Cable suspension part for overhead line

A technology of overhead lines and suspension parts, which is applied in the electric power field, can solve problems such as increased vibration amplitude, insulation layer wear, and potential safety hazards, and achieve the effects of reducing vibration amplitude, increasing friction force, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

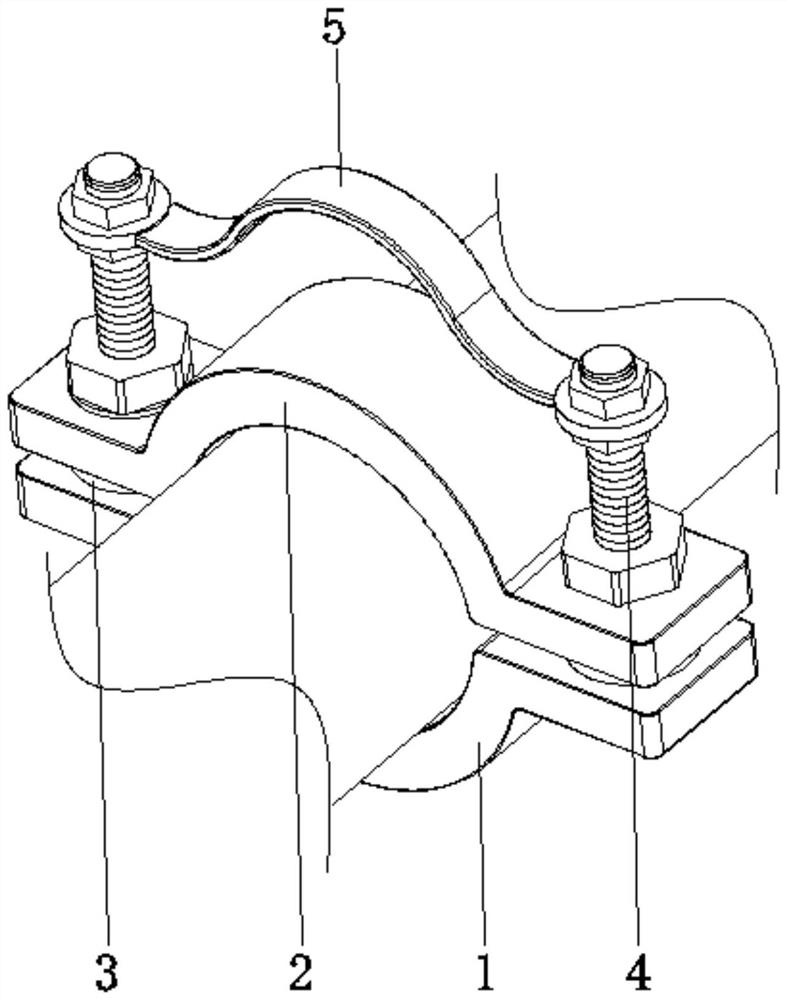

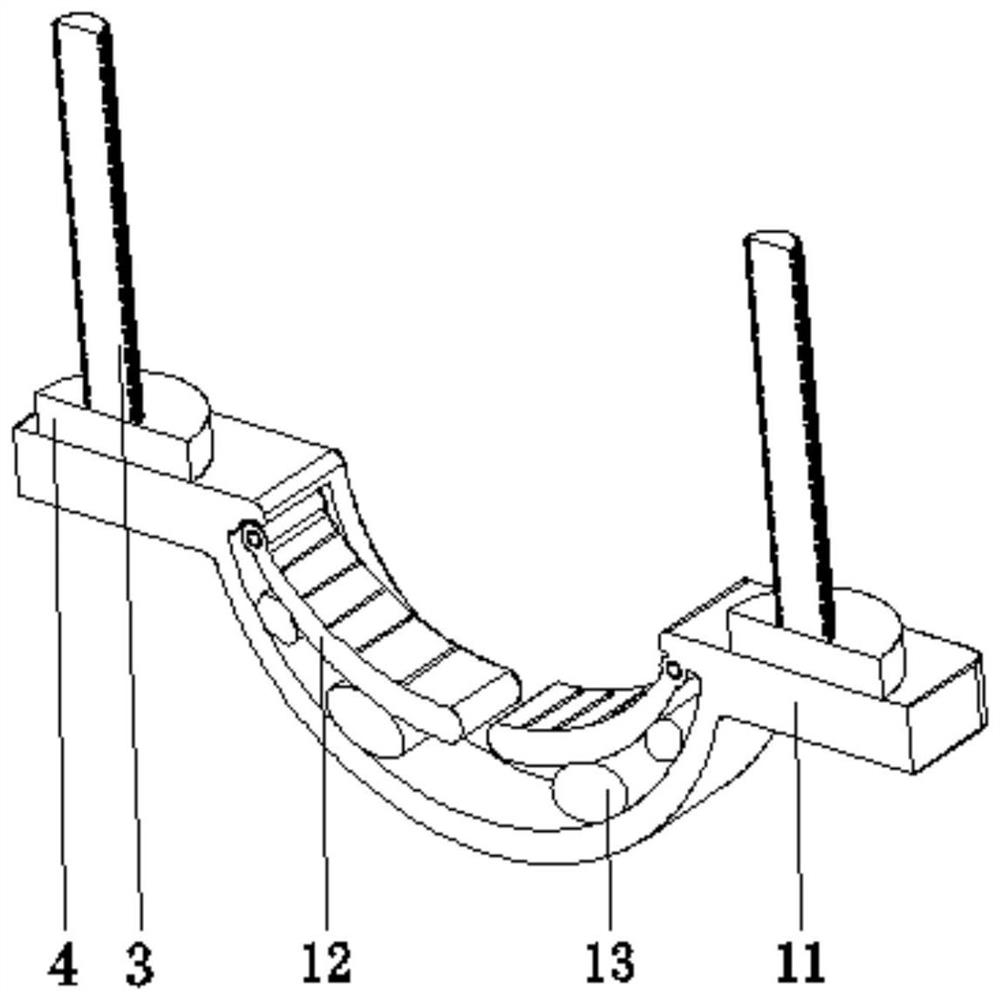

[0029] see Figure 1-5 , the present invention provides a technical solution: a cable suspension for overhead lines, including a base device 1, a pressing device 2, a jacking boss 3, a connecting stud 4, and a connecting piece 5, and the pressing device 2 is arranged on the base On the top of the seat device 1, the jacking boss 3 is fixed on the two sides corresponding to the top of the base device 1 and close to the end position, the base device 1 and the pressing device 2 are connected through the jacking boss 3, and the connecting screw The column 4 is vertically fixed on the top central position of the jacking boss 3, the pressing device 2 is connected with the connecting stud 4, and the base device 1 and the pressing device 2 are fixedly connected with the connecting stud 4 through a nut, and the connection Part 5 is fixed on the top of connecting stud 4 through nuts, and the cable is elastically clamped, which reduces the vibration amplitude, reduces the wear on the insu...

Embodiment example 2

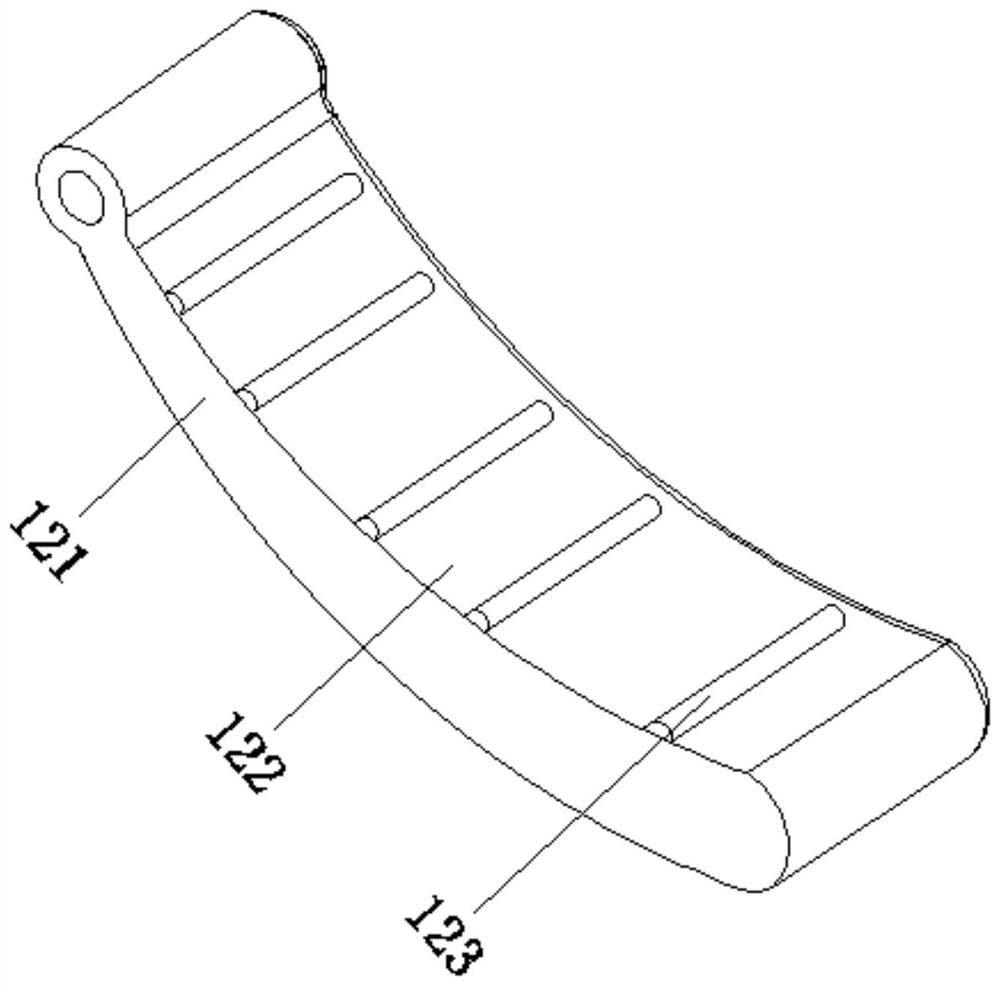

[0033] The pressing device 2 is provided with a semicircular pressing body 21, a circular groove 22, an annular air bag 23, a pressing plate device 24, an elastic bag body 25, and an airway 26, and the circular groove 22 is provided at the bottom of the semicircular pressing body 21 and Located at the position of the raised boss 3, the annular airbag 23 is arranged inside the semicircular pressing body 21 and at the position of the circular groove 22, the pressing plate device 24 is rotatably connected to the inside of the semicircular pressing body 21, and the elastic capsule body 25 It is arranged between the two sides corresponding to the inner wall of the semicircular pressing body 21 and the surface of the pressing plate device 24. The elastic capsule body 25 is connected with the pressing plate device 24. The air channel 26 is opened inside the semicircular pressing body 21. The boss 3 cooperates with the circular groove 22, and compresses the annular airbag 23 under the ...

Embodiment example 3

[0036] By setting the base device 1, the pressing device 2, the jacking boss 3, the connecting stud 4, and the circular groove 22, the jacking boss 3 is inserted into the circular groove 22, and the base device 1 and the pressing The device 2 is positioned, and when it is fixed, it presses the annular airbag 23, so that the cable is elastically clamped, the vibration is resolved in time, the vibration amplitude is reduced, the clamping and fixing effect is improved, and the pressure life of the cable is extended , the whole device is connected together, no isolated structure exists, which improves the performance.

[0037] When in use, the cable is first fixed through the cooperation between the base device 1 and the pressing device 2. When clamping, the supporting device 12 is in close contact with the cable and presses the elastic rod 13, so that the cable is Elastic clamping has the effect of shock absorption, reducing the vibration amplitude, and when the cable is clamped,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com