Processing and making method of pre-conditioning quick-frozen fresh beans

A technology of quick-frozen fresh beans and a production method, which is applied in food freezing, fruit and vegetable preservation, and the functions of food ingredients, etc., and can solve problems such as loss of market competitiveness and product value, affecting people's appetite and taste, and incomplete preservation of fresh beans. , to achieve good application prospects, easy storage and transportation, and improve product quality and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0030] Aiming at the problems existing in the prior art, the present invention provides a method for processing pre-conditioned quick-frozen fresh beans. The present invention will be described in detail below in conjunction with the accompanying drawings.

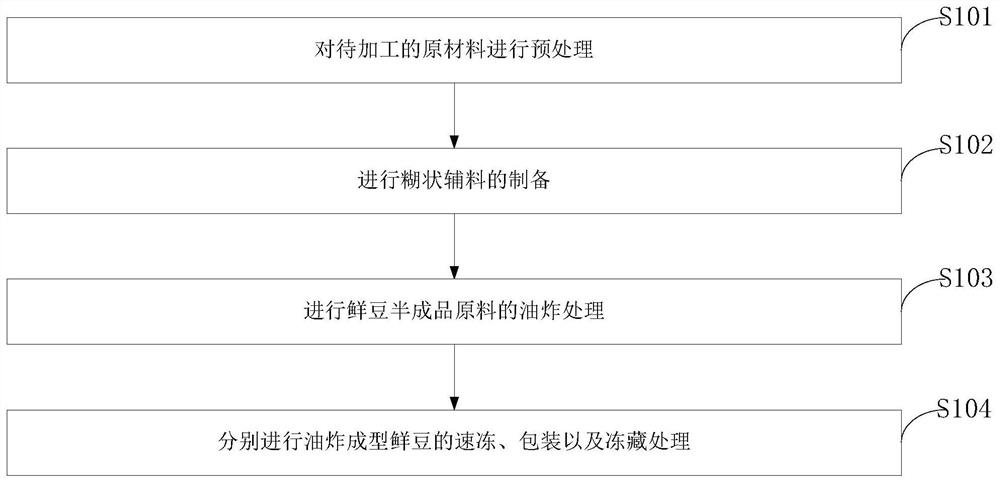

[0031] Such as figure 1 As shown, the processing method of the preconditioning quick-frozen fresh beans provided by the embodiment of the present invention comprises the following steps:

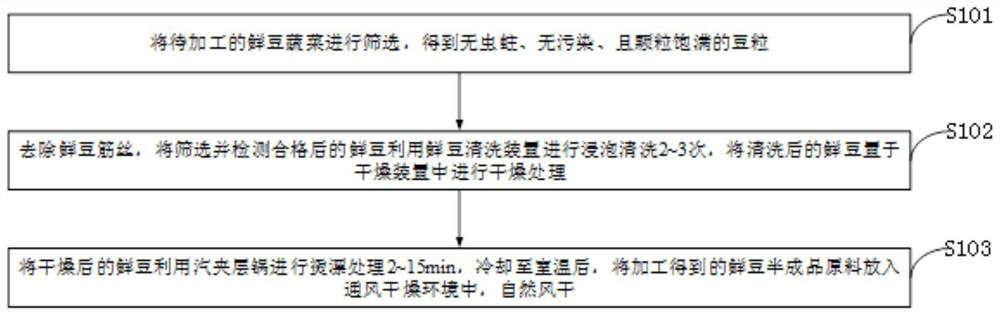

[0032] S101, pretreating the raw materials to be processed;

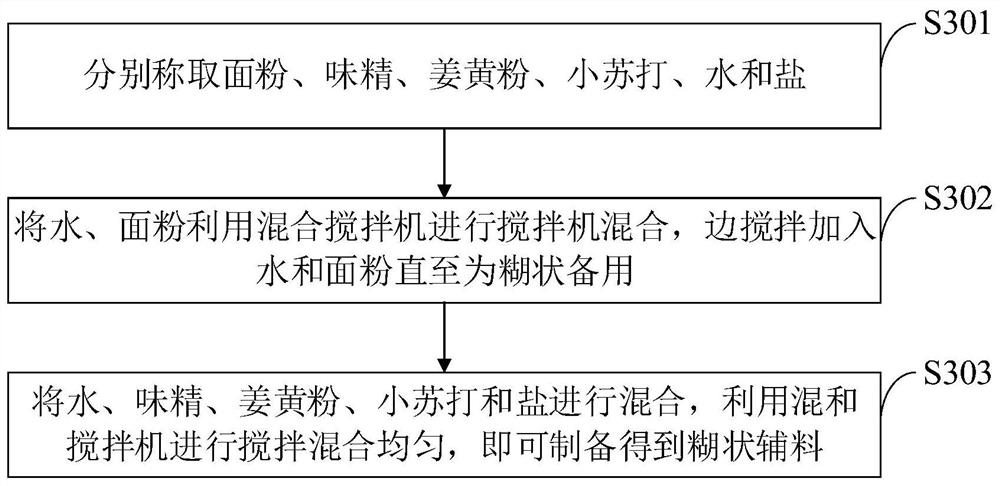

[0033] S102, preparing pasty auxiliary materials;

[0034] S103, performing frying treatment on raw materials of semi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com