Active paddy field weeding device with self-adaptive weeding strength

An adaptive and active technology, which is applied in the field of mechanical weeding, can solve the problems that weeding parts are difficult to avoid effective control of weeds between rice plants, root zone weeds are difficult to effectively control, and it is difficult to ensure that the row operation is difficult to achieve. High-quality control, reduce the intensity of manual weeding, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with specific embodiments.

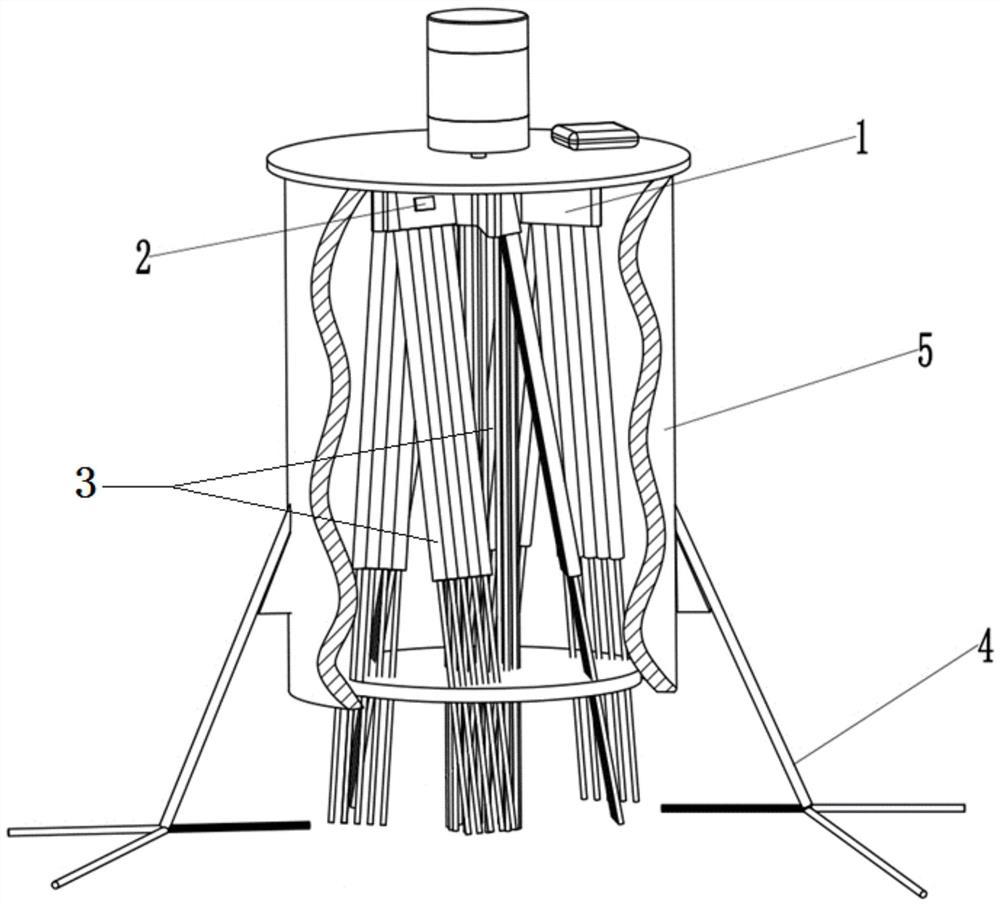

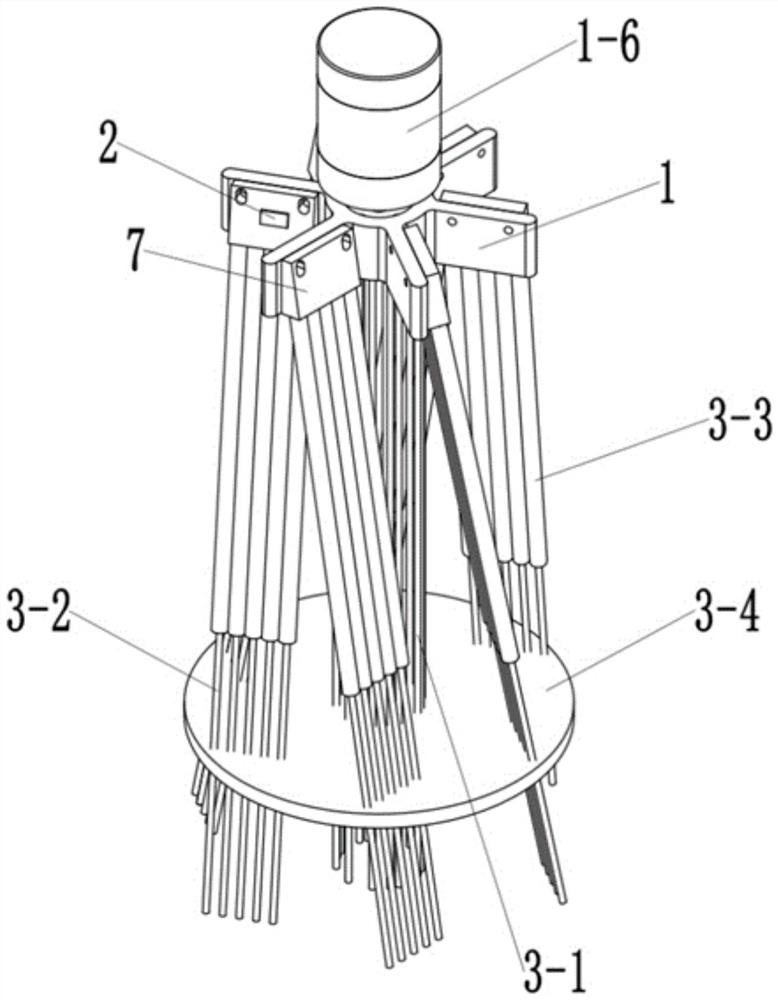

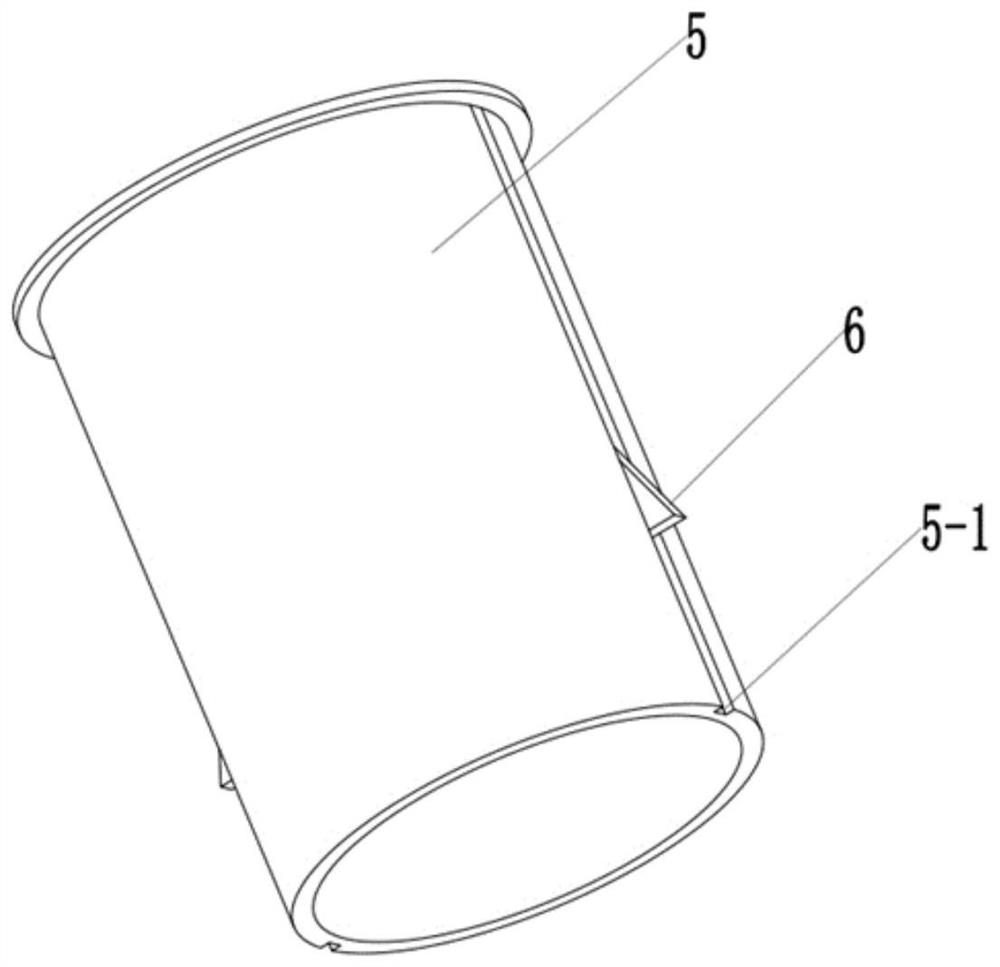

[0031] In the accompanying drawings of the present invention: 1. driving part; 2. sensory mechanism; 3. inter-row weeding part; 4. inter-row weeding part; 5. seedling protection cover; -1. Drive turntable; 1-2. Rotating arm; 1-3. Fixing hole for roller finger mounting block; 1-4. Rigid inter-row weeding roller finger mounting hole; 1-5. Motor fixing hole; 1-6. DC geared motor; 3-1. Rigid row weeding roller finger; 3-2. Flexible row weeding roller finger; 3-3. Pipe sleeve; 3-4. Restraining plate; .Inter-row weeding roller finger; 4-2-1. Inter-row flexible weeding roller finger; 4-2-2. Inter-row rigid weeding roller finger; 5-1. Chute; 7-1. Flexible inter-row weeding roller finger security jack;

[0032]The invention is an active paddy field weeding device with self-adaptive weeding intensity, which comprises an inter-row weeding part, an inter-row weeding part, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com