Wave energy power generation device

A power generation device and wave energy technology, which is applied in the direction of ocean energy power generation, hydropower generation, engine components, etc., can solve the problems of reduced performance, low wave energy conversion efficiency, single power generation, etc., to achieve lubrication, improve work efficiency and use Performance, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

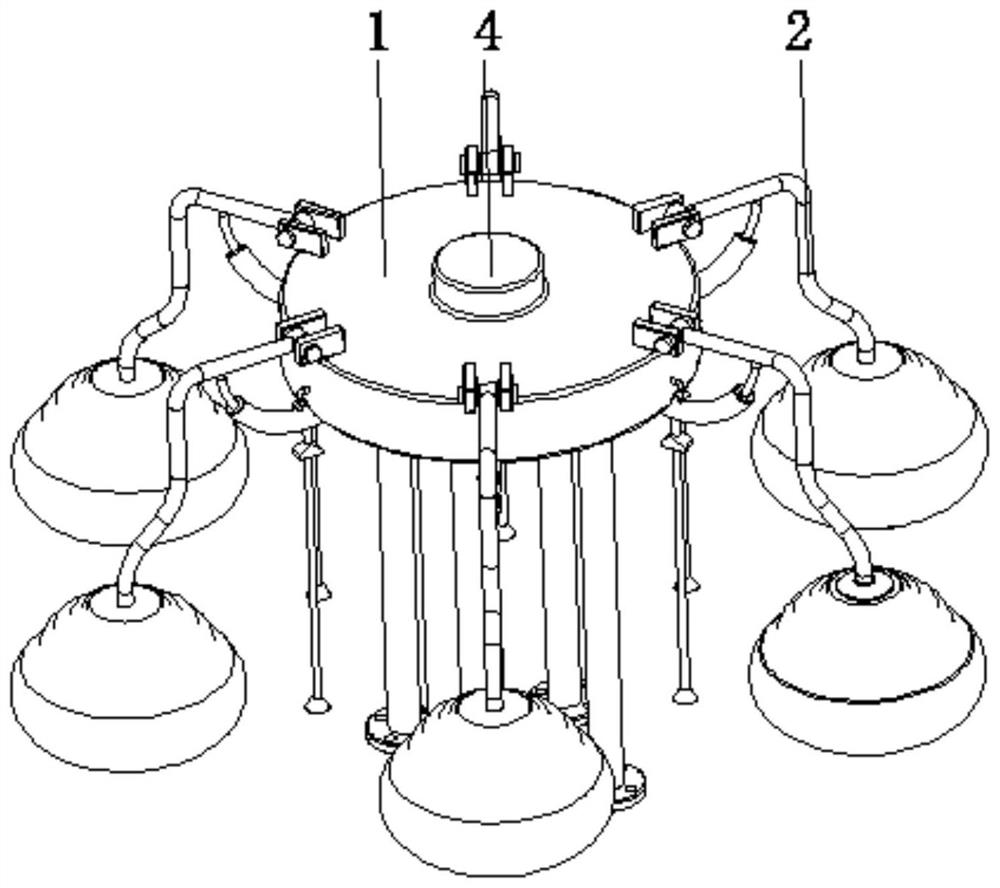

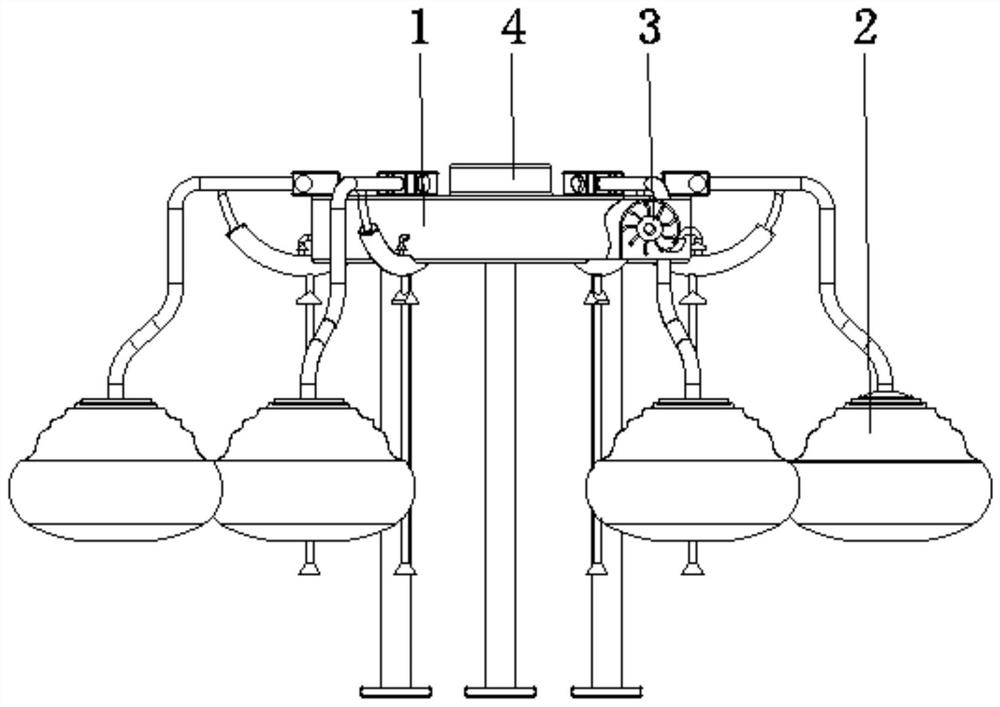

[0029] see Figure 1-6 , the present invention provides a technical solution: a wave energy power generation device, including a base body 1, a floating drive device 2, an impeller 3, and a first-stage power generation mechanism 4, the floating drive device 2 is arranged on the surface edge of the base body 1, and the impeller 3 is set Inside the base body 1 and close to the floating drive device 2, the first-stage power generation mechanism 4 is arranged at the top center of the base body 1;

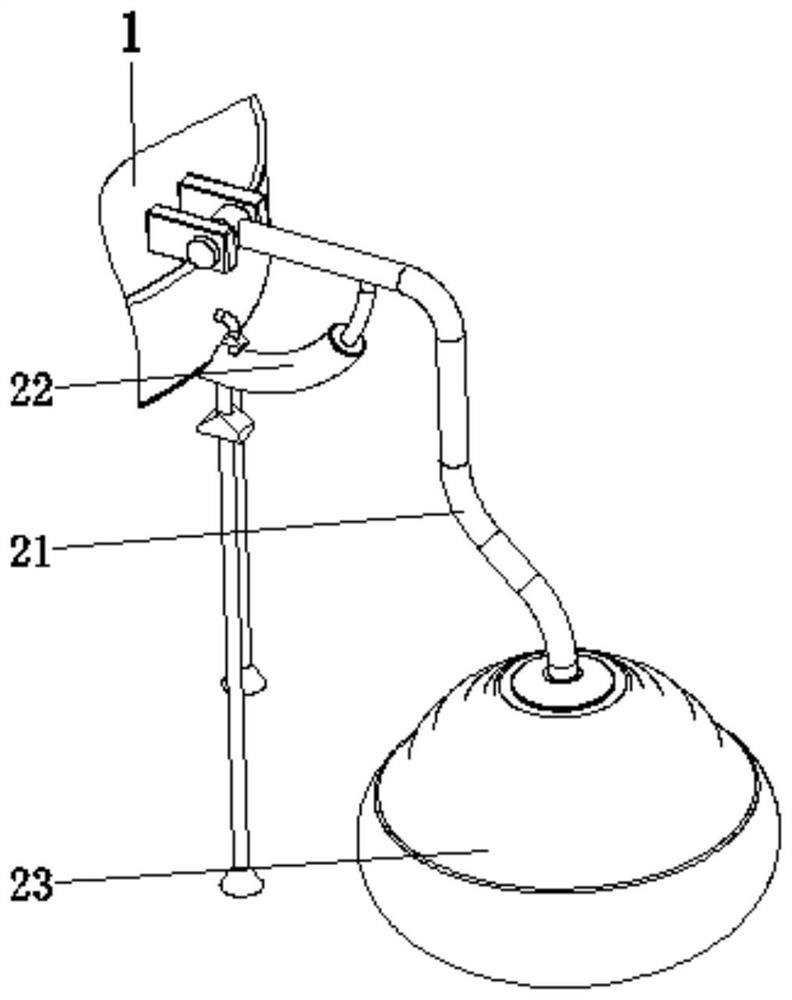

[0030] The floating driving device 2 is provided with a swing arm 21, a pressing device 22, and a float device 23. The top of the swing arm 21 is rotationally connected to the top edge of the base body 1, and the pressing device 22 is arranged on both sides corresponding to the surface of the swing arm 21 and the surface of the base body 1. In between, the buoy device 23 is arranged at the bottom of the swing arm 21 to quickly convert the wave energy and generate electricity in multiple...

Embodiment example 2

[0032] The pressing device 22 is provided with an arc-shaped cylinder 221 and an arc-shaped piston 222. One end of the arc-shaped cylinder 221 is fixed on the bottom of the substrate 1 and is located at the edge position. The arc-shaped piston 222 is connected with the arc-shaped cylinder 221. The arc-shaped piston 222 The top of the top is fixedly connected with the surface of the swing arm 21, and the liquid outlet end of the arc-shaped cylinder 221 extends to the inside of the base body 1 and is located at the position of the impeller 3. Under the influence of wave energy, the float device 23 floats up and down, and then through the swing arm 21 pair The arc-shaped piston 222 pulls and presses down, and controls the direction of the liquid in and out through the liquid inlet check valve 2201 and the liquid outlet check valve 2202 to absorb and drain the seawater, and the discharged high-pressure water is sprayed to the impeller 3, Make it rotate at a high speed, so that the ...

Embodiment example 3

[0034] Float device 23 is provided with pillar 231, float housing 232, arc rack 233, gear 234, secondary generator 235, oil injection device 236, rubber membrane 237, and pillar 231 is arranged on the inside of float housing 232 and the top and swing arm The bottom end of 21 is fixedly connected, and the bottom end of pillar 231 is rotationally connected with the bottom of the inner wall of float housing 232. One end of arc rack 233 is fixed at the bottom of the inner wall of float housing 232 and is connected with the pillar 231. The gear 234 is arranged on The inside of the pillar 231 is engaged with the arc-shaped rack 233, the secondary power generation mechanism 235 is arranged on the surface of the pillar 231 and connected with the gear 234, and the fuel injection device 236 is arranged at the end of the arc-shaped rack 233 Between the two sides corresponding to the bottom of the inner wall of the float housing 232, the rubber membrane 237 is arranged between the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com