Manufacturing process of multi-protection temperature sensor

A technology of temperature sensor and manufacturing process, which is used in thermometer parts, thermometers, instruments, etc., can solve the problems of inability to rapidly reduce the temperature of flame and spray, inability to provide multiple protections for sensors, and the need to improve explosion-proof performance. The effect of protection, explosion-proof effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

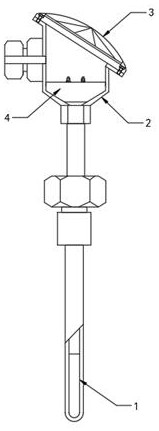

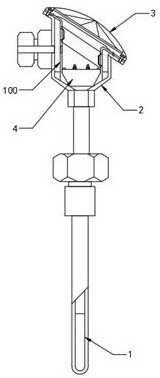

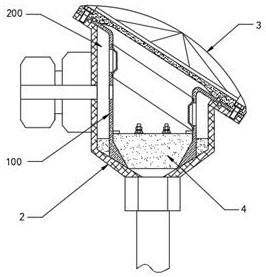

[0027] Such as Figure 1-3 As shown, an embodiment of the present invention proposes a manufacturing process of a multiple protection temperature sensor, the temperature sensor includes a temperature sensing probe 1, a flameproof member 100, a junction box 2 and a box cover 3, and the manufacturing process includes the following steps:

[0028] S1. Design a flameproof member 100 with a cylindrical structure including a pressure relief port 101, a ceramic sheet connecting piece 102 that is damaged and broken under the action of an external force, and a top end flange 103 that is sealed and connected inside the pressure relief port 101. Preparation Temperature probe 1, flameproof member 100, junction box 2 and box cover 3;

[0029] S2. Pre-install the flameproof part 100 in the junction box 2, form an outer flameproof cavity 200 between the flameproof part 100 and the inner wall of the junction box 2, and embed the electrician's seat 4 in the bottom of the inner cavity of the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com