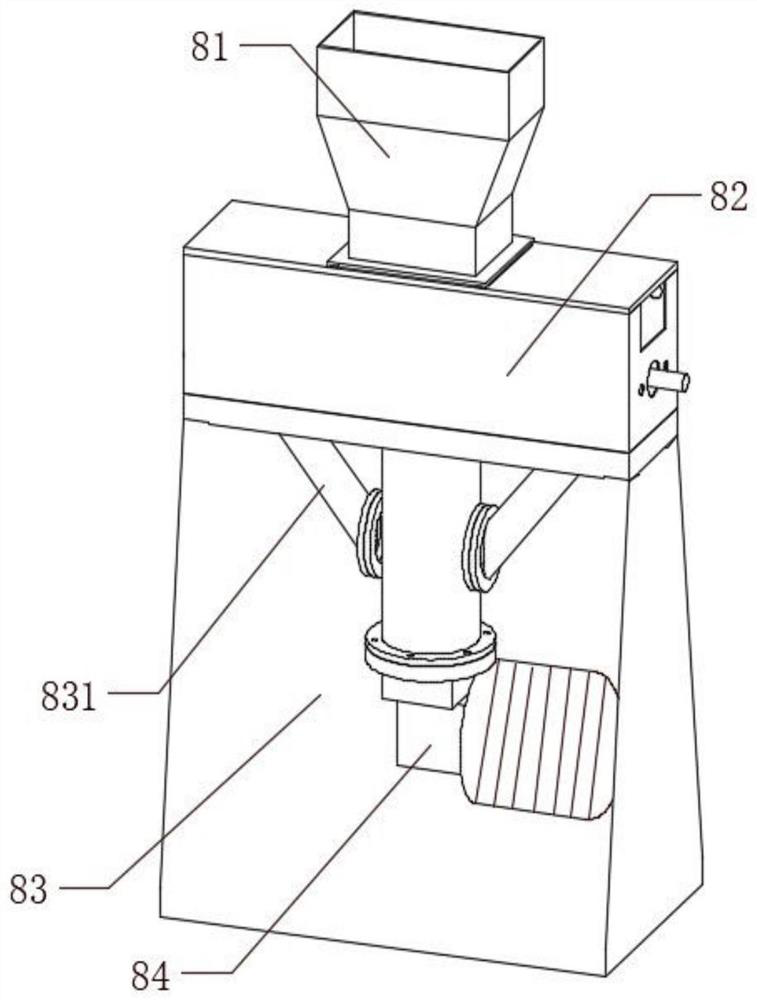

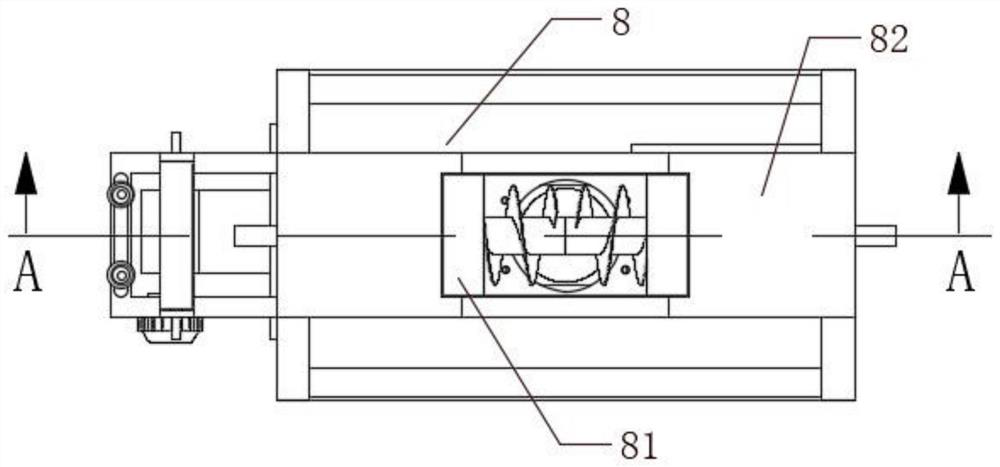

[0051] An indoor decorative stone laying equipment, comprising a driving mechanism 1, a power mechanism 2 and a cutting mechanism 3, the power mechanism 2 and the cutting mechanism 3 are arranged at the lower end of the driving mechanism 1 and connected with the driving mechanism 1, and the upper end of the driving mechanism 1 is also provided with The brick body sizing device 8, the brick body sizing device 8 is a guide cover body 81, a material adding part 82, and a mixing part 83 from top to bottom. The first material unit 821 and the second material pushing unit 822 rotate to stir the material and push it to both sides. The outside of the mixing part 83 is provided with a connecting cylinder 831 and a valve body 832 for controlling the flow of the material. The mixing part 83 passes through the connecting cylinder 831. It communicates with the feeding part 82, and the mixing part 83 is provided with a mixing unit 833. When the mixing unit 833 stirs and pushes the material u...

Embodiment 2

[0064] Embodiment As a further improvement of the previous embodiment, as Figure 1-7 As shown, a kind of indoor decorative stone laying equipment of the present invention comprises a driving mechanism 1, a power mechanism 2 and a cutting mechanism 3, the power mechanism 2 and the cutting mechanism 3 are arranged at the lower end of the driving mechanism 1 and connected with the driving mechanism 1, and the driving mechanism The upper end of 1 is also provided with a brick body sizing device 8, and the brick body sizing device 8 is a guide cover body 81, a material adding part 82, and a mixing part 83 from top to bottom. The second material unit 822, the first material pushing unit 821 and the second material pushing unit 822 rotate to stir the material and push it to both sides. The outside of the mixing part 83 is provided with a connecting cylinder 831 and a valve body 832 for controlling the flow of the material. The mixing part 83 communicates with the feeding part 82 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com