A weeding device integrating cutting and spraying

An integrated, spraying rod technology, which is applied in the direction of trapping or killing insects, equipment for weed elimination, agricultural machinery and implements, etc., can solve the problem of soil structure, nutrient damage, difficulty in removing weeds at the same time, and weeding rate No high-level problems, to achieve the effect of improving the operation effect, reducing the amount of spraying, and widening the weeding range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

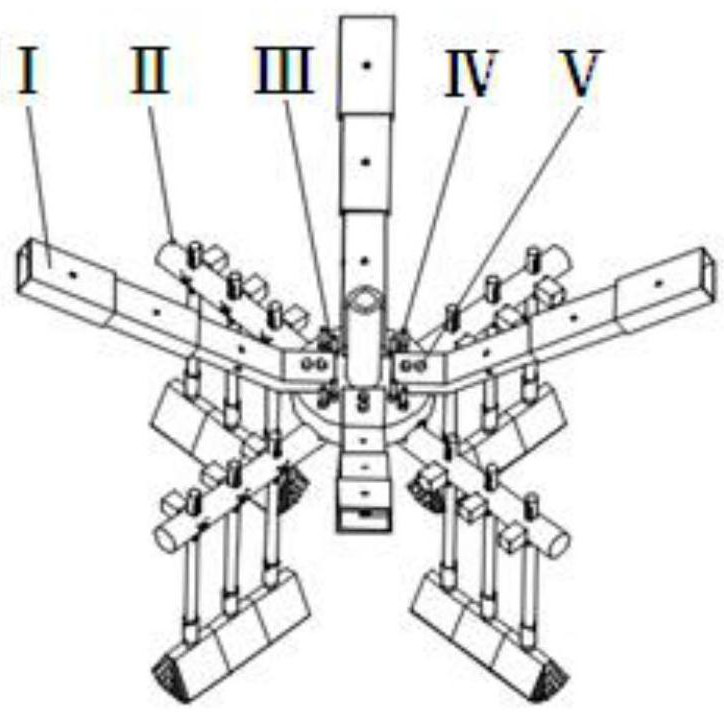

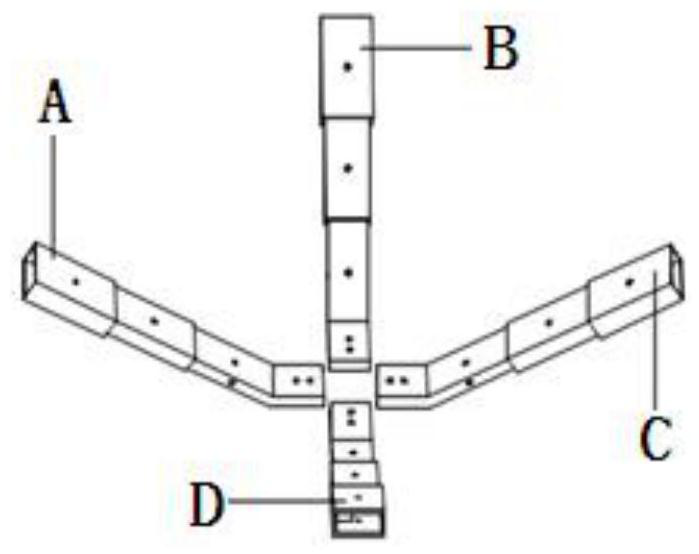

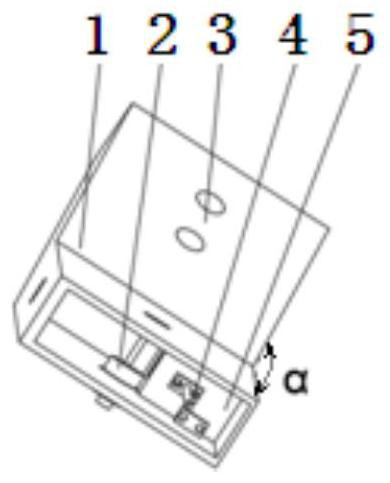

[0033] Such as figure 1 with figure 2 As shown, the present invention is composed of spraying part I, cutting part II, connecting assembly III, bolt group IIV and bolt group II V, wherein said bolt group IIV and bolt group II V are composed of four pairs of bolts, and the spraying part I The screw holes Ⅰ3 on the nozzle connecting plate 1 of the middle spraying rod aA, spraying rod bB, spraying rod cC and spraying rod dD are fastened to the through hole group in the connection assembly III through four pairs of bolts of the bolt group IⅣ The position of four pairs of through holes for I21; the screw holes II13 on the respective cutting connectors 14 of the cutting assembly aE, cutting assembly bF, cutting assembly cG and cutting assembly dH in the cutting assembly II are fixed through the four pairs of bolts of the bolt group II V The four pairs of throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com