Combined hydraulic retarder

A hydraulic retarder, combined technology, applied in the direction of hydraulic resistance brakes, brake types, mechanical equipment, etc., can solve the problems of increasing the difficulty of manufacturing and installation, and achieve the effects of simple disassembly, easy manufacturing and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

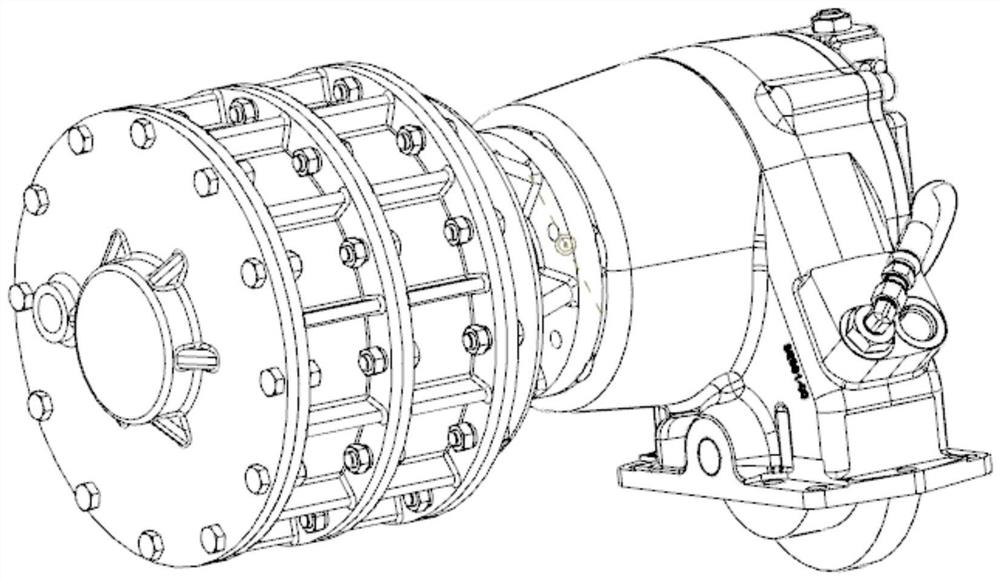

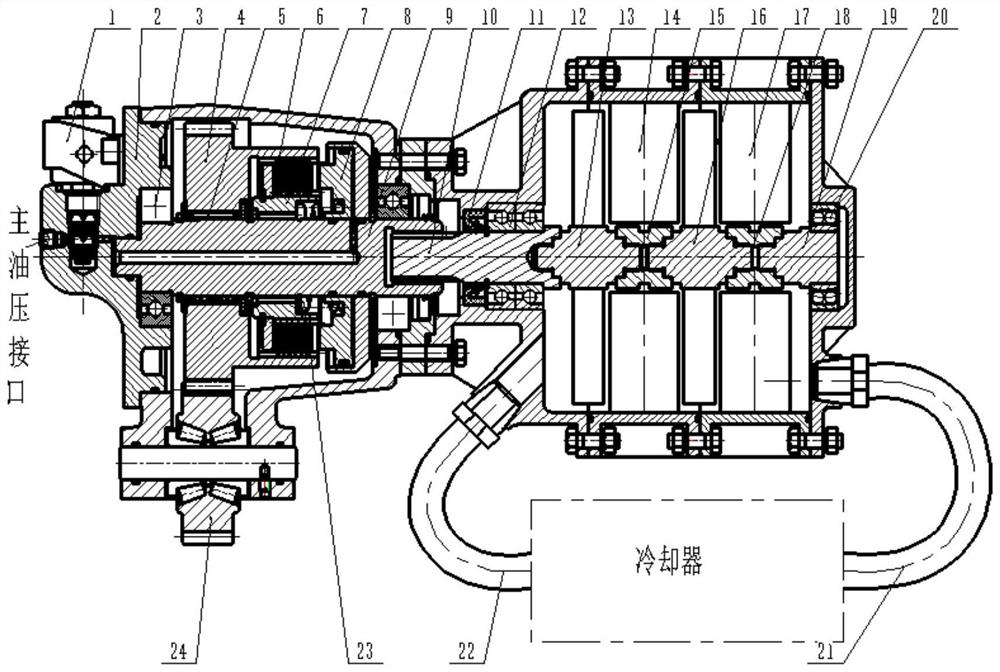

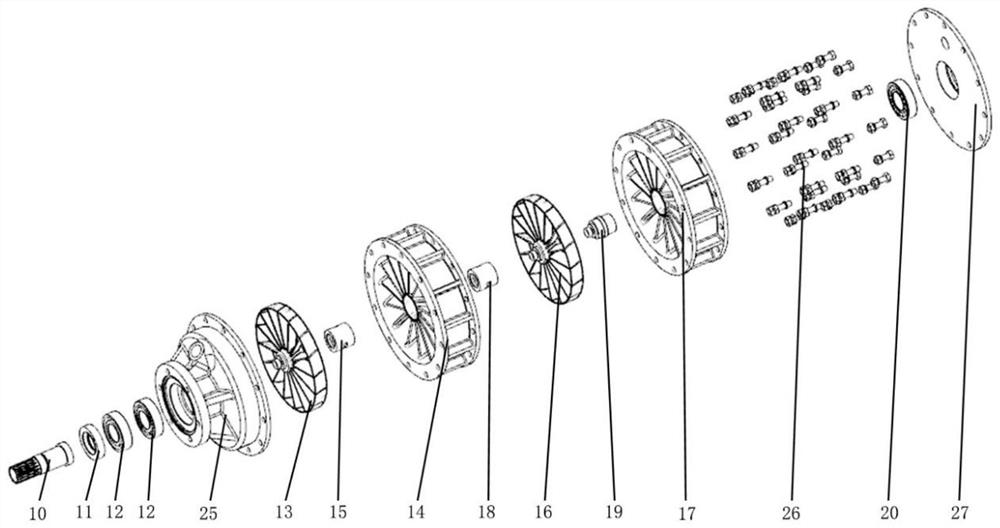

[0020] Such as Figure 1 to Figure 3 A combined hydraulic retarder shown includes a power take-off input gear 24; the power take-off input gear 24 meshes with a transmission power take-off gear hub 4, and a spline gear hub 7 is installed on the power take-off gear hub 4, The end of the spline gear hub 7 close to the power take-off gear hub 4 is equipped with a clutch friction plate 6, the spline gear hub 7 is fixed on the piston 8, and the movement of the piston 8 is controlled by the main oil pressure interface pipeline; the spline gear hub 7 Coaxial meshing transmission retarder assembly, electric drive rotation structure composed of multiple sets of stators and rotors coaxially installed in the retarder assembly.

Embodiment 2

[0022] Based on Embodiment 1, and, the moving direction of the piston 8 and the rotational axis of the power take-off gear hub 4 are located on the same straight line.

Embodiment 3

[0024] Based on Embodiment 1, and the retarder assembly is connected with a cooler through a rubber oil outlet pipe 21 and a rubber oil inlet pipe 22 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com